Transistor tube valve with force top pressing structure

A thyristor valve and thyristor technology, which is applied to electrical components, electro-solid devices, circuits, etc., can solve the problems of laborious installation and maintenance, high strength requirements of top-loading bolts, etc., to achieve simple structure, improve operation safety, and reduce strength requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

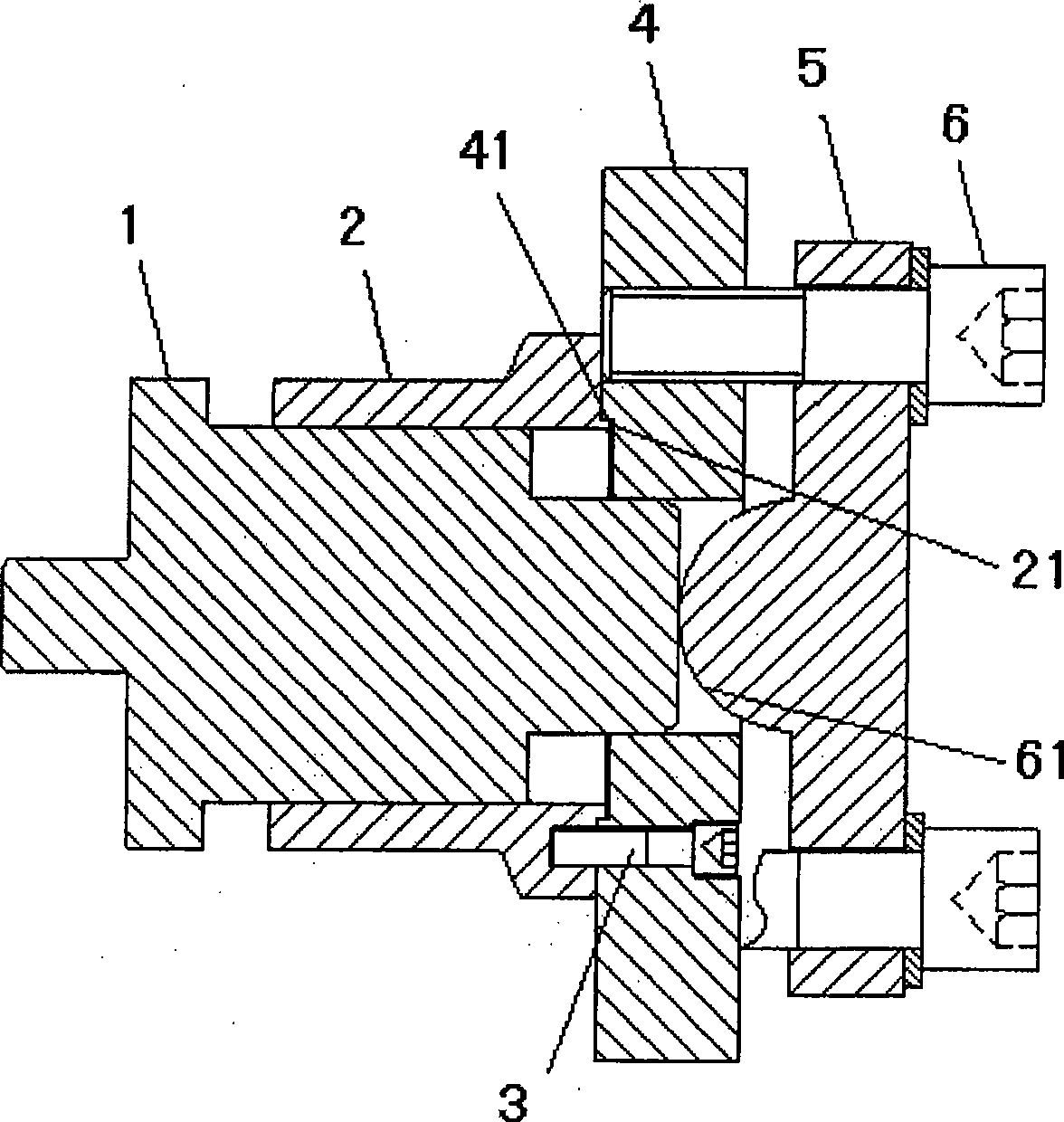

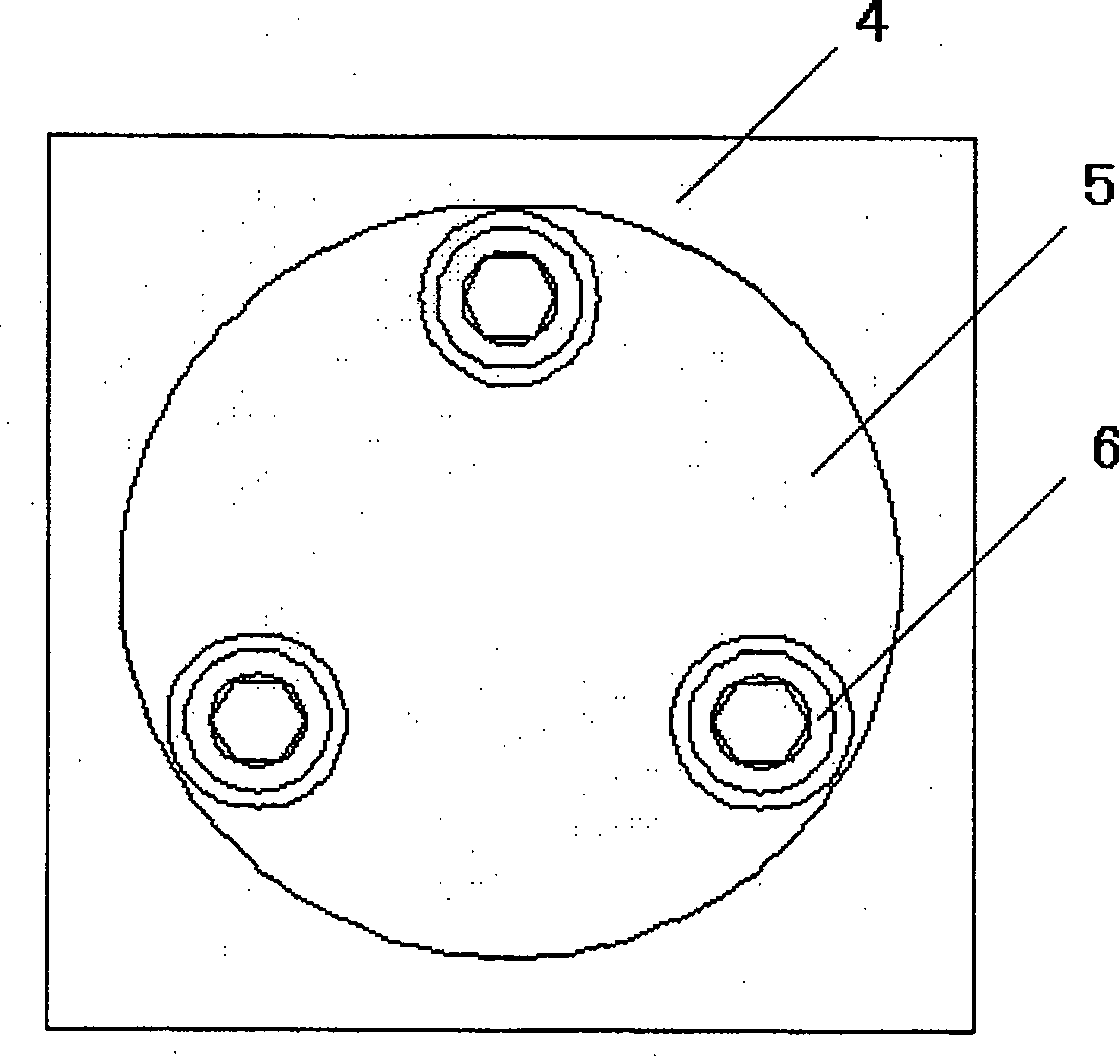

[0014] Such as figure 1 As shown, the present invention includes a pressing guide rod 1, and a guide sleeve 2 is set on the pressing guide rod 1. There is a clearance fit between the pressing guide rod 1 and the guide sleeve 2, so that the pressing guide rod 1 can be guided along the The sleeve 2 slides axially and keeps them concentric. One end of the guide sleeve 2 is connected to the flange 4 through the screw 3, and the guide sleeve 2 and the flange 4 are positioned through the seams 21 and 41 and also kept concentric. The flange plate 4 is connected to a pressure plate 5 through three pressure bolts 6. The end of the pressure plate 5 in contact with the pressure guide rod 1 is a spherical head 61. The pressure plate 5 is connected to the pressure plate 5 through three pressure bolts 6. On the flange 4, the spherical head 61 of the pressing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com