Pull-type soil shifter smoothing technique for soft foundation field and pull-type soil shifter

A soft foundation and bulldozer technology, applied in mechanically driven excavators/dredgers, etc., to achieve the effects of high cost performance, fast work efficiency, and simple and feasible equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

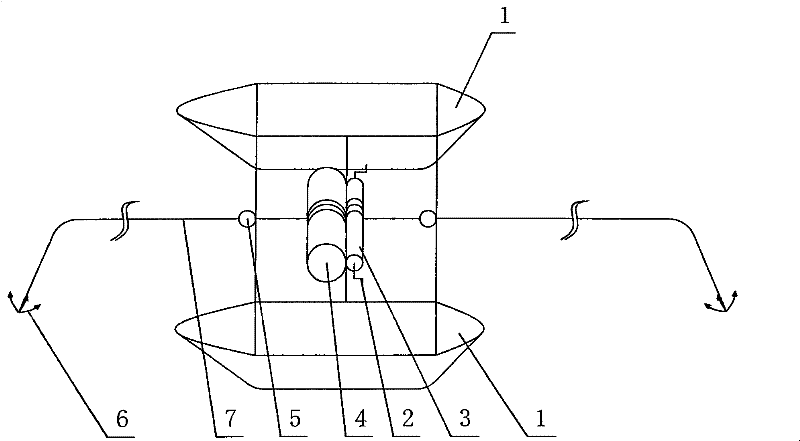

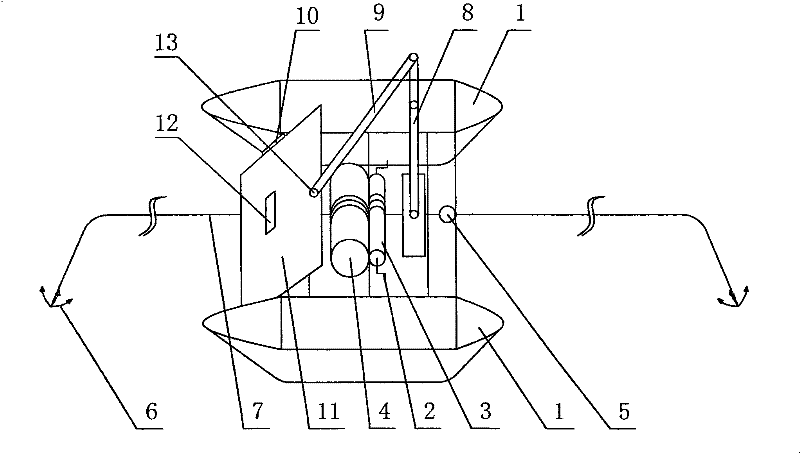

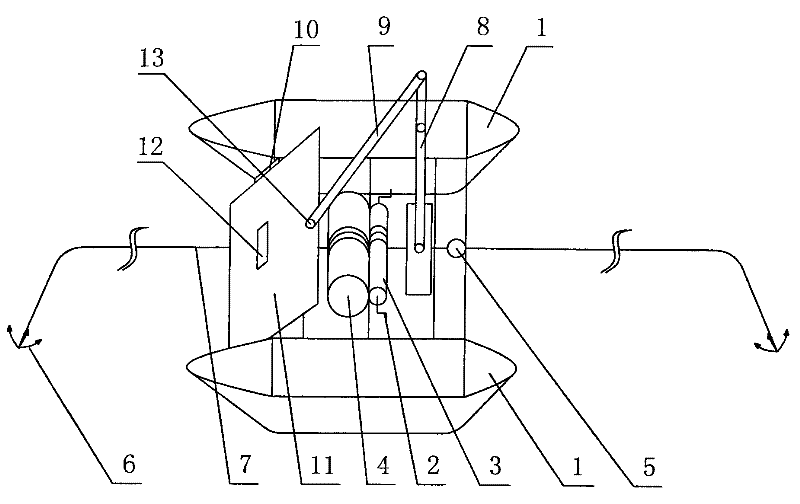

[0030] The invention relates to a "traction-type bulldozer" leveling method for weak foundation sites and the traction-type bulldozer. The method is to use a catamaran pontoon 1 to cooperate with a small lifting crane, and the small lifting crane cooperates with a bulldozing plate to make a traction-type bulldozer. Bulldozers, use traction bulldozers to carry out bulldozing and leveling construction on weak sites and newly blown pad sites.

[0031] The manufacturing method of the catamaran pontoon is as follows:

[0032] see figure 1 First, two monohulls are made, and the two monohulls are arranged parallel to the left and right, and then according to the width of the bulldozer, the assembly distance between the two monohulls is determined, generally 1.5m to 2.0m wide. The two monohulls are connected with angle steel or other materials to form a catamaran pontoon. Finally, a winch 2 is installed on the made catamaran pontoon, which is installed in the middle of the catamaran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com