Combination method mounting technique for ultra-large type steel converter

A steel-making converter and combined installation technology, which is applied in assembly machines, manufacturing converters, metal processing equipment, etc., can solve the problems of large engineering investment, installation of transmission devices that cannot be steel-making converters, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

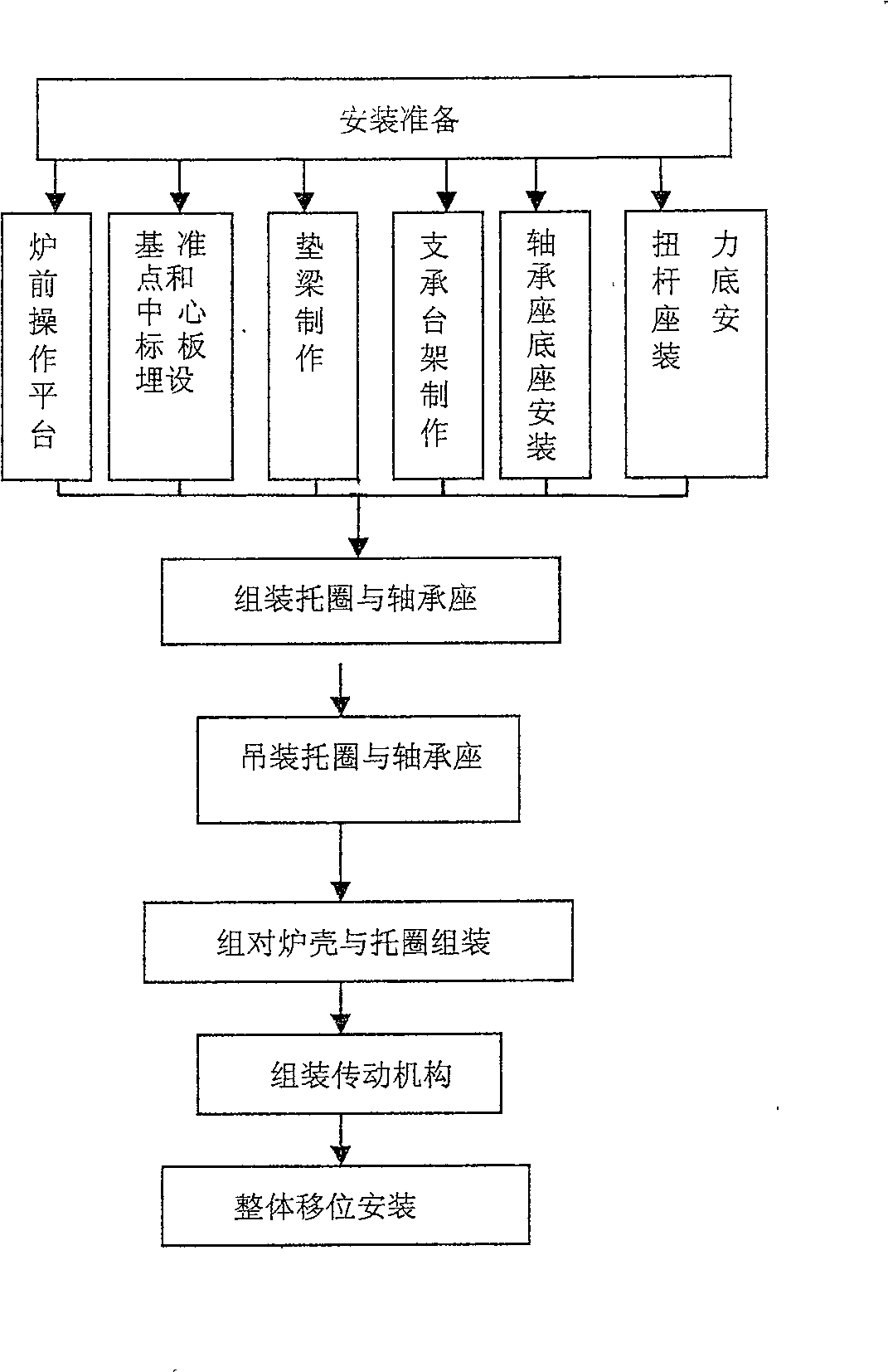

Method used

Image

Examples

Embodiment

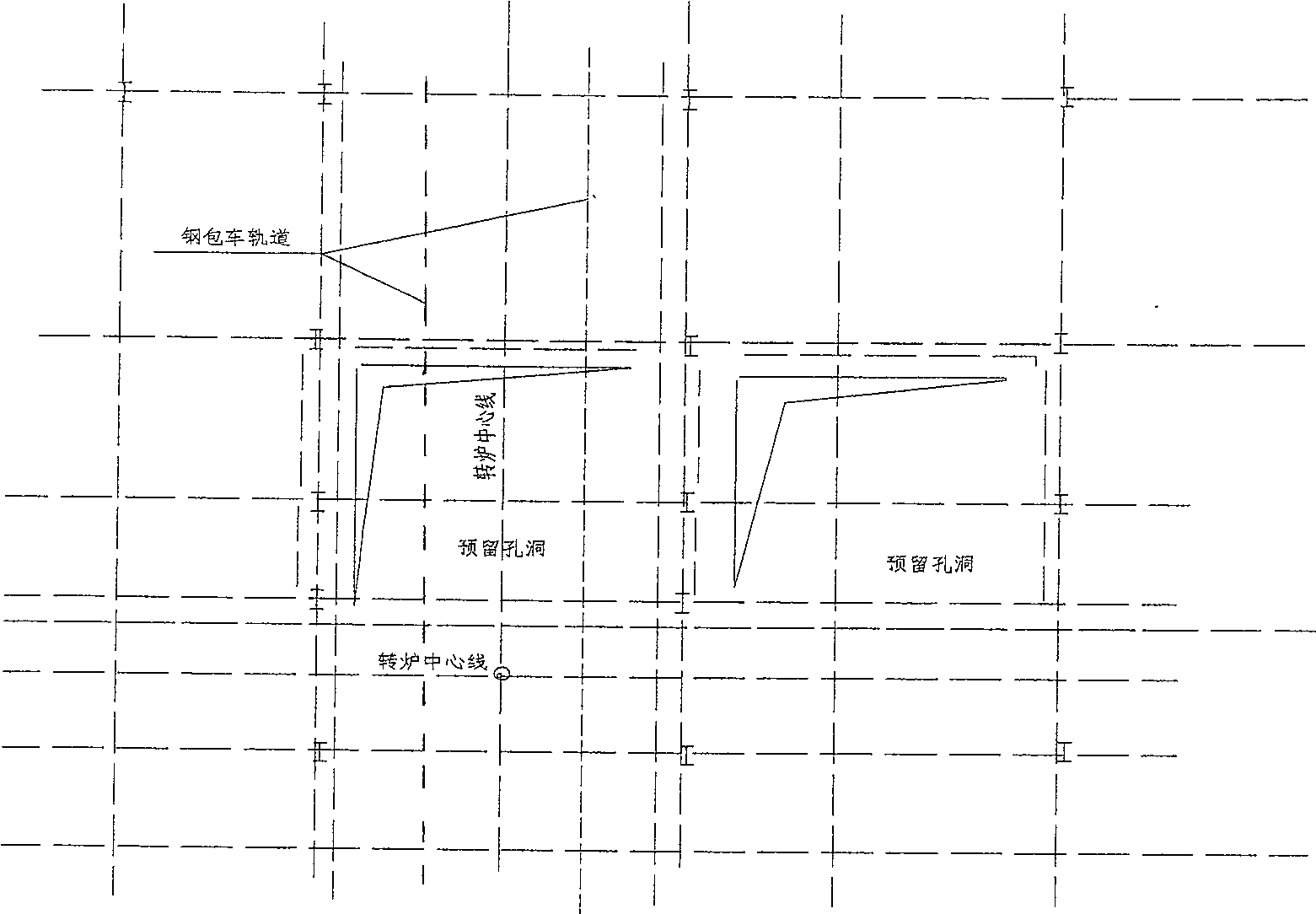

