Coaxial spinning method for preparing hollow molecular sieve fiber possessing grade structure

A spinning technology and a technology of hierarchical structure, applied in the field of preparation of molecular sieve fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

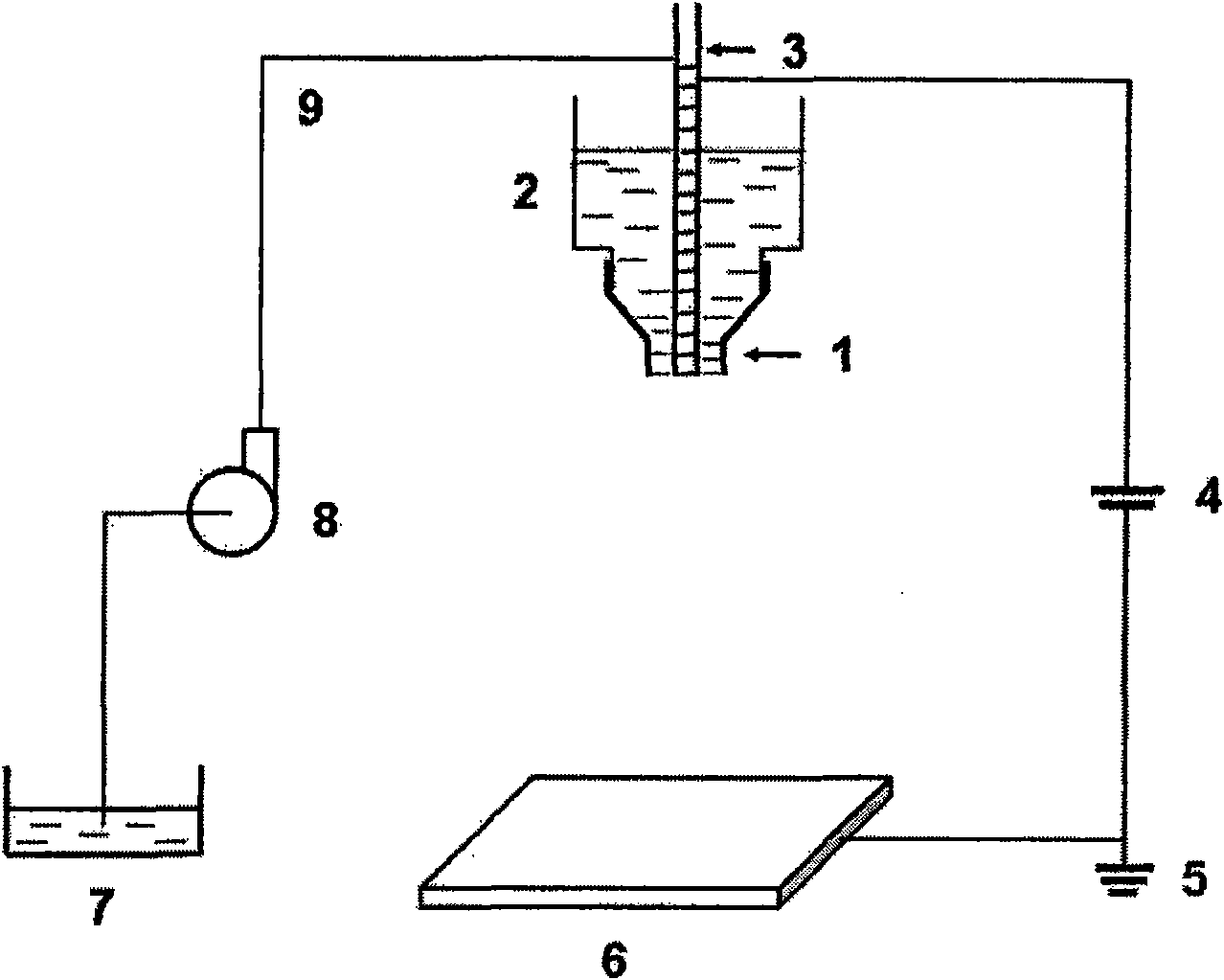

Method used

Image

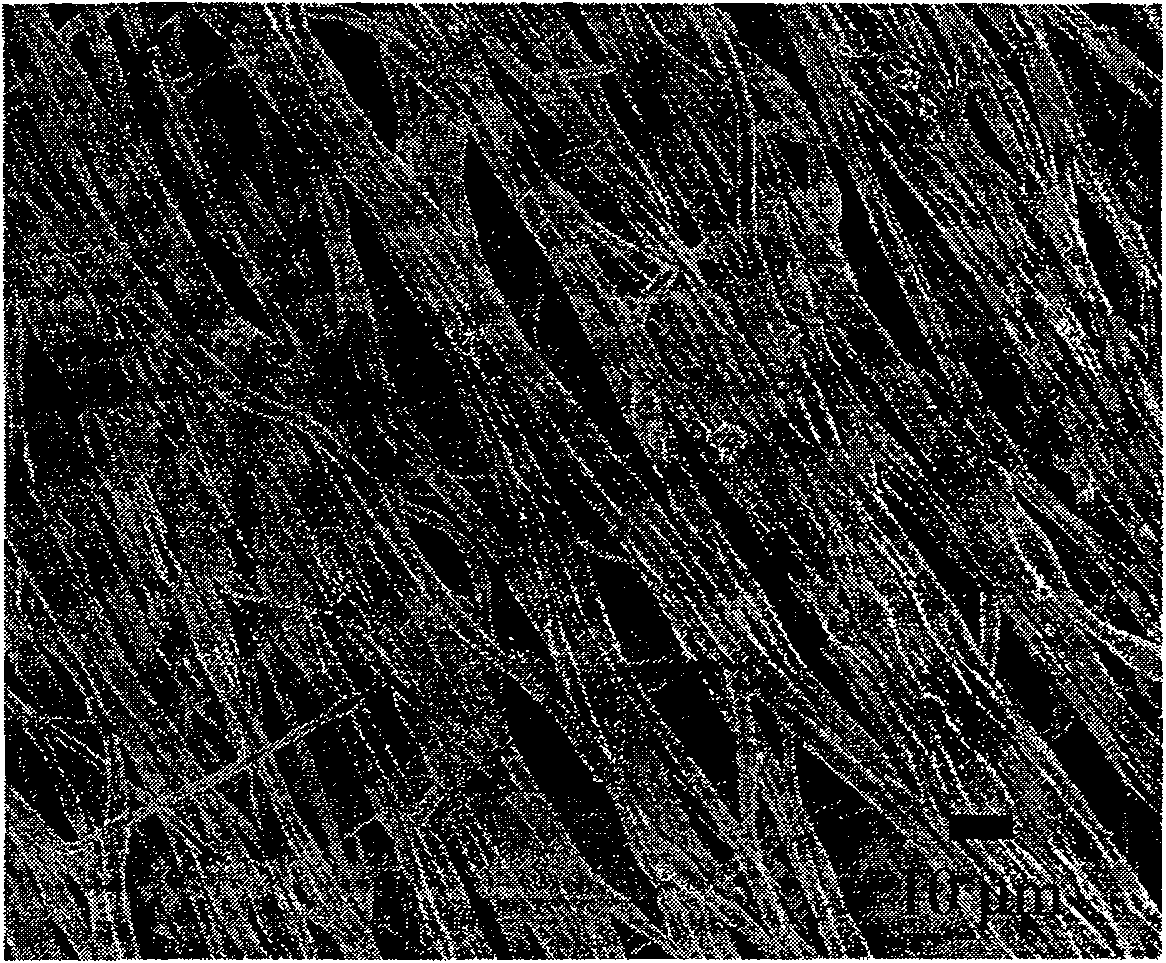

Examples

Embodiment 1

[0052] The ethanol solution of molecular sieve nanoparticles silicalite-1 / polyvinylpyrrolidone (PVP) is used as the outer fluid, and liquid paraffin is used as the inner fluid:

[0053] The synthesis of Silicalite-1 (skeleton type is MFI) nanoparticles was described in the literature Microporous Mesoporous Mater., 1999, 31, 141-150. The synthesized particles are repeatedly centrifuged, dispersed and washed until the pH value is between 7 and 9, the particle diameter is about 100nm, and the pore size of the molecular sieve is 0.55nm.

[0054] Add 0.8 g of washed molecular sieve nanoparticles to 8 g of absolute ethanol, and after 5 hours of ultrasonic dispersion, stir with a magnetic stirrer for 24 hours, then add 1.0 g of polyvinylpyrrolidone (PVP), and continue stirring for 4 hours to obtain a uniform Take 2mL of this solution and put it into the plastic outer nozzle of the electrospinning equipment as the outer fluid; use liquid paraffin as the inner fluid, and send the inner...

Embodiment 2

[0058] The ethanol solution of molecular sieve nanoparticles silicalite-1 / polyvinylpyrrolidone (PVP) is used as the outer fluid, and liquid paraffin is used as the inner fluid:

[0059] The synthesis of Silicalite-1 (skeleton type is MFI) nanoparticles was described in the literature Microporous Mesoporous Mater.1999, 31, 141-150. The synthesized particles are repeatedly centrifuged, dispersed and washed until the pH value is between 7 and 9, the particle diameter is about 100nm, and the pore size of the molecular sieve is 0.55nm.

[0060] Add 0.8 g of washed molecular sieve nanoparticles to 8 g of absolute ethanol, and after 5 hours of ultrasonic dispersion, stir with a magnetic stirrer for 24 hours, then add 1.0 g of polyvinylpyrrolidone (PVP), and continue stirring for 4 hours to obtain a uniform Take 2mL of this solution and put it into the plastic outer spray tube as the outer fluid. With liquid paraffin as the internal fluid, the internal fluid is sent to the inner spra...

