Improved machine for assembling and vulcanizing tires

A tire and machine technology, applied in tires, applications, household appliances, etc., can solve problems such as productivity loss and achieve high modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

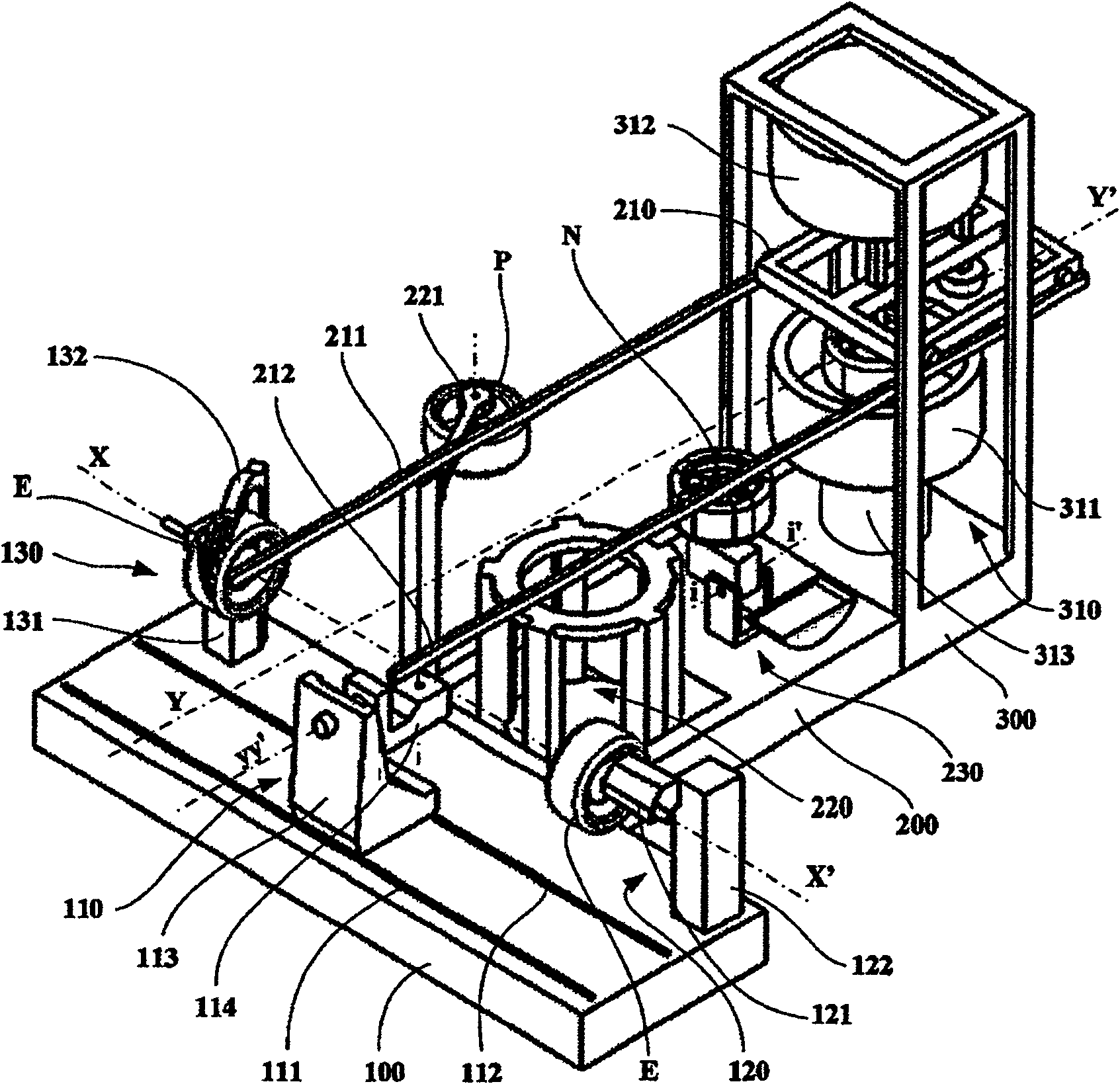

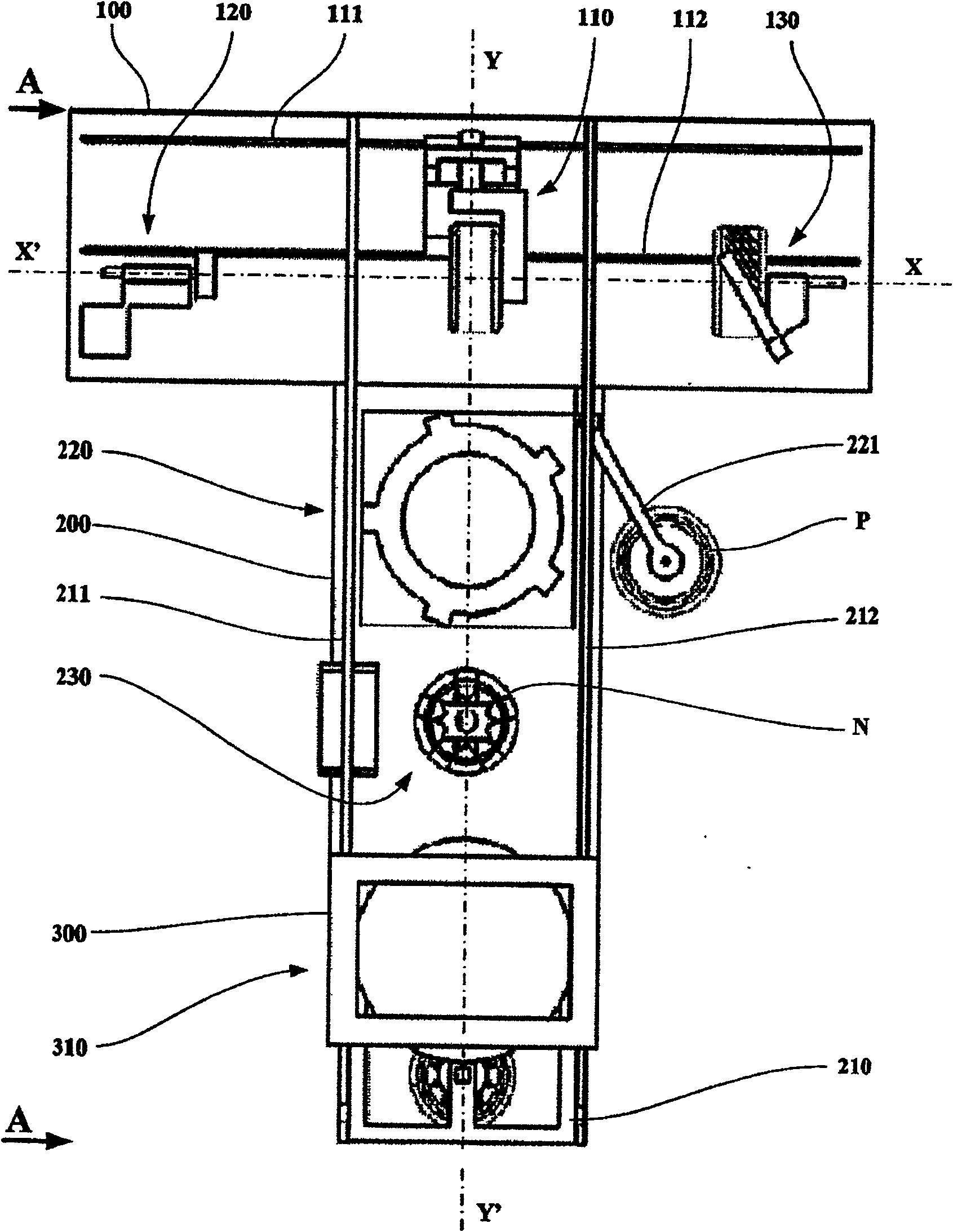

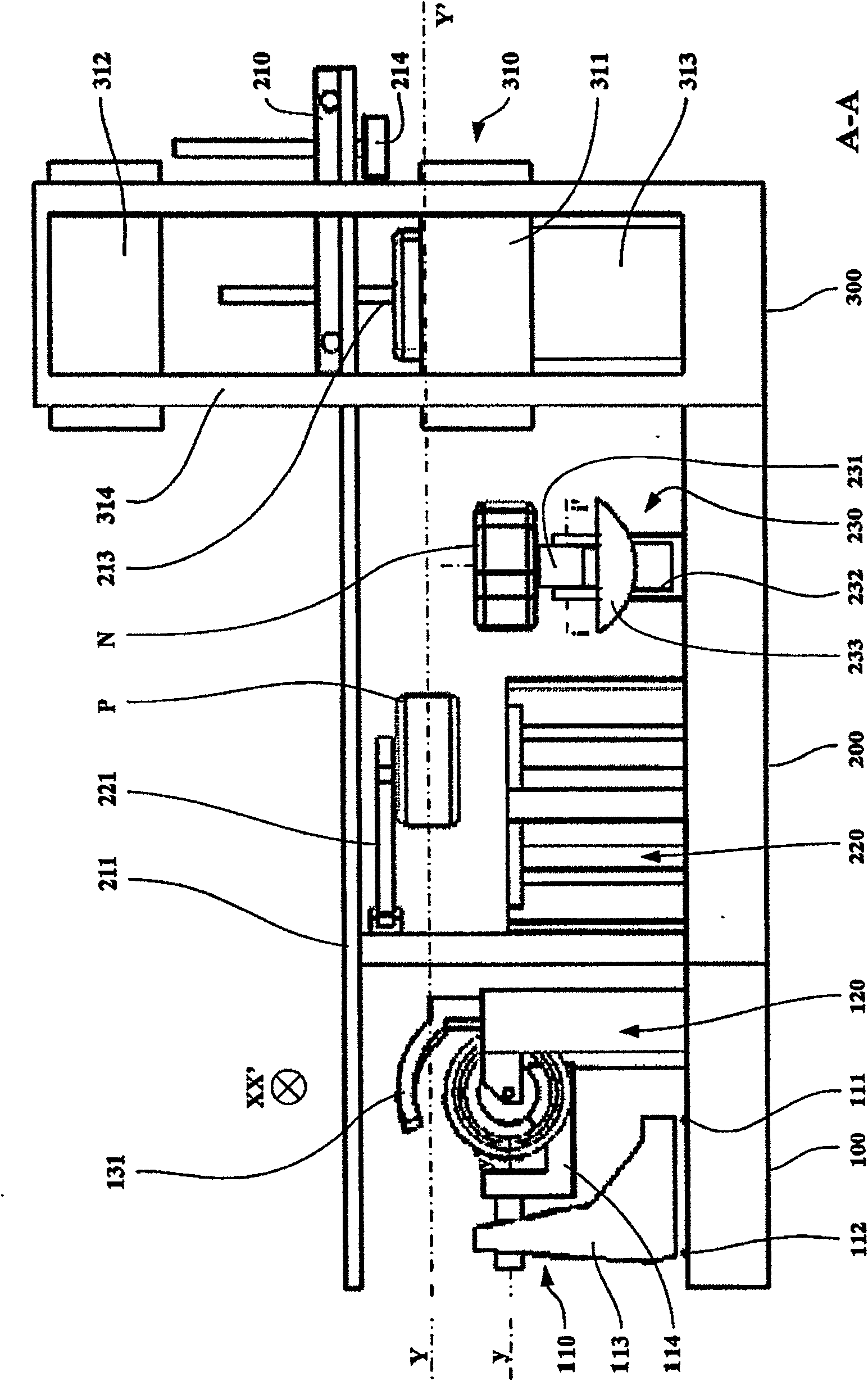

[0039] The same reference numerals are given in each figure, so that simultaneous reference can be made to several figures in order to clearly illustrate the relative arrangement of the different stations or elements of the machine.

[0040] For ease of reading, not all devices not necessary for an understanding of the invention have been shown in the figures. This therefore relates to means for dispensing the rubber compound onto the core, as described in EP0264600 or EP0400496 in a non-limiting manner. In the same way, devices for stacking cords (not shown) for carcass reinforcement or crown reinforcement are described in patent publications EP0243851, EP0248301, EP0353511, EP0519294, EP0519295, EP0580055, or EP0582215 . Finally, in order to obtain, by way of non-limiting example, a detailed description of a rigid core comprising a connecting rim and whose use is consistent with the machine forming the object of the present invention, reference is made to patent publication E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com