Method of greenly preparing rare-earth potassium orthophosphate nano/micro crystal

A technology of orthophosphate and microcrystals, applied in the field of hydrothermal synthesis, can solve the problems of complex process, high production cost, unfavorable environmental protection and rational application of resources, and achieve the effect of simple process, convenient operation and convenient industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of lanthanum phosphate nanowires or nanorods

[0032] (1) Add 2.0×10 -4 mol of La 2 o 3, phosphorus pentoxide or phosphoric acid, La 2 o 3 The molar ratio is 1:1, after adding deionized water to make the filling degree of the reactor reach 60-80%, the reactor is sealed;

[0033] (2) Then transfer the reaction kettle to a temperature-controlled furnace, and control the reaction temperature to be 100°C, 140°C, 160°C, and 250°C at a heating rate of 10°C / min, and heat at this temperature for 24, 24, and 24, respectively. 6, 18, 48, 1 hour.

[0034] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0035] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

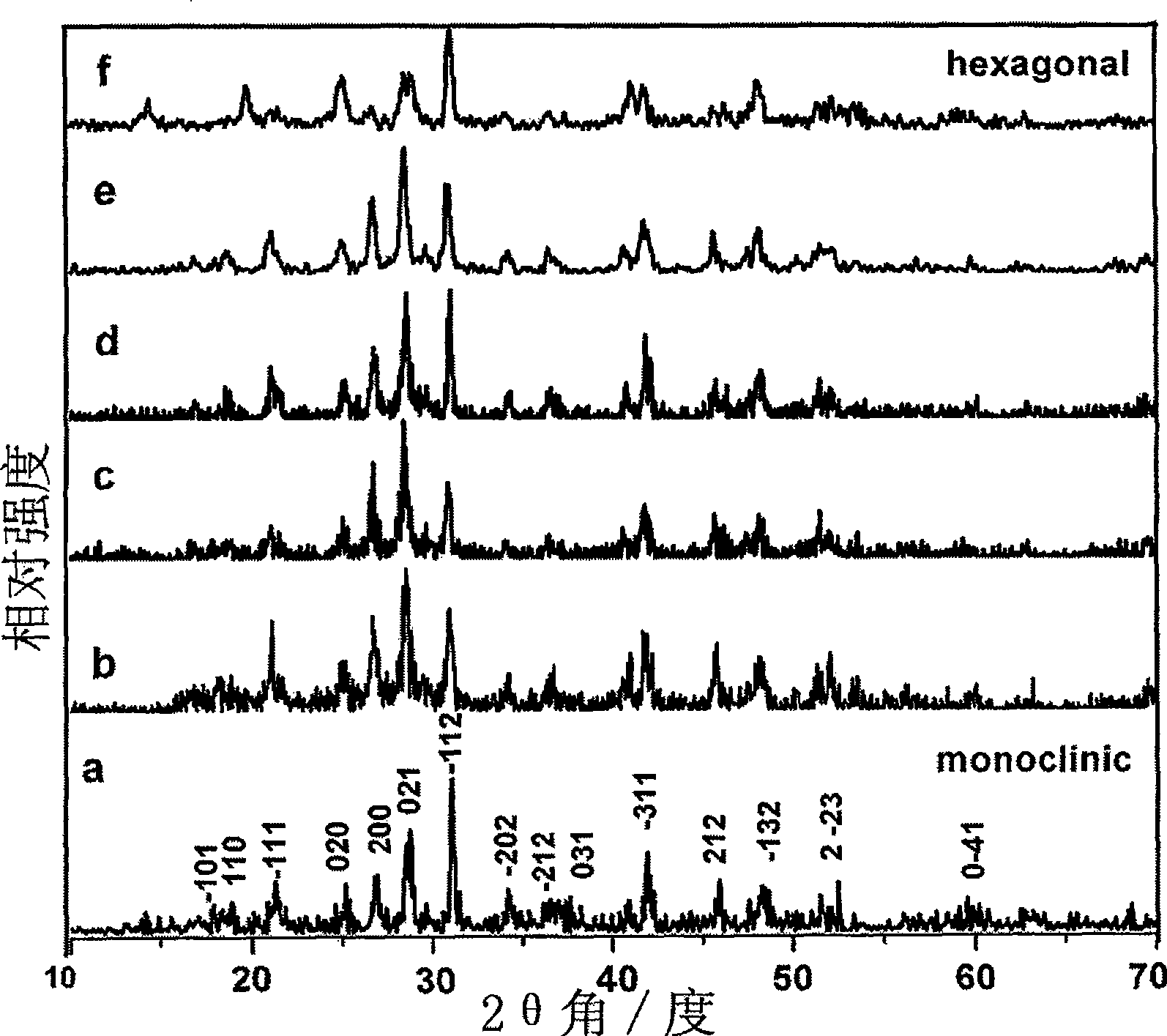

[0036] figure 1 The X-ray powder diffraction patterns of the products obtained under di...

