Engine mechanical pressurizing apparatus

A technology of supercharging and engines, which is applied in the direction of engine components, machines/engines, liquid fuel engines, etc. It can solve the problems of high friction between the outer end and the inner wall of the casing, large vibration of the supercharger, and poor scavenging effect. Achieve good supercharging effect, improve friction, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

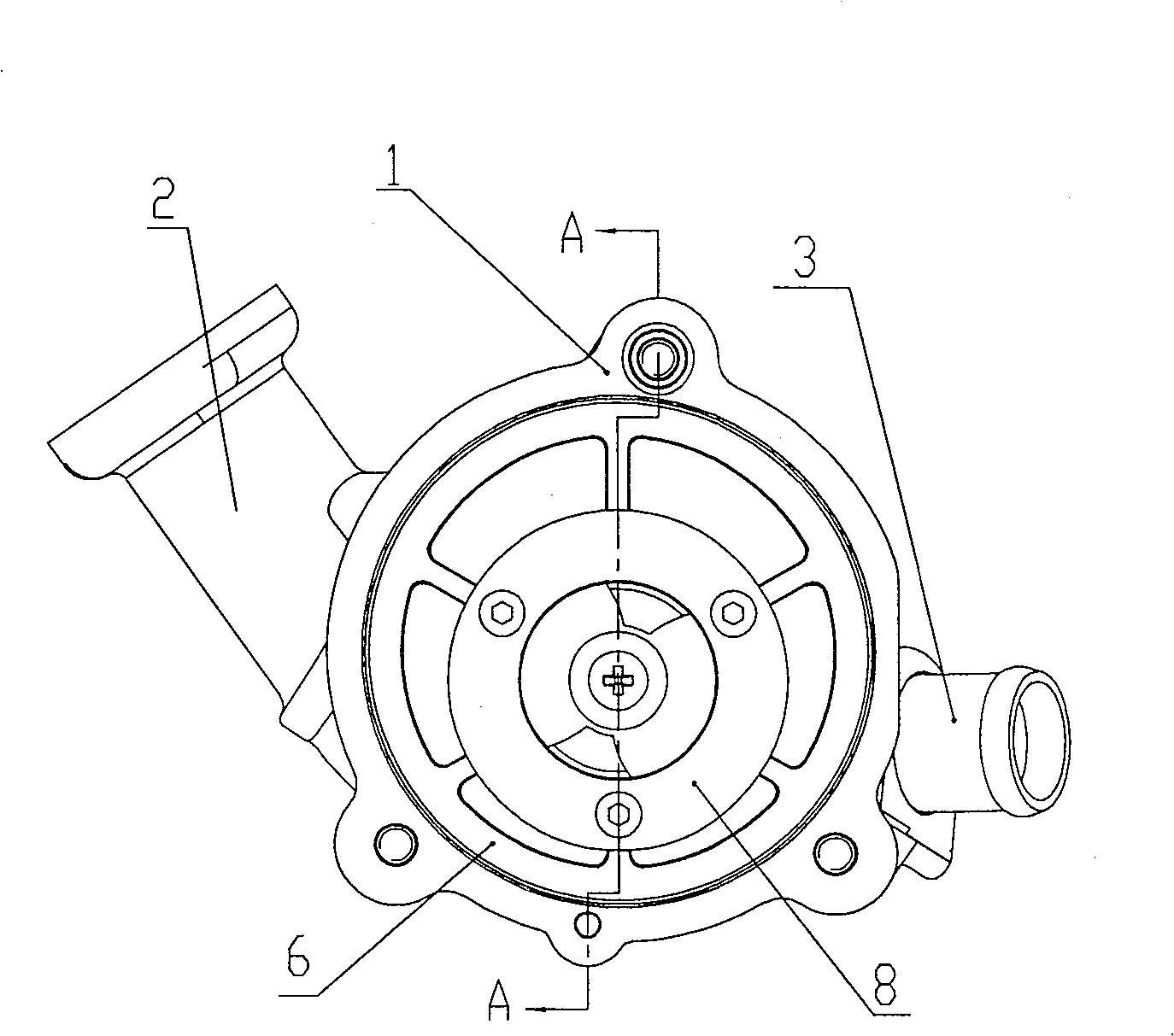

