Labyrinth oil gas separator

A separation device, labyrinth technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of unreasonable structure layout, single baffle design, incomplete separation of oil and gas, etc., to achieve complete separation of oil and gas, The effect of protecting the environment and reducing oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

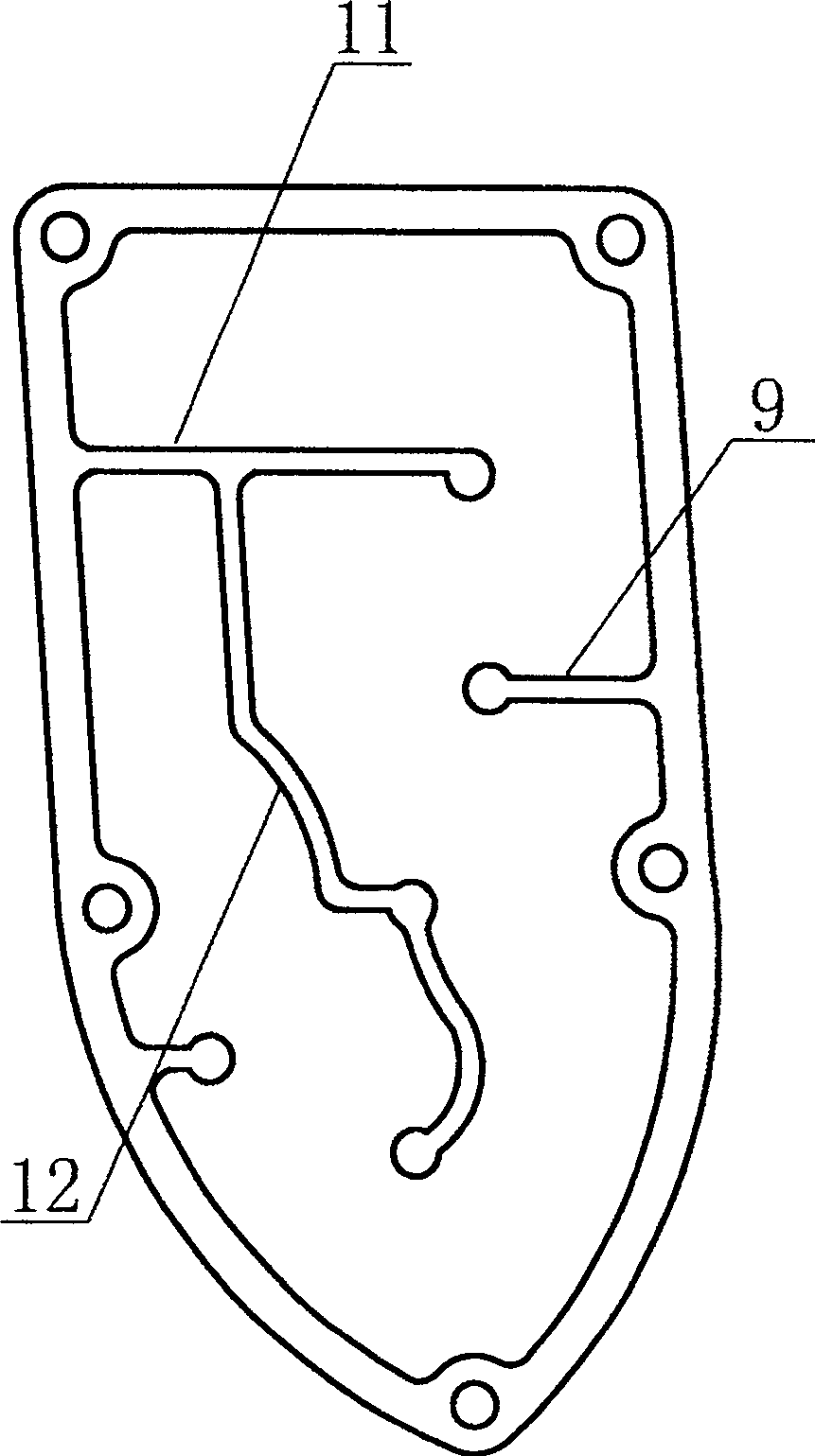

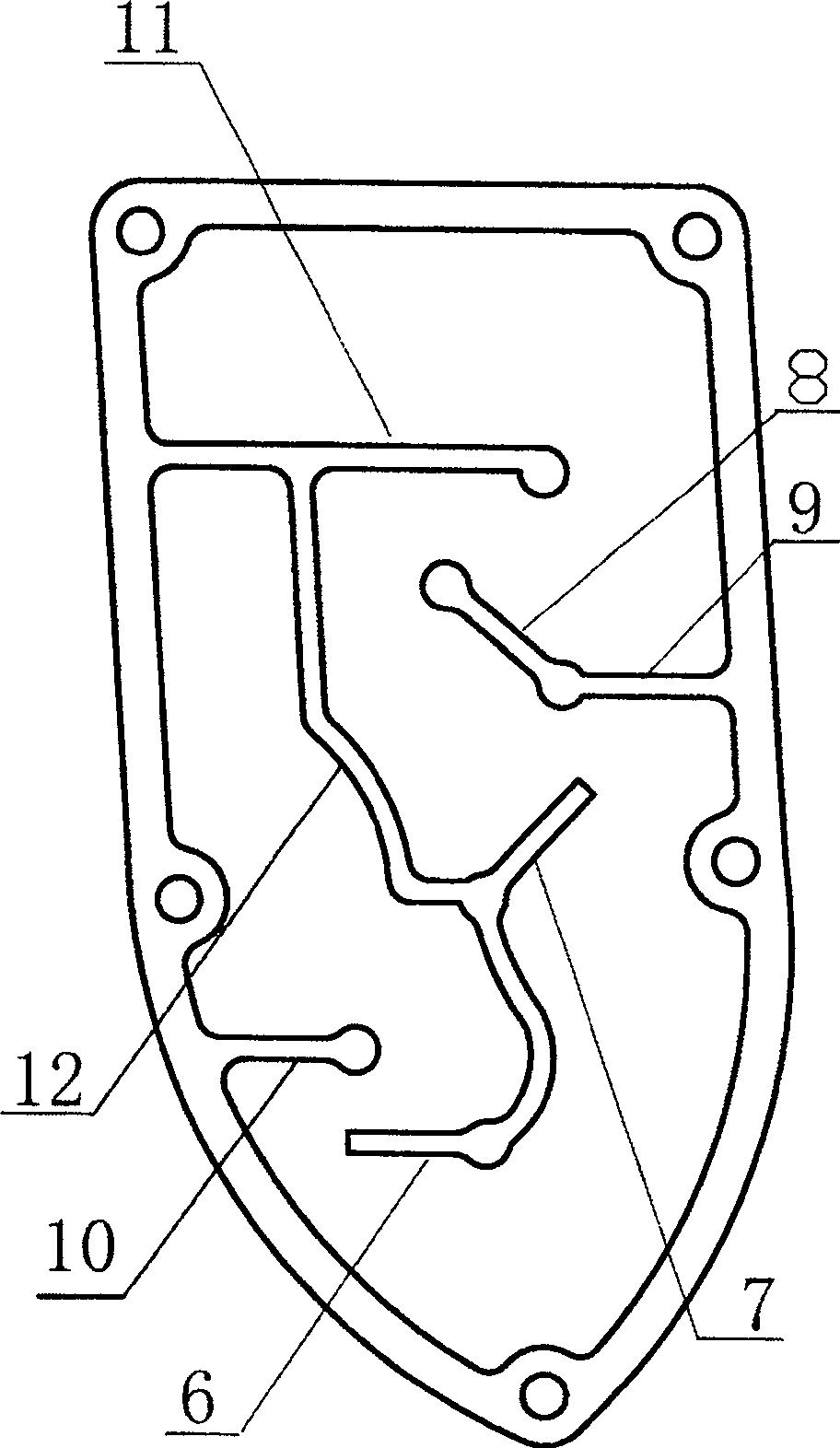

[0017] Example: such as figure 2 As shown, a transverse partition 11 and a medial partition 12 connected to it are provided on the inner side of the coaming plate arranged on the cylinder head cover. Wherein the mediastinum 12 comprises a vertical curved body and an arc body connected with it in a shape adapted to the lower part of the coaming plate waist, and a mediastinum guide plate 7 is obliquely provided at the junction of the two parts, and a mediastinum guide plate 7 is arranged obliquely at the tail of the arc body. A guide plate 6 arranged substantially parallel to the transverse partition 11; a waist partition 9 is also provided on the inner side of the coaming, and the waist partition 9 is basically parallel to the transverse partition 11; a waist partition guide plate 8 is obliquely provided at the end of the waist partition 9. The end points to the intersection of the transverse septum 11 and the mediastinum 12 or near the intersection, and a cylinder is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com