Preparation and application method of a cathodic electrophoretic coating additive with good edge coating effect

A cathodic electrophoretic coating and edge technology, which is applied in electrophoretic coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor corrosion resistance, poor compatibility, and poor stability of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of amino-epoxy resin

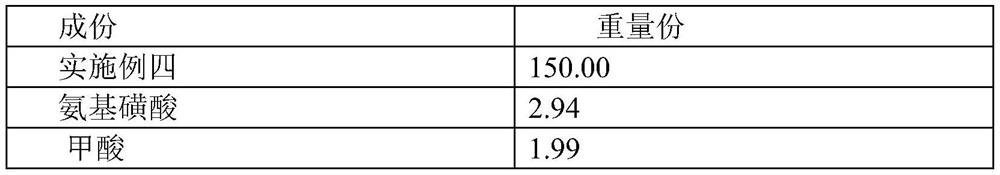

[0037] ingredients parts by weight (1) Methylethanolamine 58.86 (2) Polyetheramine 100.40 (3) BE-504(1) 976.00

[0038] Note (1): Epoxy resin, produced by Changchun Chemical Industry

[0039] Add the sequence (1) and (2) in the formula to the reactor, stir and heat up to 90°C, after the temperature reaches, add (3) in the formula, after adding all the ingredients, keep warm at 110-120°C for 1.5 hours, An amino-epoxy resin with a solids content of 100% and an amine equivalent weight of 882 was obtained.

Embodiment 2

[0041] Preparation of amino-epoxy resin

[0042] ingredients parts by weight (1) Methylethanolamine 39.53 (2) Dimethylaminopropylamine 9.82 (3) Polyetheramine 168.66 (4)CYD-014U(2) 370.00 (5) CYD-011 (2) 216.00

[0043] Note (2): Epoxy resin, produced by Yueyang Petrochemical

[0044] Add (1), (2), and (3) in the formula to the reactor, stir and heat up to 80-85°C; after the temperature reaches, add (4) and (5) in batches; Heat preservation at 110-120°C for 2 hours to obtain an amino-epoxy resin with a solid content of 100% and an amine equivalent of 908.

Embodiment 3

[0046] Preparation of modified epoxy resin

[0047] ingredients parts by weight Embodiment one 1135.26 E-10(3) 373.10

[0048] Note (3): Glycidyl ether of tertiary carbonic acid, produced by DOW

[0049] On the basis of Example 1, the formula amount of E-10 was added, the temperature was raised to 130-140° C., and kept for 4 hours to obtain a modified amino-epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com