Method for making grid oxidizing layer

A gate oxide layer and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problems of decreased transconductance and driving current capability, device performance degradation, and reduced N-type semiconductor, etc. The effect of increasing the thickness of the gate oxide at the drain end, reducing the vertical electric field strength, and mitigating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

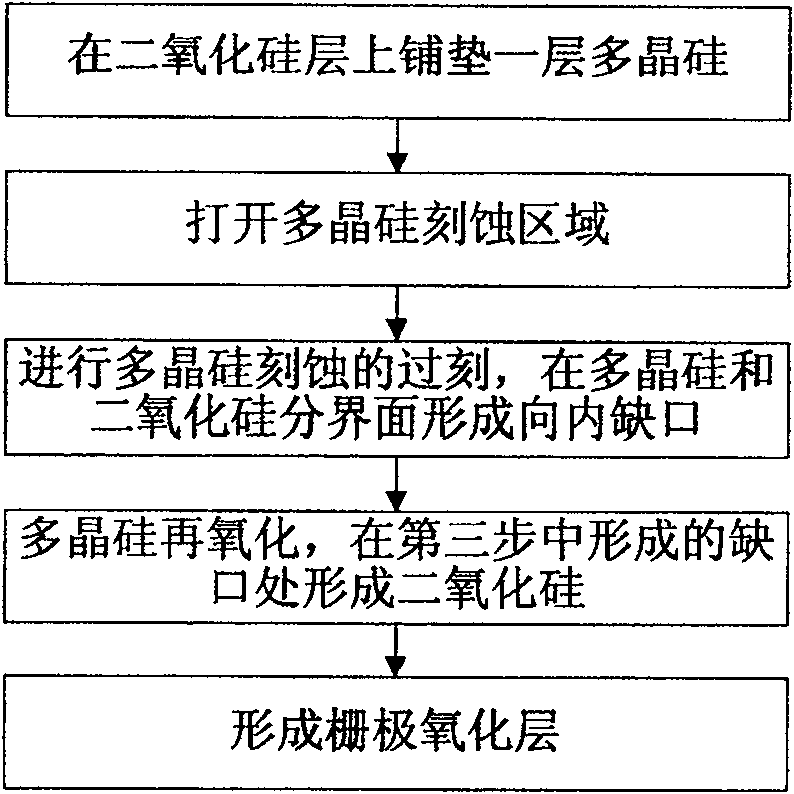

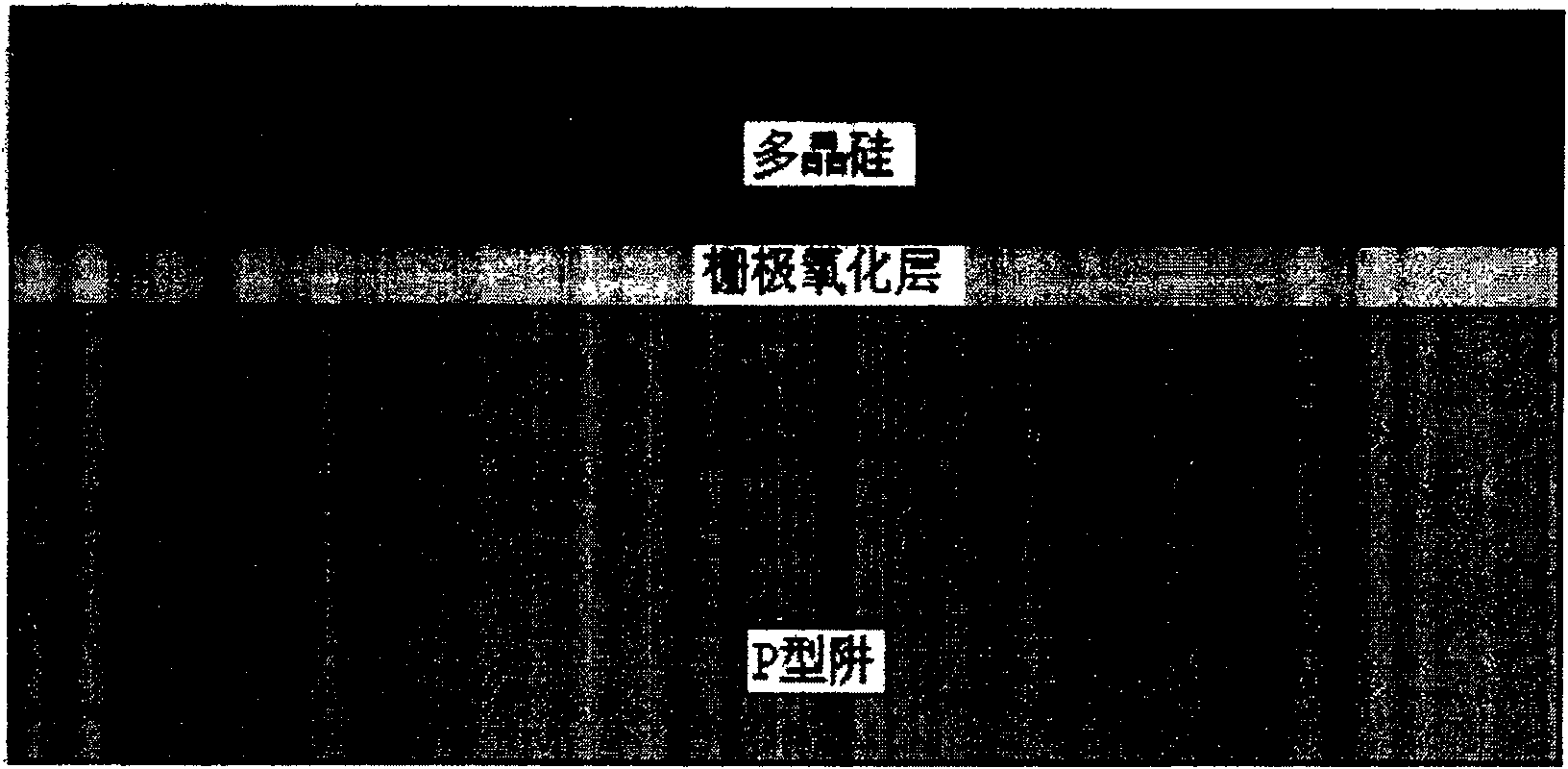

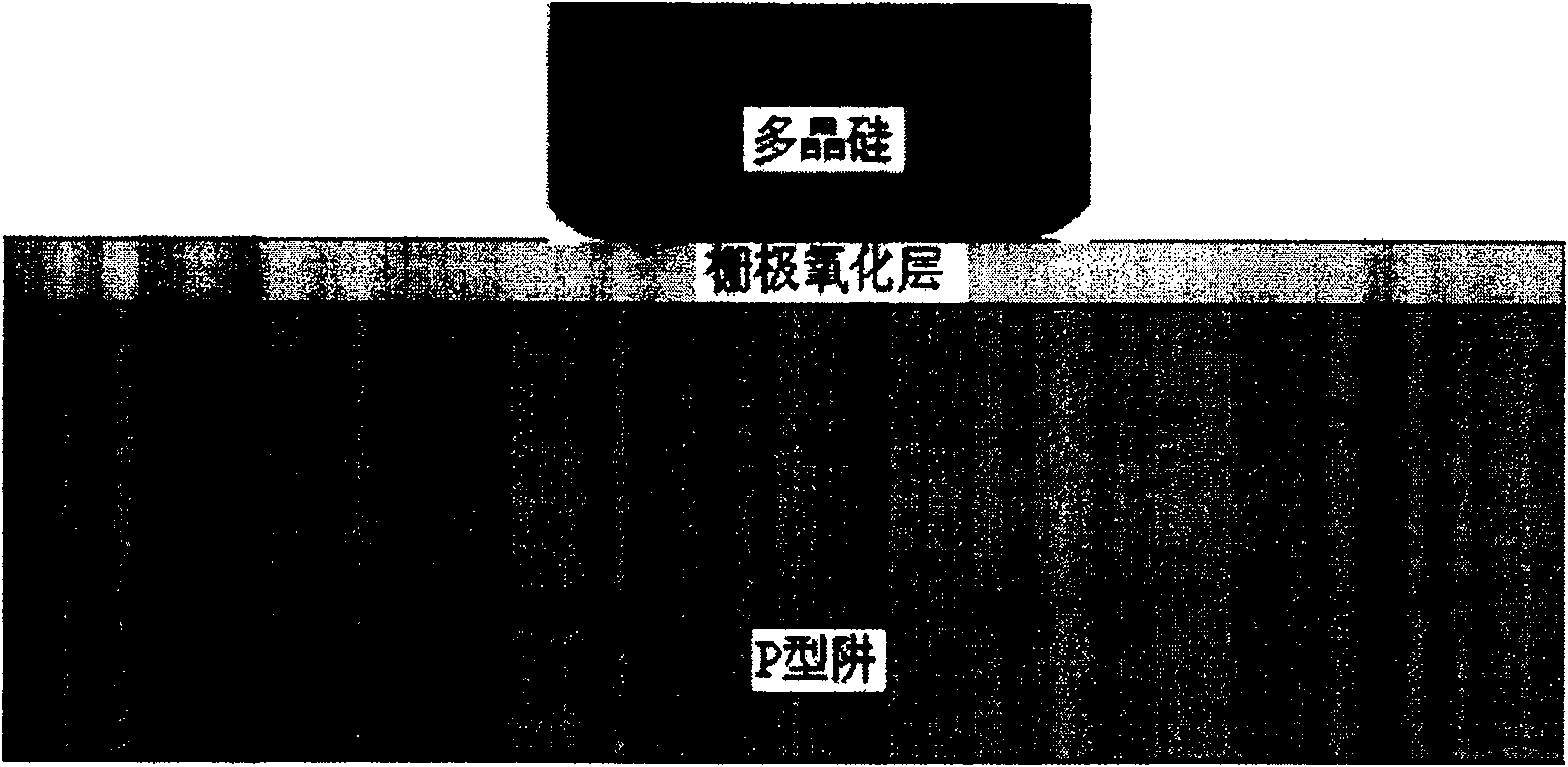

[0011] Such as figure 1 As shown, the gate oxide layer manufacturing method of the present invention includes the following steps: first, as figure 2 As shown, a layer of polysilicon is paved on the silicon dioxide layer on the P-type well, that is, the gate oxide layer, and the thickness of the paved silicon dioxide is between 1000 angstroms and 3000 angstroms according to different process requirements. Then, the polysilicon etching area is opened, and here the polysilicon etching area is opened by photolithography. Such as image 3 As shown, an inward gap is formed at the interface between polysilicon and silicon dioxide during polysilicon etching by dry etching. According to different process conditions, the depth of the inward notch in the horizontal direction does not exceed the boundary between the drain and the channel substrate. Next, if Figure 4 As shown, the polysilicon is re-oxidized, and silicon dioxide with a thickness of 30 angstroms to 150 angstroms is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com