Embodiment 2

[0037] Embodiment 2: Preparation of lanthanum phosphate nanorods or nanoparticles

[0038] (1) Add 2.0×10 -4 mol of La 2 o 3 , phosphorus pentoxide or phosphoric acid, La 2 o 3 The molar ratios are 50:1, 100:1 and 200:1 respectively, add deionized water to make the reactor fill degree reach, after 50-60%, seal the reactor;

[0039] (2) Then, the reaction kettle was transferred to a temperature-controlled furnace, and the reaction temperature was controlled to be 160° C. at a heating rate of 8.5° C. / minute, and heated at this temperature for 24 hours.

[0040] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0041] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

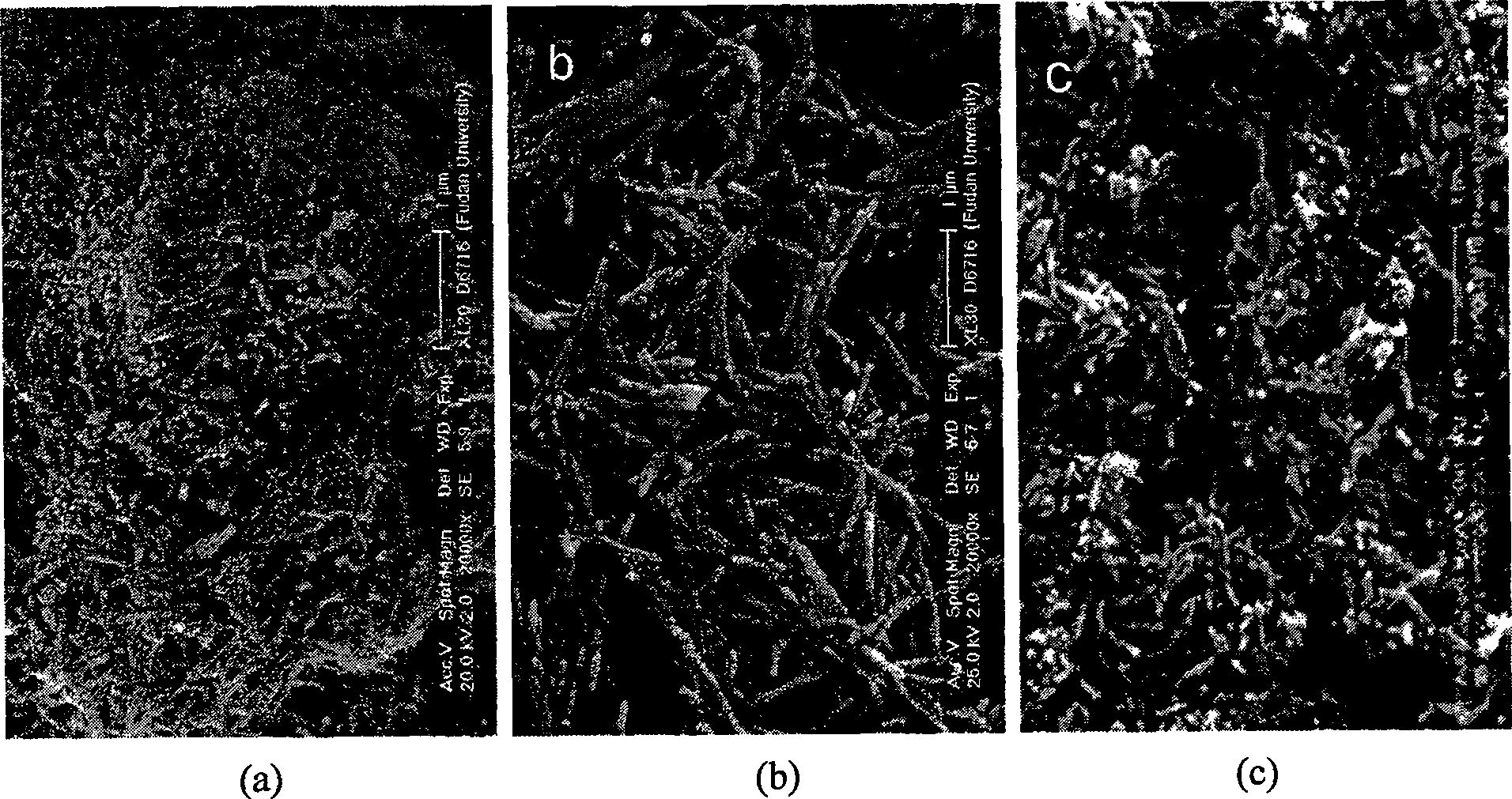

[0042] from image 3 Visible a), the LaPO obtained when the molar ratio P / La=50 4 The scanning electron m...