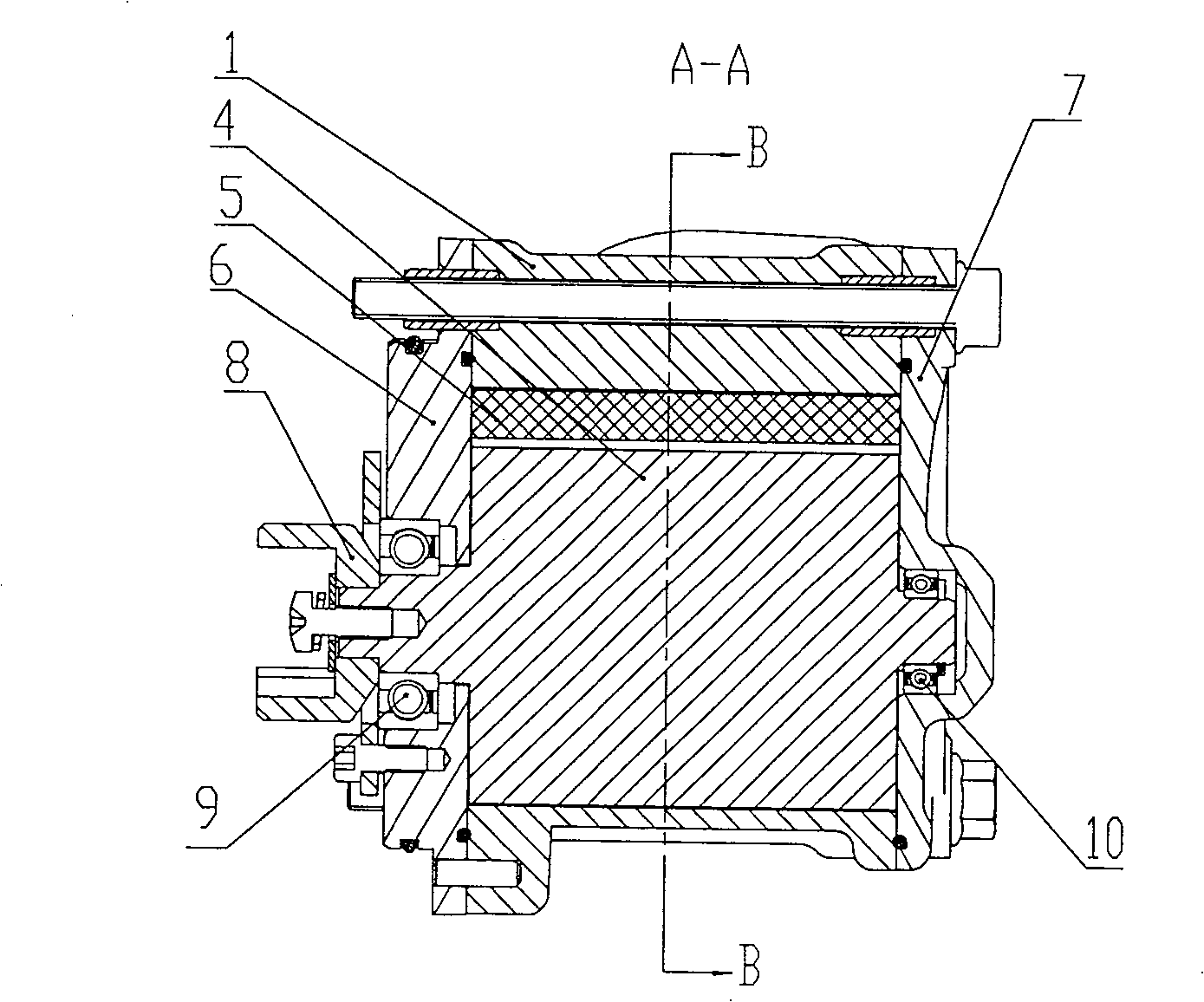

[0011] refer to figure 1 ,set up figure 1 What can be seen is the front part of the invention, the back side is the rear part, and the left and right directions refer to this accompanying drawing. Supercharger body 1 of the present invention consists of front shell 6 and rear shell 7 (see figure 2 ), the inner cavity formed by the shell is cylindrical, and the left and right ends of the supercharger body 1 are equipped with an intake pipe 2 and an exhaust pipe 3.

