Transformer framework

A transformer skeleton and frame technology, which is applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems that the temperature protection device cannot provide accurate and reliable temperature induction and the winding is not smooth, so as to achieve simplified structure and high temperature Preserve the accuracy and reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

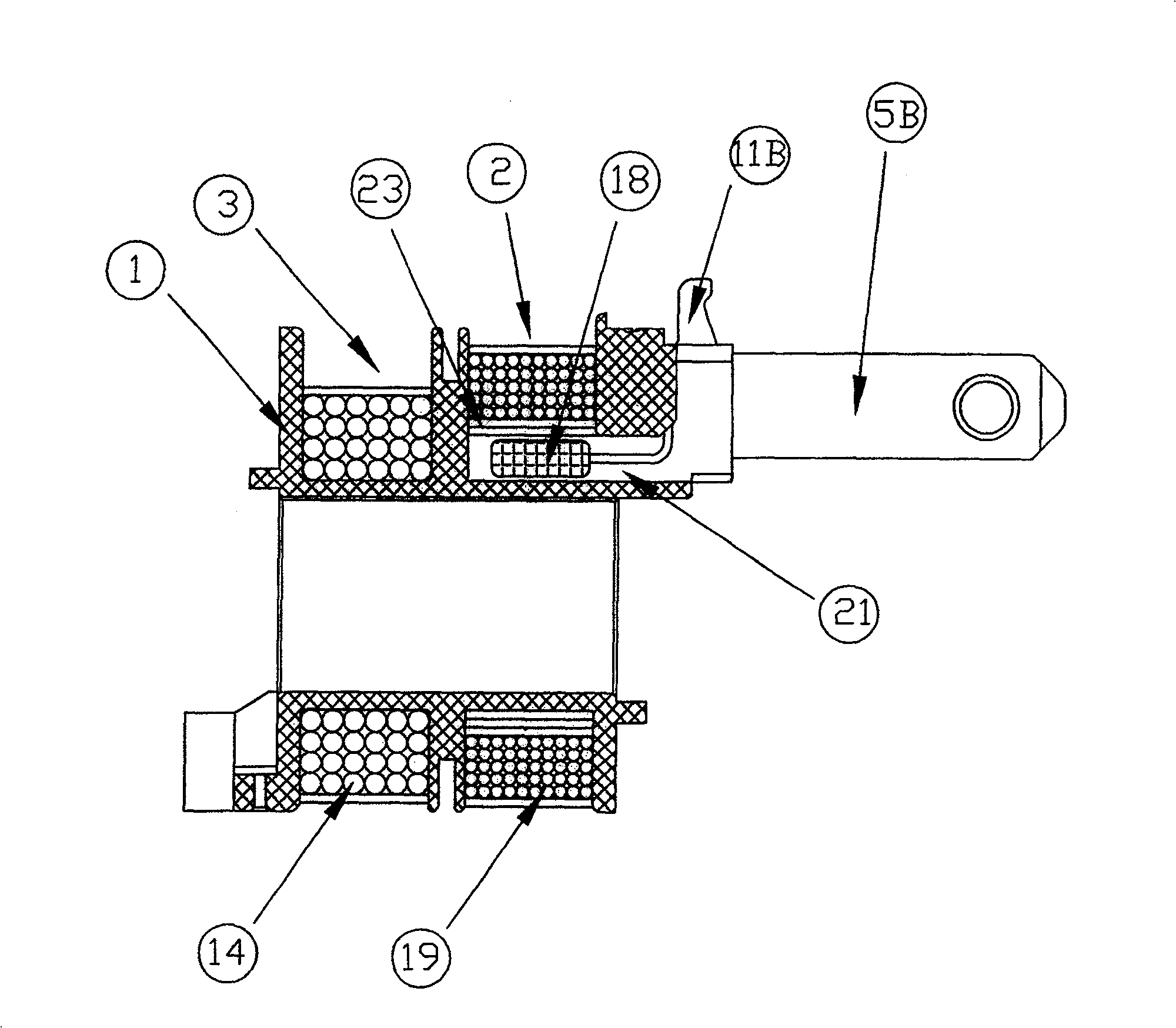

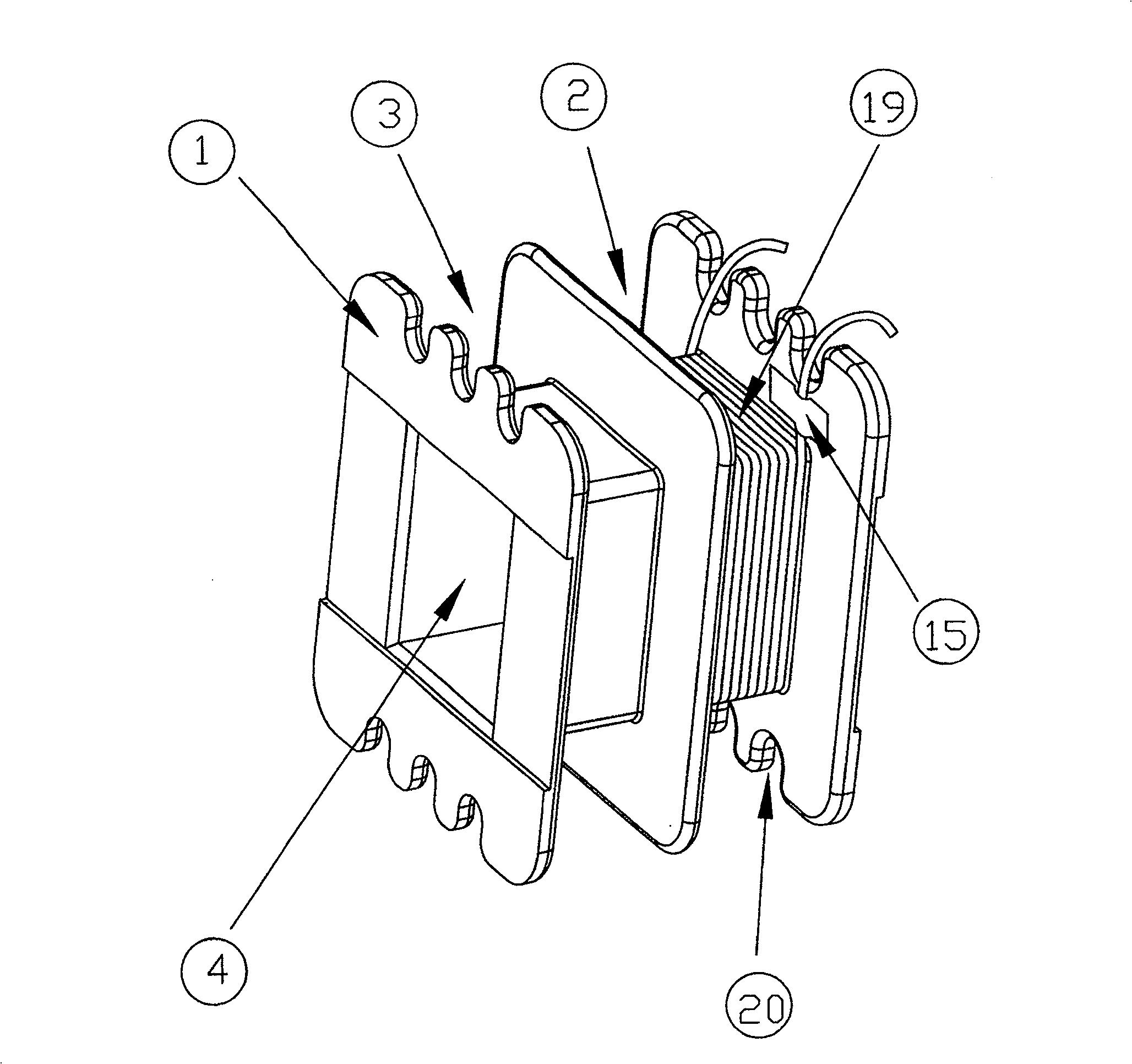

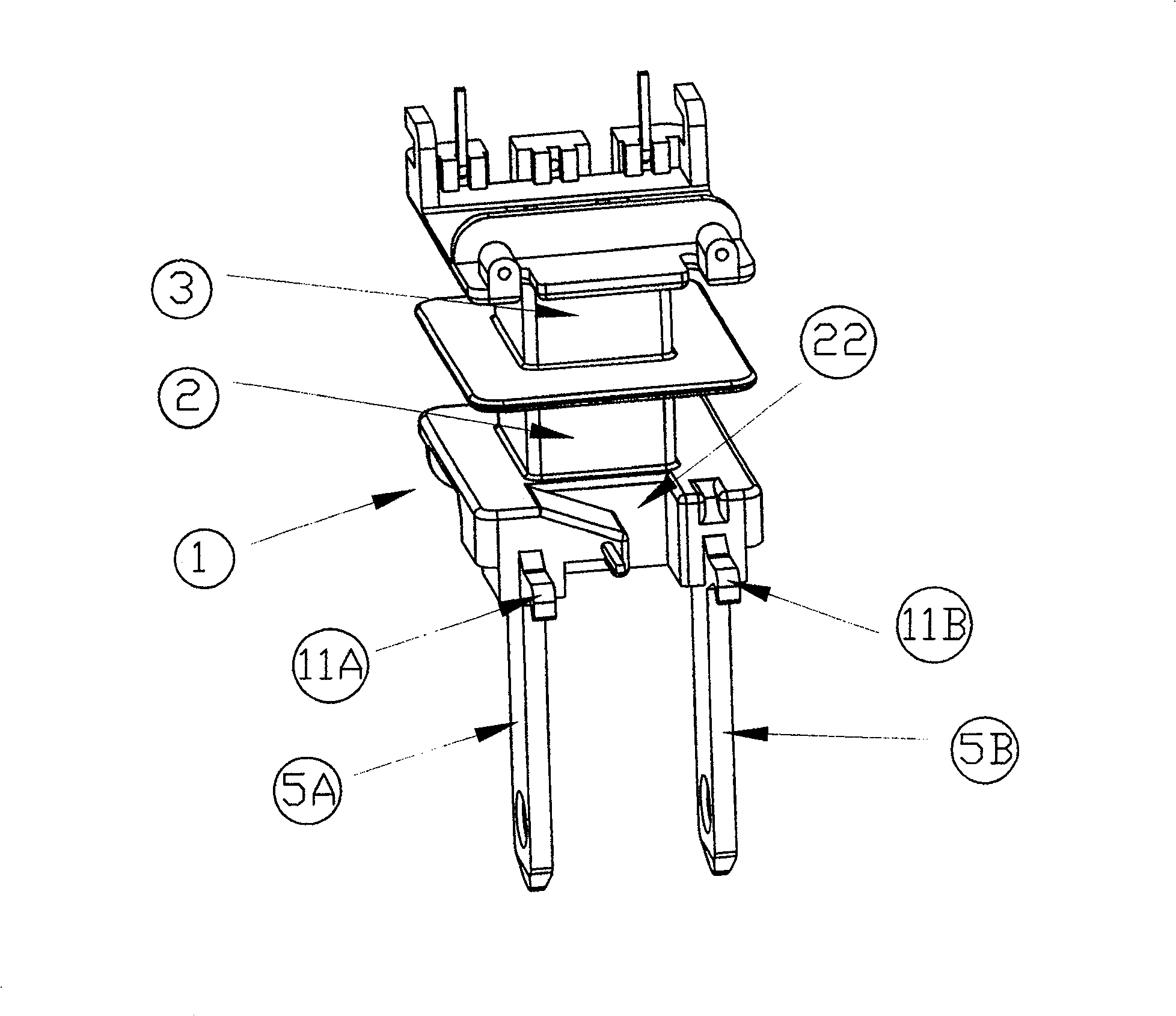

[0029] figure 1 , figure 2 as well as image 3 Both are structural diagrams of existing transformer skeletons.

[0030] Such as figure 1 As shown, in the prior art, a long slot 21 is cut horizontally along the bottom of the primary coil slot 2 of the transformer skeleton, and the temperature protection device 18 is placed in the long slot 21, and then the temperature protection device 18 is wrapped Cover with insulating tape 23, so that the temperature protection device 18 and the primary coil winding 19 can be separated. However, due to the heat insulation effect of the insulating tape 23 in this structure, it will be difficult for the temperature protection device 18 to sense the temperature of the transformer accurately and reliably, so it is easy to cause the temperature of the transformer to be too high and the temperature protection device 18 is caused by the insulating tape 23. The existence of such problems as not sensing the change of temperature in time, and thu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com