A kind of preparation method of integrated small diameter artificial vascular stent

A technology for artificial blood vessels and vascular stents, applied in stents, textiles, papermaking, filament/thread forming, etc., can solve problems such as vascular intimal hyperplasia and easy formation of thrombus, and achieve good biocompatibility, low cost, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Step 1, prepare spinning solution

[0073] At room temperature, the silk fibroin and the sulfated silk fibroin were blended and dissolved in hexafluoroisopropanol, dissolved and stirred by a constant temperature magnetic stirrer until the solution was transparent, and a polymer A solution with a mass fraction of 7% was obtained; The lactone was dissolved in chloroform / N,N-dimethylformamide (7:3), dissolved and stirred by a constant temperature magnetic stirrer until the solution was transparent, and a polymer B solution with a mass fraction of 10% was obtained.

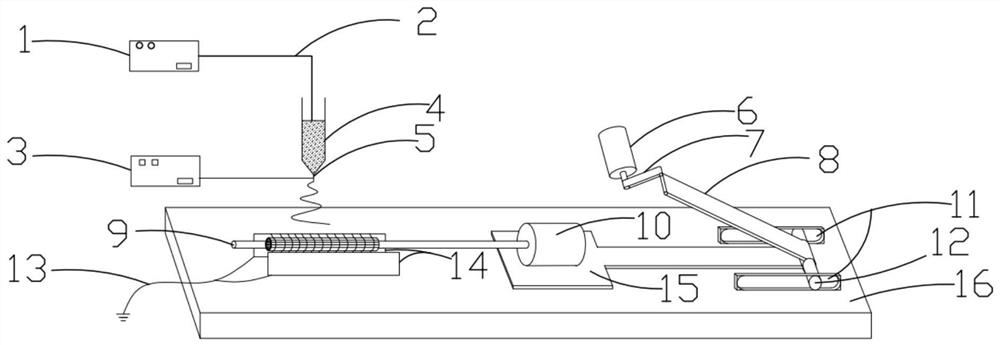

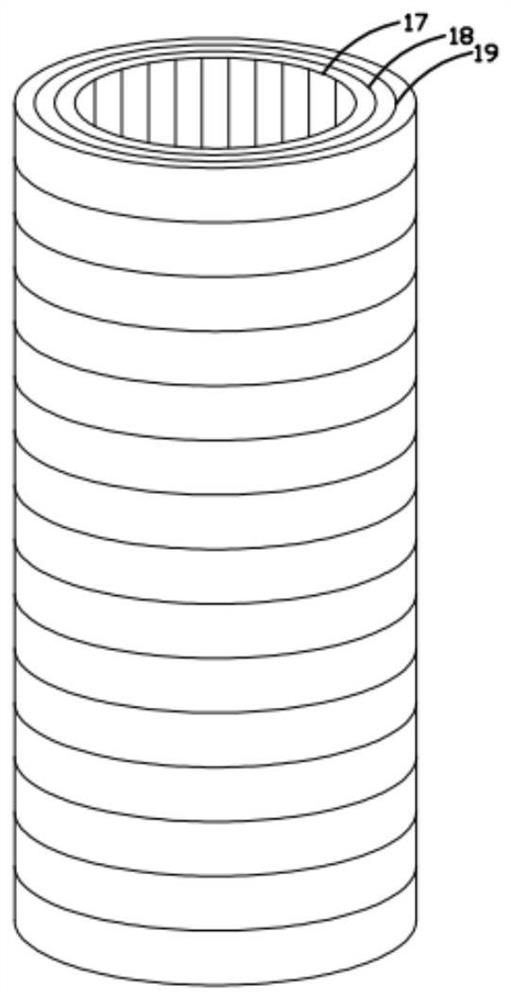

[0074] Step 2, preparation of vascular inner layer fibrous membrane

[0075] Under the environmental conditions of a temperature of 20° C. and a relative humidity of 45%, the prepared solution A was added to the syringe, and the distance between the two receiving plates was set at 3 cm. Apply a layer of lubricant (PEG) on the receiving roller before spinning, turn on the DC high voltage generator, adjust the s...

Embodiment 2

[0084] Step 1, prepare spinning solution

[0085] At room temperature, dissolve polyglycolic acid in hexafluoroisopropanol, pass through a constant temperature magnetic stirrer, dissolve and stir until the solution is transparent, and obtain a polymer A solution with a mass fraction of 8%; dissolve polyurethane in dichloromethane, pass through a constant temperature magnetic force Stirrer, dissolve and stir until the solution is transparent to obtain a polymer B solution with a mass fraction of 11%.

[0086] Step 2, preparation of vascular inner layer fibrous membrane

[0087] Under the environmental conditions of a temperature of 22° C. and a relative humidity of 55%, the prepared solution A was added to the syringe, and the distance between the two receiving plates was set at 3.5 cm. Apply a layer of lubricant (PEG) on the receiving roll before spinning, turn on the DC high voltage generator, adjust the spinning voltage to 20kV, adjust the spinning distance to 150mm, and co...

Embodiment 3

[0096] Step 1, prepare spinning solution

[0097] At room temperature, chitosan and collagen are blended and dissolved in trifluoroacetic acid, and dissolved and stirred until the solution is transparent by a constant temperature magnetic stirrer to obtain a polymer A solution with a mass fraction of 9%; ester) was dissolved in acetone, passed through a constant temperature magnetic stirrer, dissolved and stirred until the solution was transparent, and a polymer B solution with a mass fraction of 12% was obtained.

[0098] Step 2, preparation of vascular inner layer fibrous membrane

[0099] Under the environmental conditions of a temperature of 30° C. and a relative humidity of 60%, the prepared solution A was added to the syringe, and the distance between the two receiving plates was set at 5 cm. Apply a layer of lubricant (PEG) on the receiving roll before spinning, turn on the DC high voltage generator, adjust the spinning voltage to 30kV, adjust the spinning distance to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com