Synchronous drive method for parallel installation of multiple eccentric shafts

A synchronous drive, eccentric shaft technology, applied in the direction of transmission boxes, mechanical equipment, transmission devices, etc., can solve the problems of synchronous drive mechanism defects, low working reliability and service life of synchronous toothed belts, and inability to operate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

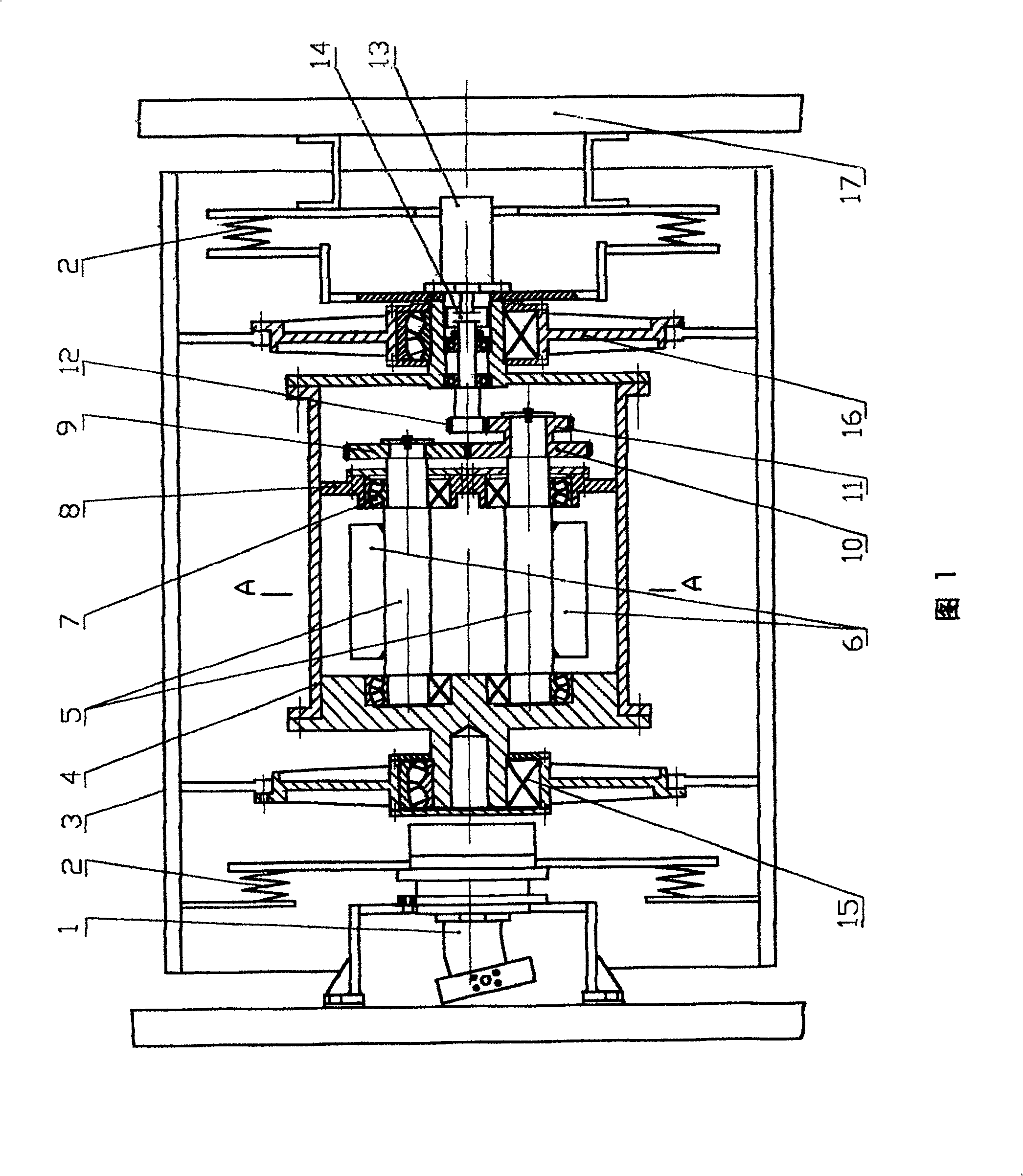

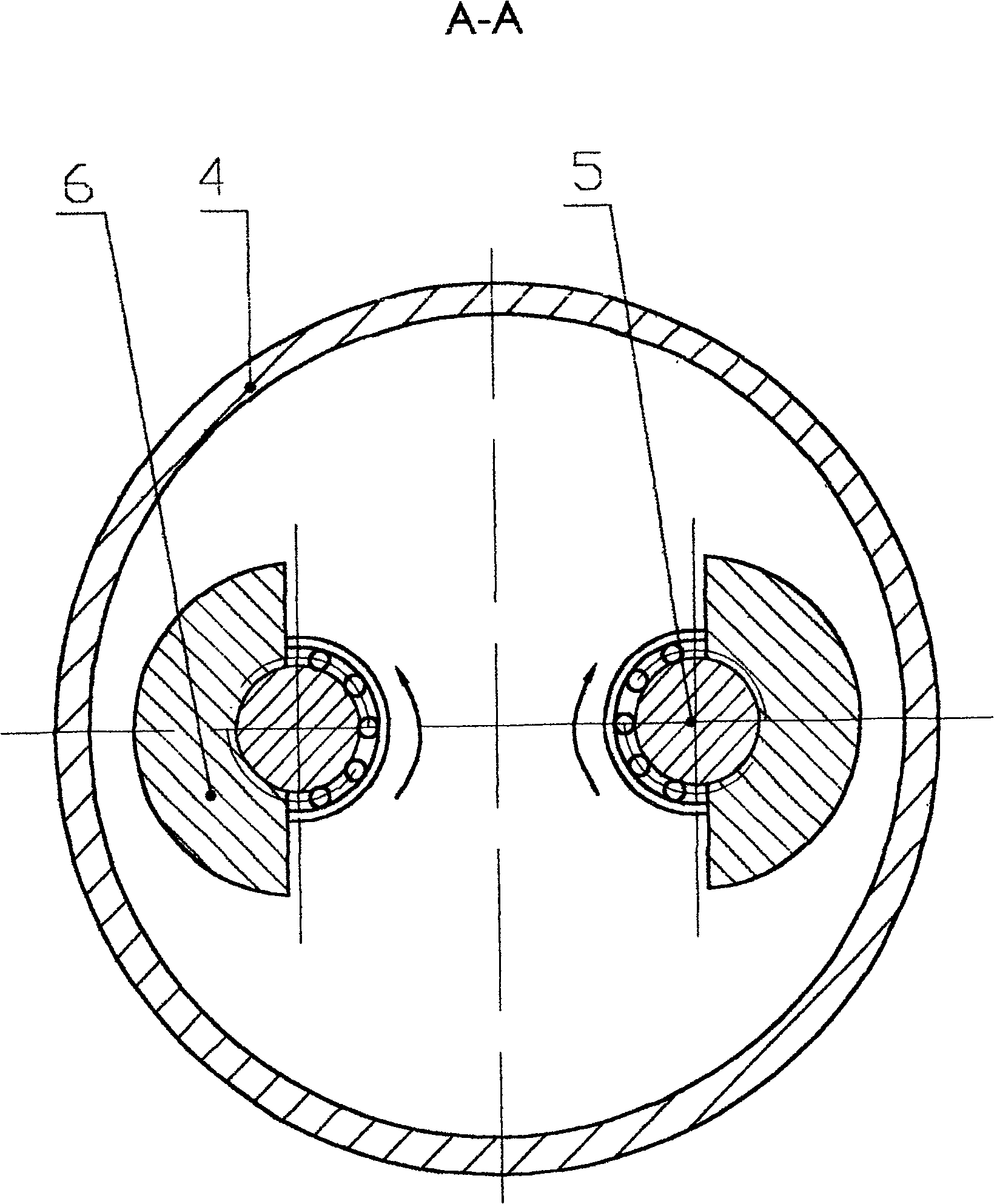

