Dry testing transformer

A technology for testing transformers and transformers, applied in the directions of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of large center distance of transformers, increase production costs, increase economic burden, etc., and achieve a short manufacturing cycle. , Good performance and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

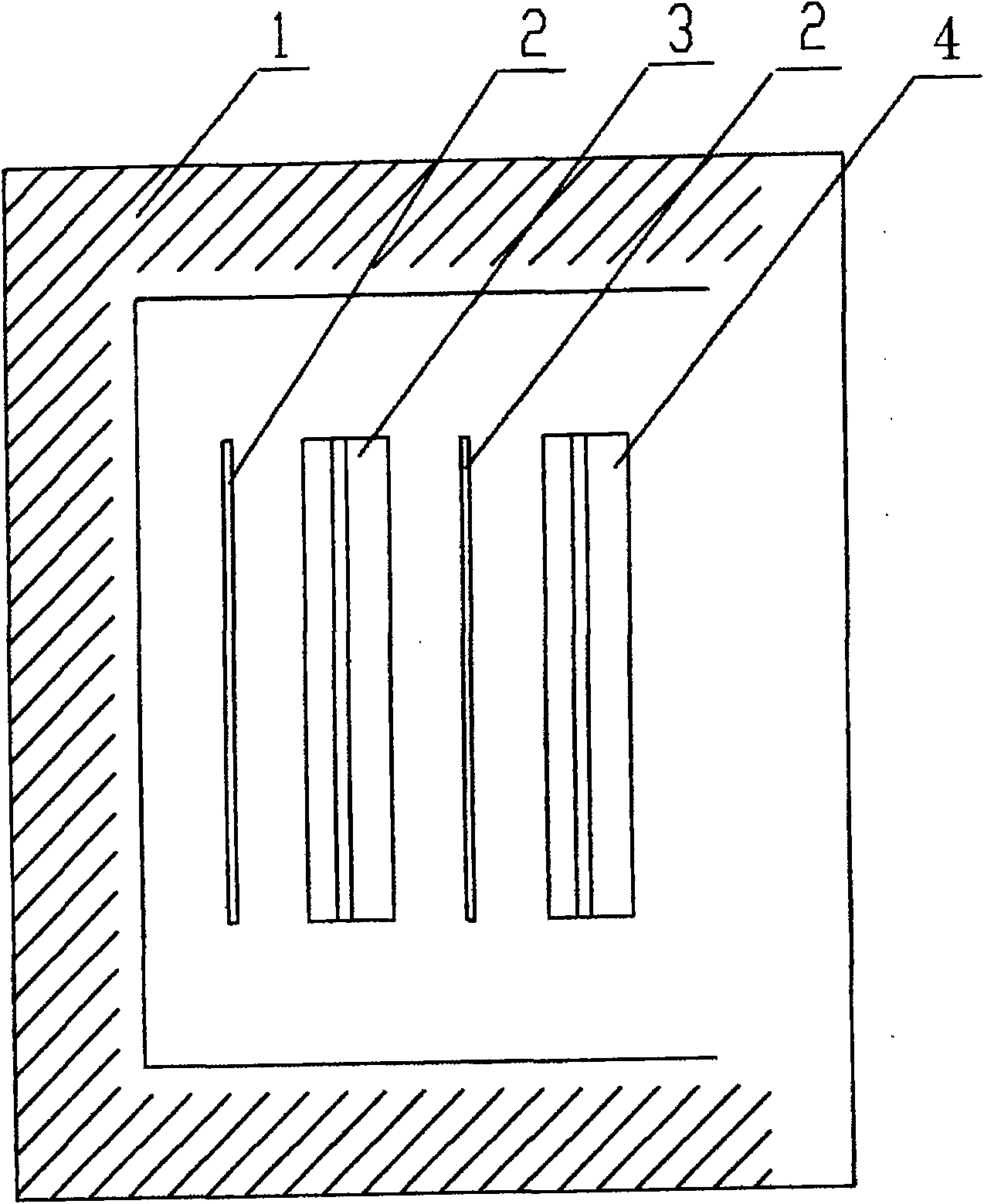

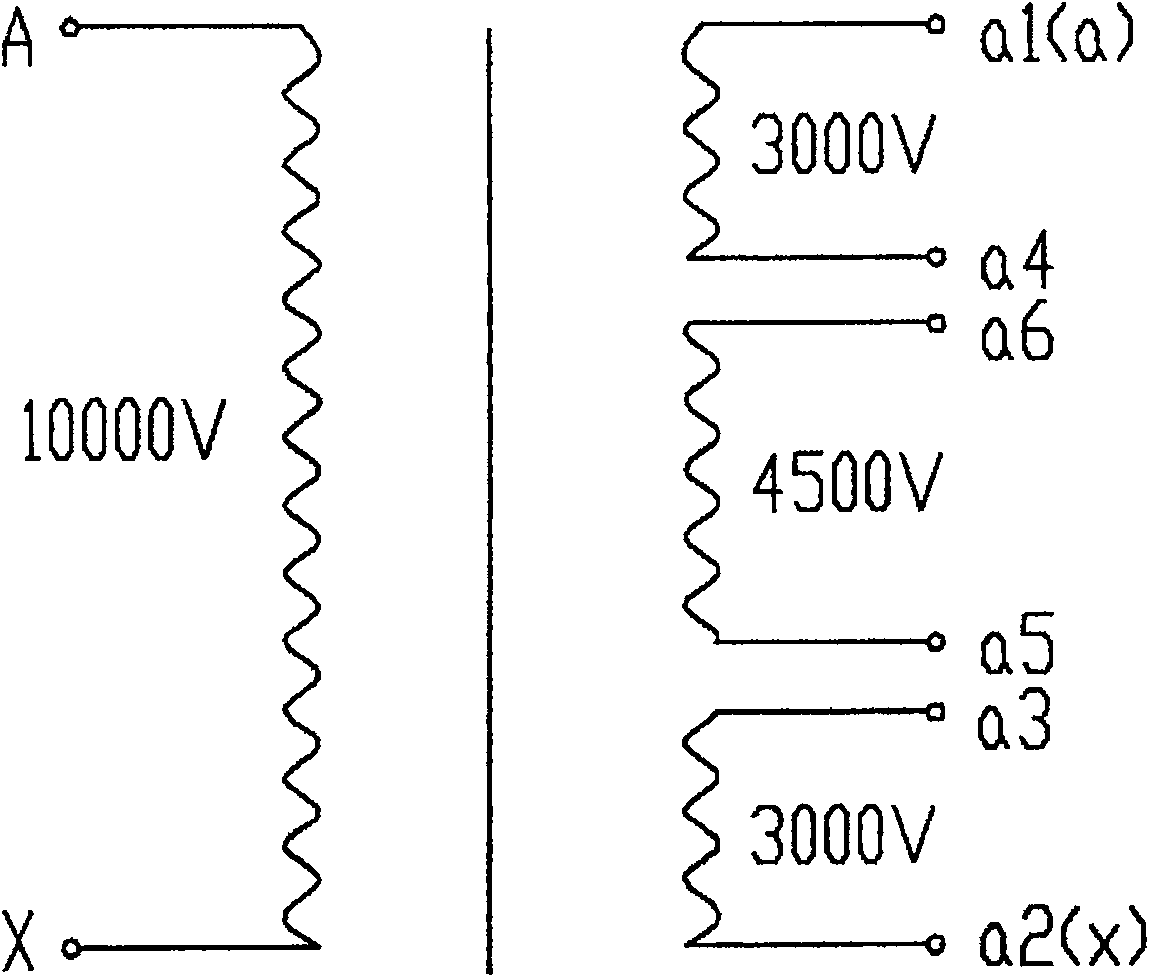

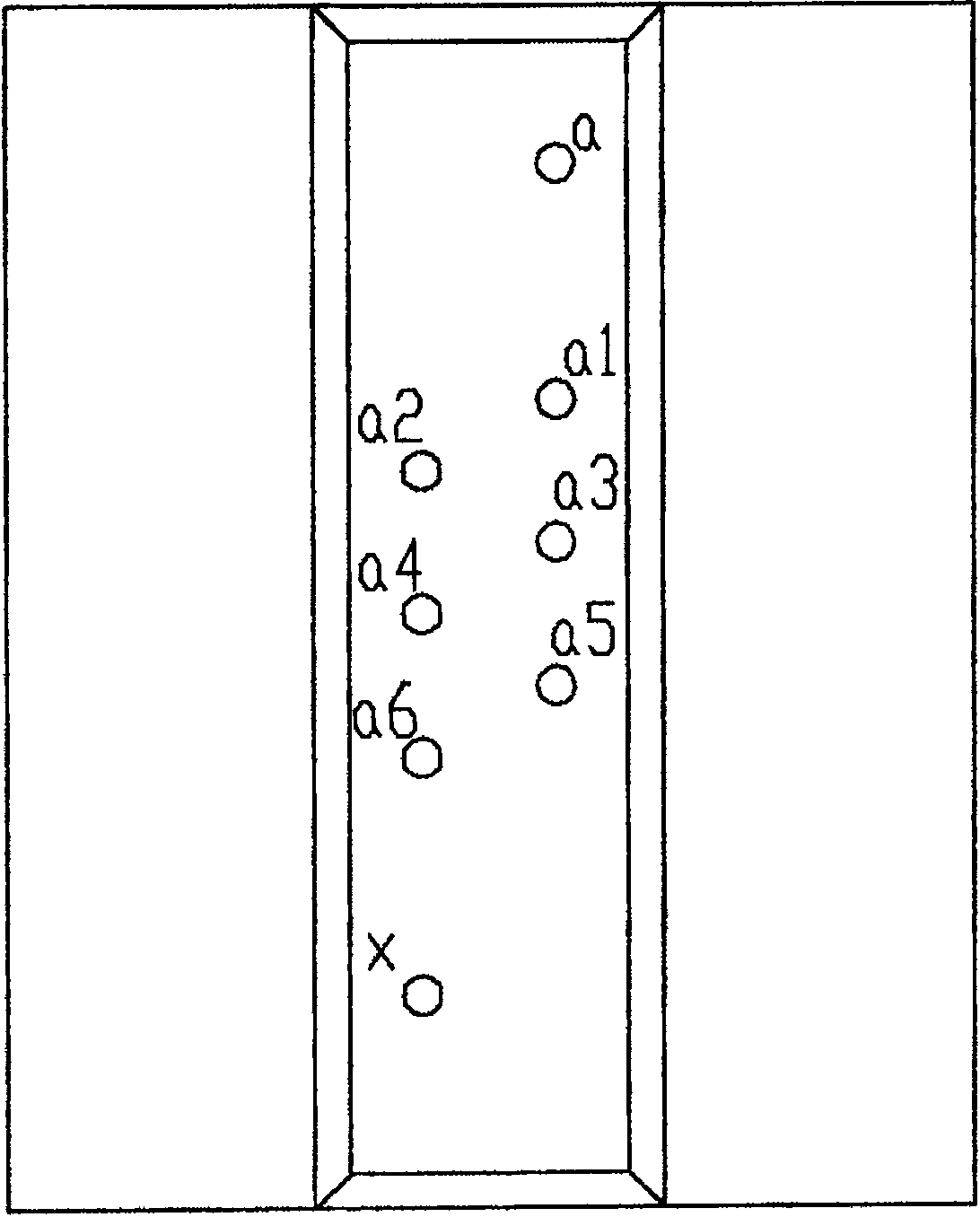

[0010] See attached figure 1 . attached figure 1 It is a schematic diagram of the winding arrangement of the present invention, from the appended figure 1 It can be seen that the double winding of the transformer is a primary winding 3 and a secondary winding 4 , and an insulating cylinder 2 is arranged between the primary winding 3 and the iron core 1 , and between the secondary winding 4 and the primary winding 3 . See attached figure 2 . attached figure 2 It is the principle connection diagram of the present invention, from the appended figure 2 It is clearly seen that the voltage set by A-X of the primary winding 3 is 10KV, and the voltage set by the secondary winding 4 is a combination of 3KV, 6KV, and 10.5KV respectively; The three independent sub-windings are respectively provided with six taps a1, a2, a3, a4, a5, and a6. The sub-windings a1-a4 are set on the upper part of the entire winding, and its output voltage is 3KV. The sub-windings a5-a6 It is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com