Tool quick-switching interface for telecontrolling welding robot

A welding robot and fast conversion technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problem of unsuitable remote control welding robot application, achieve the requirements of rapid tool replacement and welding, and facilitate automatic clamping and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

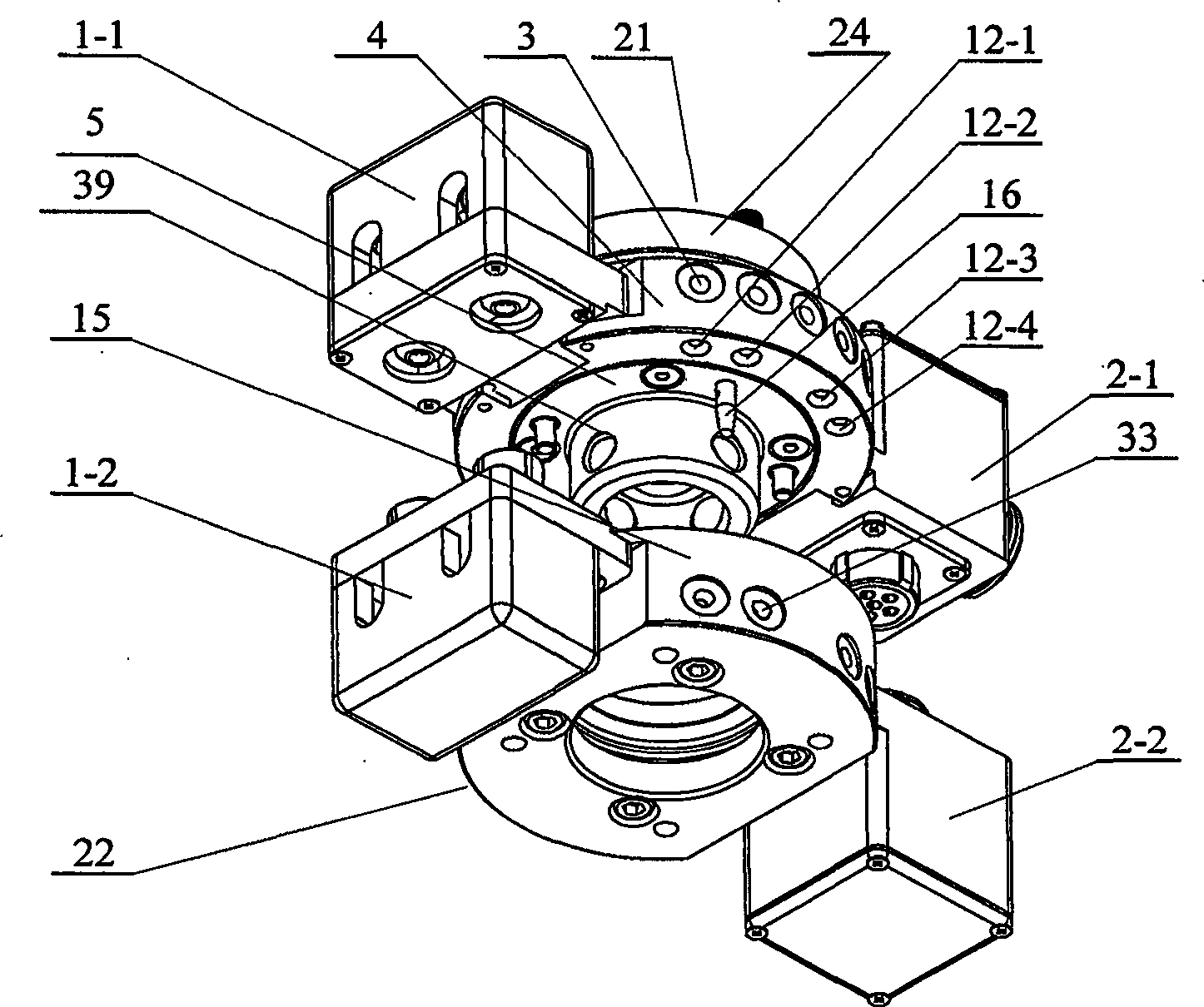

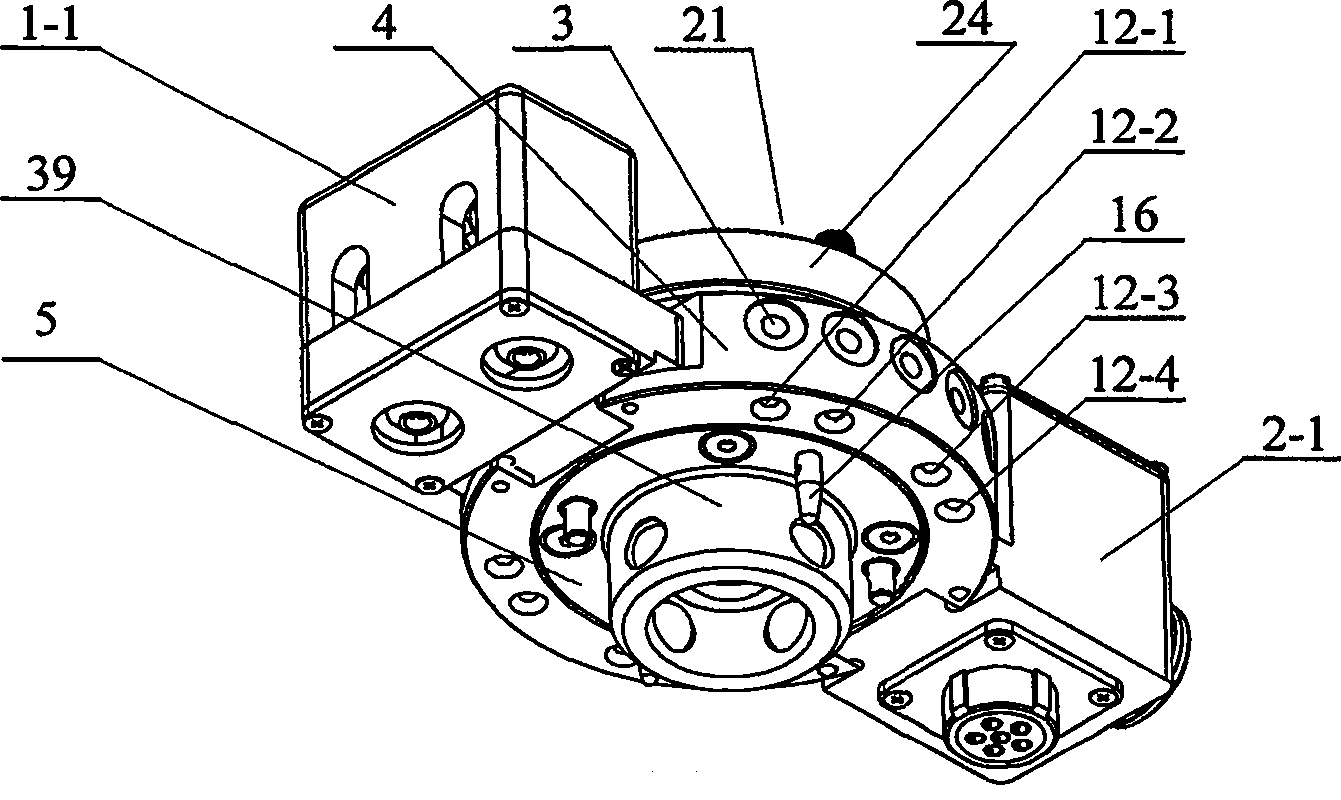

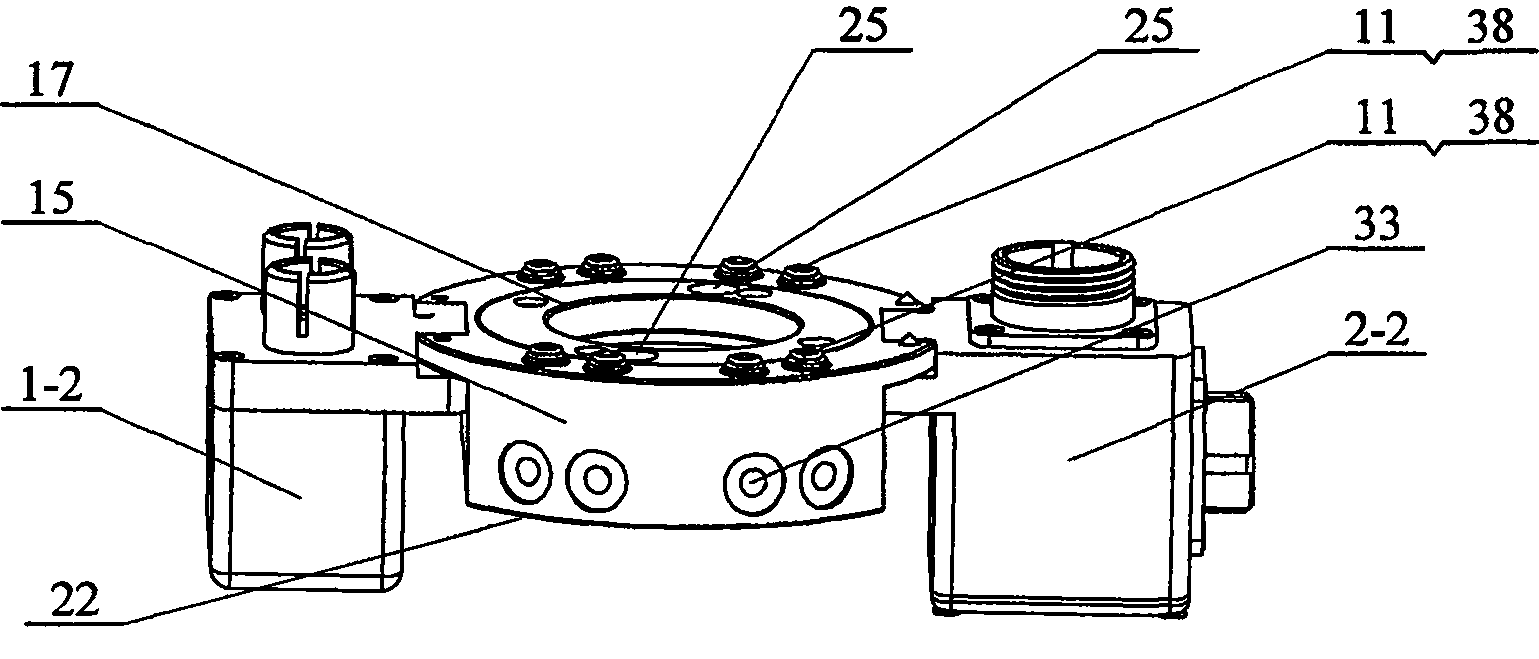

[0007] Specific implementation mode one: (see Figure 1 to Figure 5 ) This embodiment consists of a robot-side interface module 21 and a tool-side interface module 22. The robot-side interface module 21 consists of a first electrical plug 1-1, a second electrical plug 2-1, a main port body 4, and a cylinder lower end cover 5. Composed of bracket 39, piston rod 7, cylinder reverse stroke buffer rubber pad 8, cam 9, piston 10, positioning pin 16, cylinder upper cover 23 and connection plate 24, one end of the main port body 4 is provided with a first ear eaves 31. The other end of the main port body 4 is provided with a second ear eaves 34, the first electrical plug 1-1 is connected to the second ear eaves 34, the second electrical plug 2-1 is connected to the first ear eaves 31 The inner cavity of the main port body 4 is a cylinder 36, the bracket 39 is arranged on the lower side of the cylinder lower end cover 5, the bracket 39 is connected with the cylinder lower end cover 5,...

specific Embodiment approach 2

[0008] Embodiment 2: In this embodiment, the sealing gasket 38 is made of polytetrafluoroethylene. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: In this embodiment, the main port body 4 , the tool port body 15 and the piston 10 are made of hard aluminum alloy. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com