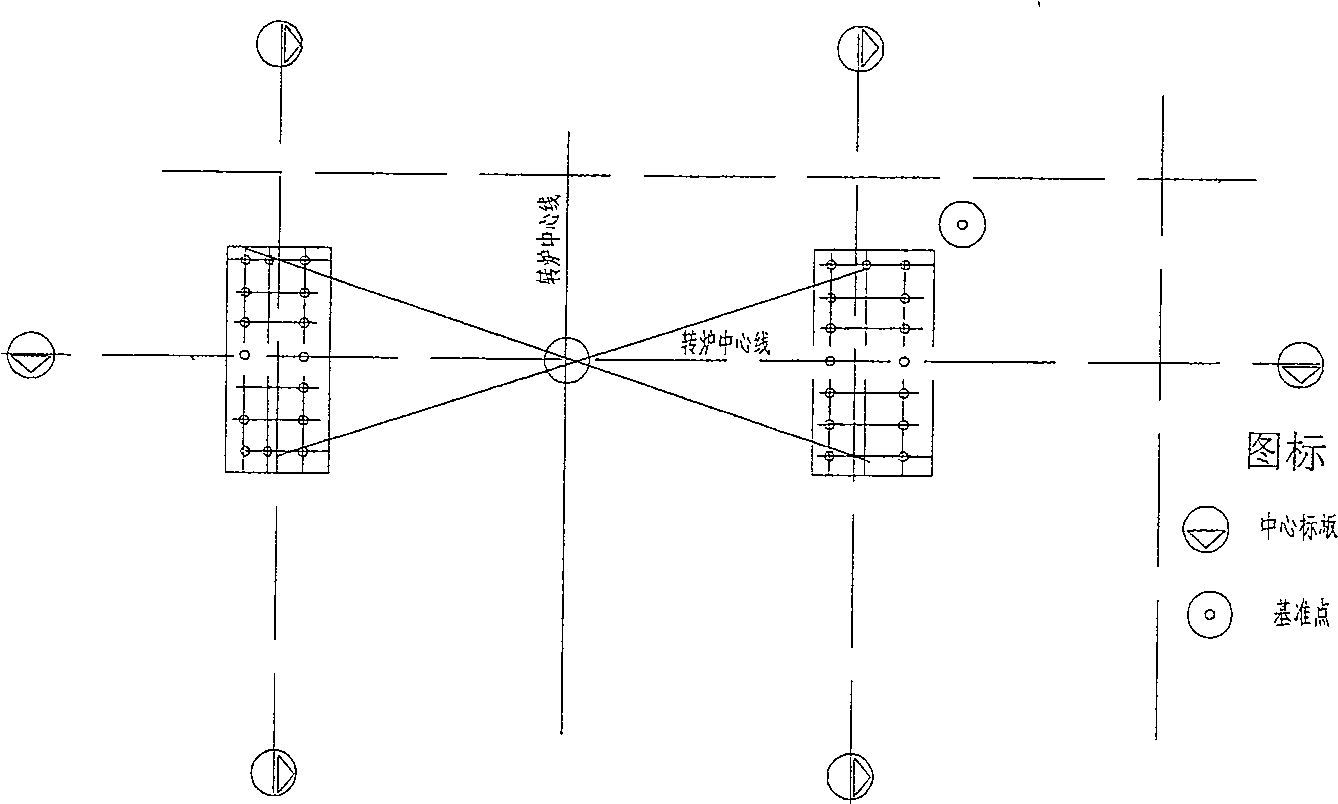

[0074] Example: Two 300t converters in Maanshan Iron and Steel New District, which were constructed by China No. 17 Metallurgical Construction Co., Ltd., were installed by combined installation method during construction. In the feeding span workshop with large bridge cranes, three converters were installed: Support ring and bearing seat: 302t, furnace shell and "voestalpine" Con Link three-point suspension device: 260t and transmission mechanism: 130t, assembled into a whole converter with a total weight of 692t; On the pad beam of the roller bar; the trolley, that is, the molten steel tanker, is towed by a 5t hoist and a 30t main pulley block for moving, and a 10t single pulley block and the main hook of the steelmaking straddle bridge are used for traction at the drive side bearing seat, and are jointly pulled to the installation position of the steelmaking straddle converter. The converter is installed in place as a whole.

[0075] The first converter began to move from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com