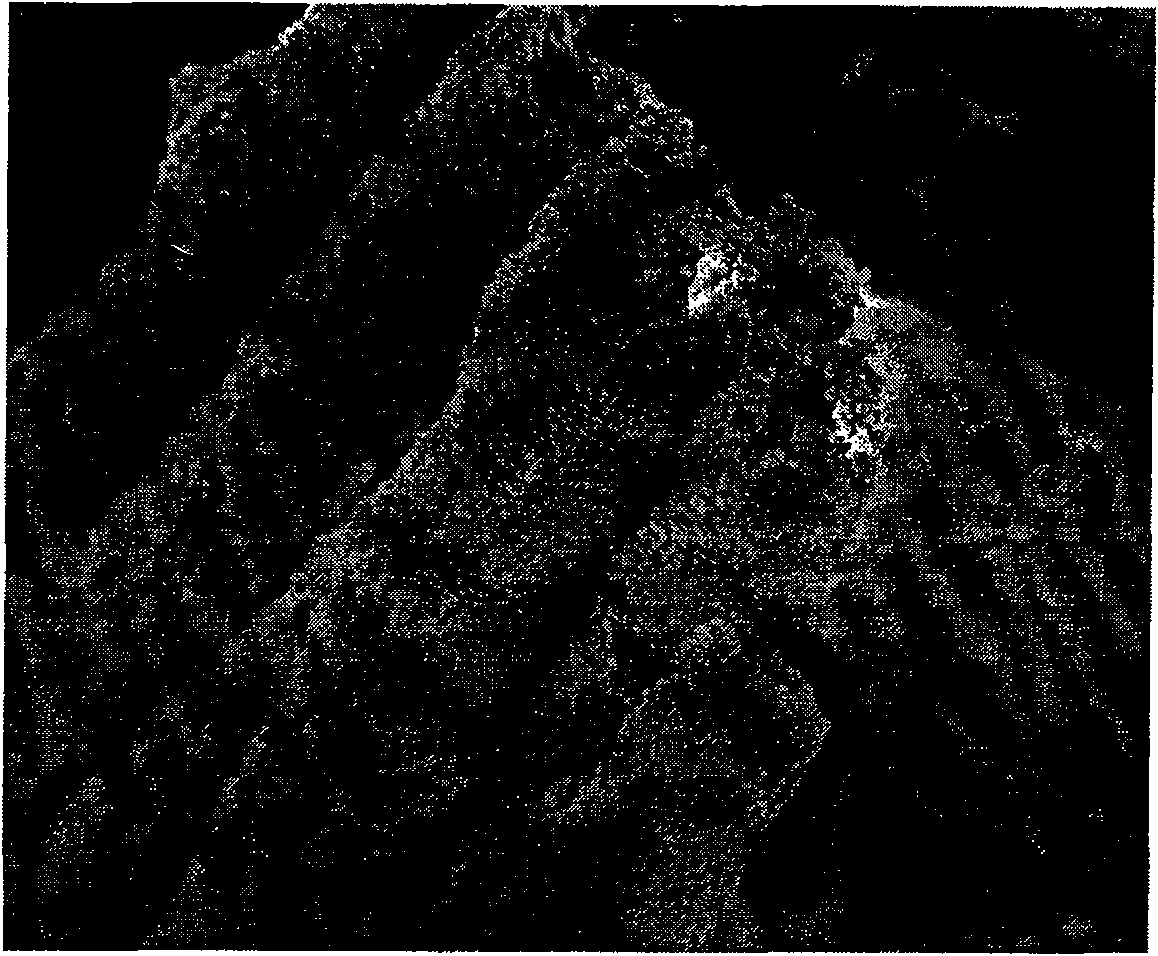

Embodiment 3

[0064] The ethanol solution of molecular sieve nanoparticles silicalite-1 / polyvinylpyrrolidone (PVP) is used as the outer fluid, and liquid paraffin is used as the inner fluid:

[0065] The synthesis of Silicalite-1 (skeleton type is MFI) nanoparticles was described in the literature Microporous Mesoporous Mater., 1999, 31, 141-150. The synthesized particles are repeatedly centrifuged, dispersed and washed until the pH value is between 7 and 9, the particle diameter is about 100nm, and the pore size of the molecular sieve is 0.55nm.

[0066] Add 0.8 g of washed molecular sieve nanoparticles to 8 g of absolute ethanol, and after 5 hours of ultrasonic dispersion, stir with a magnetic stirrer for 24 hours, then add 1.0 g of polyvinylpyrrolidone (PVP), and continue stirring for 4 hours to obtain a uniform Take 2mL of this solution and put it into the plastic outer spray tube as the outer fluid. With liquid paraffin as the internal fluid, the internal fluid is sent to the inner sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com