[0012] refer to figure 2 , The front shell 6 and the rear shell 7 of the supercharger body 1 are respectively provided with a bearing 9 and a bearing 10, and the rotor 10 is installed in the inner cavity of the supercharger, and both ends are supported by the bearing 9 and the bearing 10. There is a shaft coupling 8 at one end of the rotor 4 protruding from the front shell 6, and the shaft coupling 8 is connected with the rotating mechanism to provide power for the supercharging device.

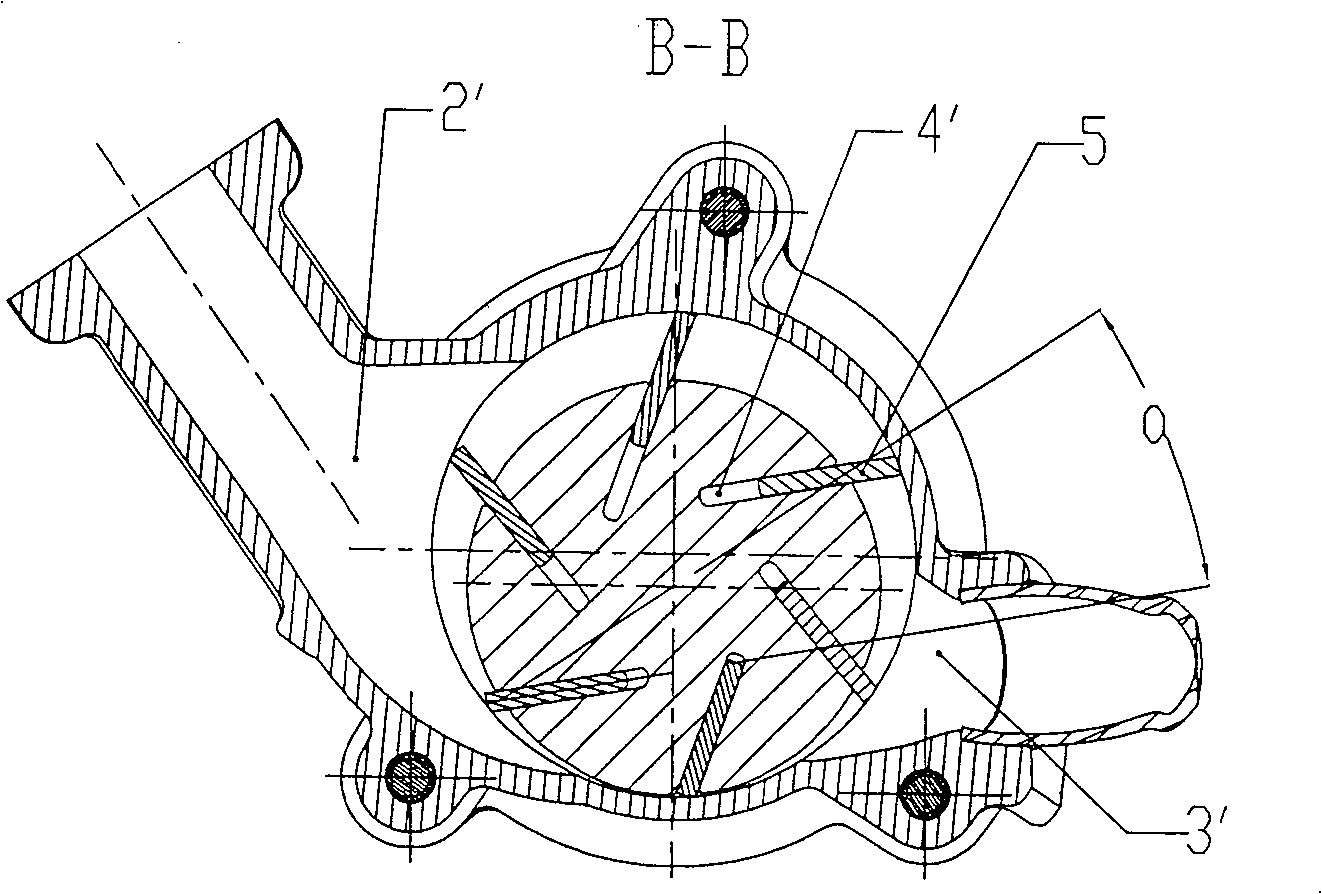

[0013] refer to ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com