Embodiment 3

[0043] Embodiment 3: prepare Nd, Sm, Gd phosphate nanomaterial

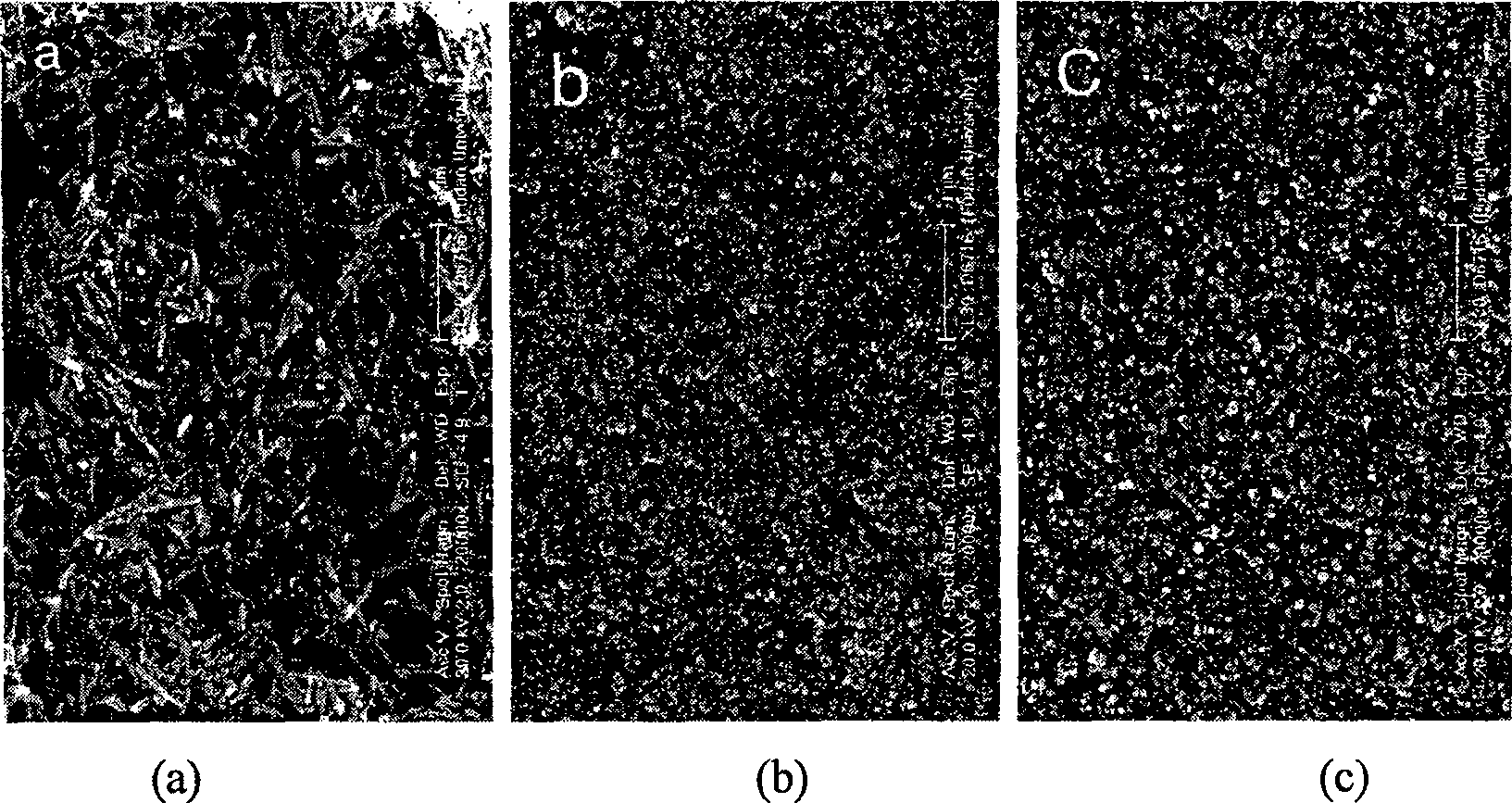

[0044] Take 2.0×10 respectively -4 mol of Nd 2 o 3 , Sm 2 o 3 , Gd 2 o 3 , and 50 microliters of phosphoric acid solution (85%) are raw materials, adding deionized water makes the degree of filling of the reactor reach 60-80%, the control reaction temperature is respectively 140 ° C, 250 ° C, and the reaction time is 24 hours. Other operating processes and Example 1 is the same. Figure 4 The SEM photo of the resulting part of the product given in , shows that the product is a nano-scale particle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com