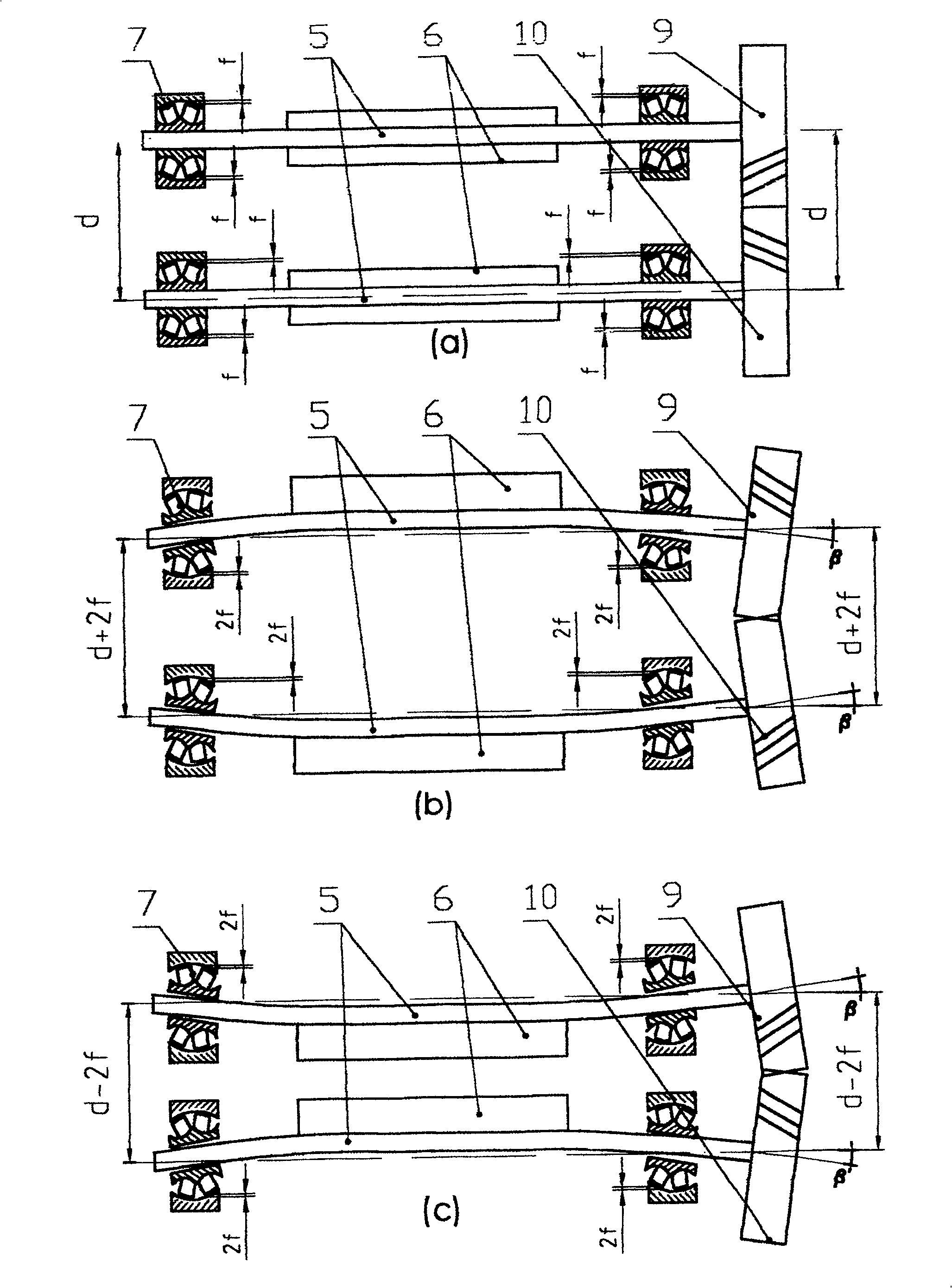

[0031] First, a brief introduction to the prior art is made (see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 ). Typical structural schematic diagram ( figure 1 and figure 2 ), the travel motor 1 is installed on the frame 17, the travel motor 1 is connected with the vibrating wheel body 3 through the shock absorber 2, and the vibration output bearing 15 is assembled on the two ends of the vibration exciter housing 4, and the vibration output bearing 15 is installed in the vibration output bearing seat 16, and the vibration output bearing seat 16 is assembled on the two ends of the inner hole of the vibration wheel body 3. 17 connected, two eccentric shafts 5 with eccentric blocks 6 installed in parallel in the horizontal direction through the vibration bearing 7 and the vibration bearing seat 8 are relatively installed in the exciter housing 4. The so-called relative installation refers to two fixed shafts. The eccentric shaft 5 with the eccentric block 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com