Pneumatic thread tensioner and thread handling system

A processing system, tensioner technology, applied in thin material handling, transportation and packaging, textiles and papermaking, etc., can solve the problems of lateral deflection, yarn hydrodynamic damage, high air consumption, etc., to reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

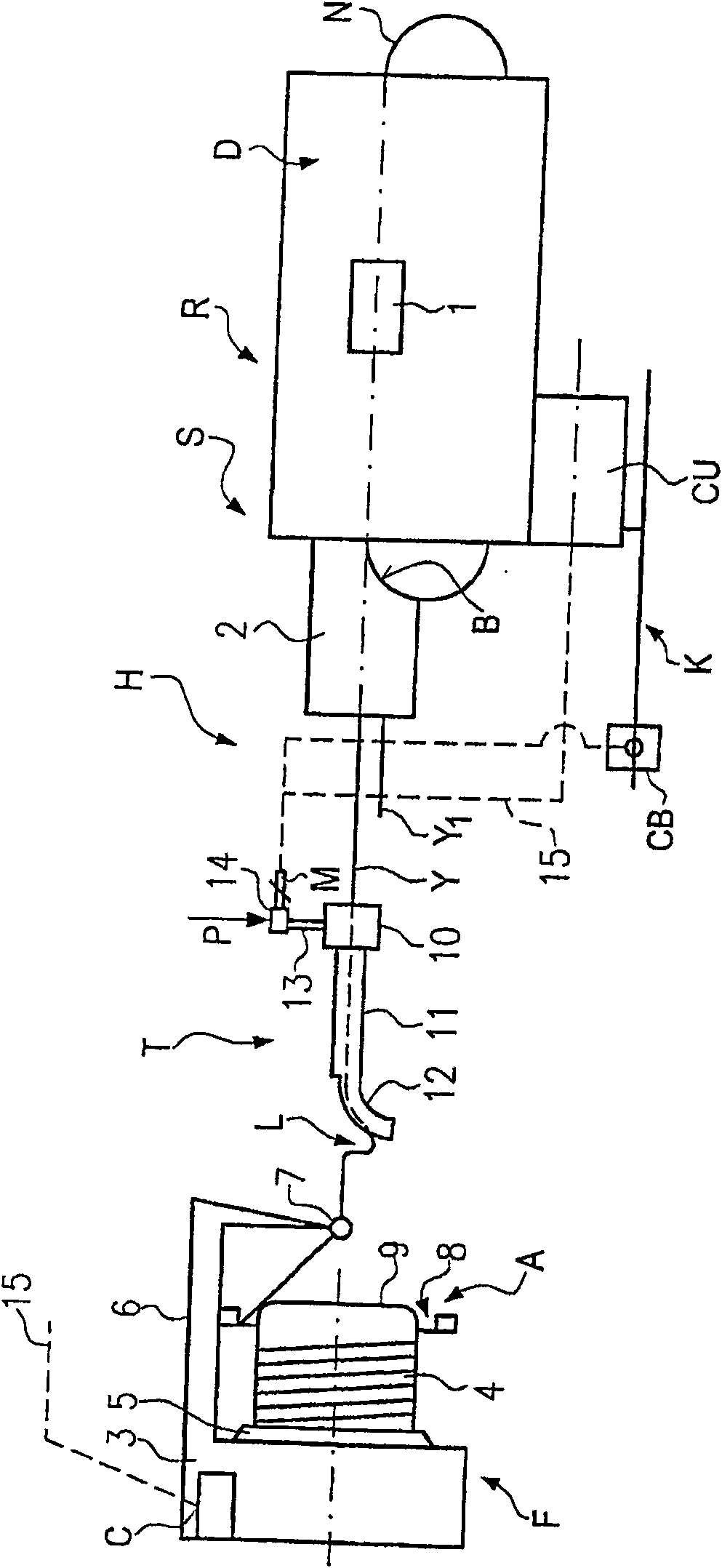

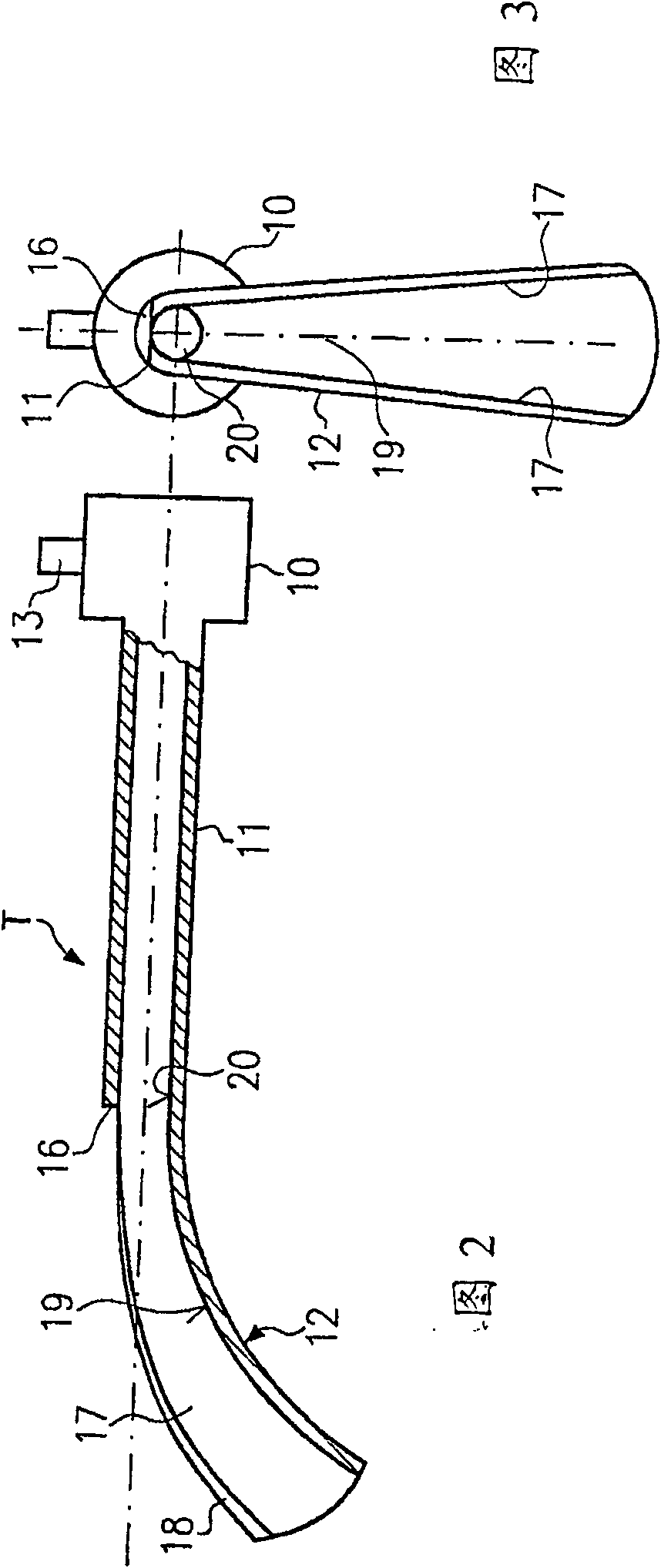

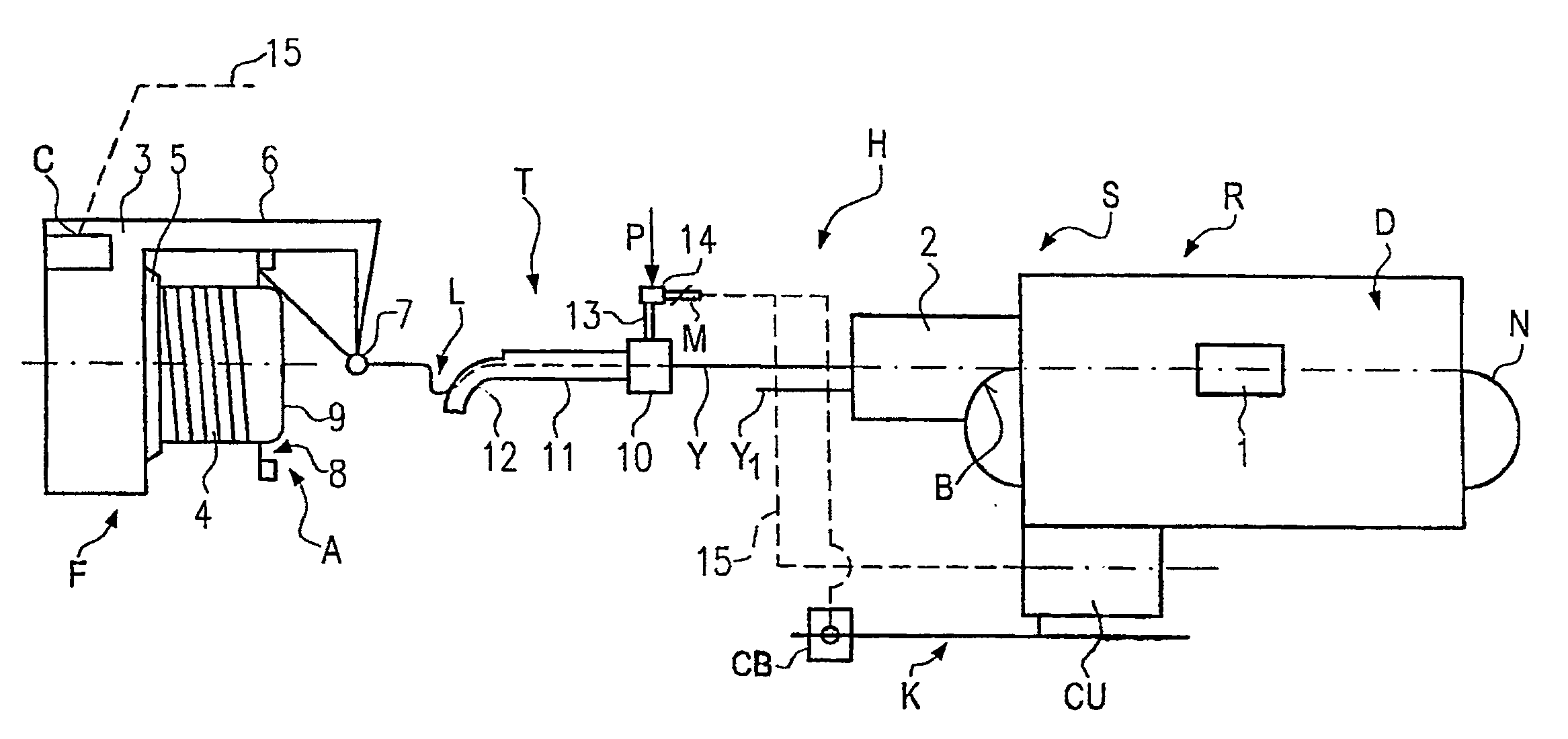

[0024] figure 1 The shown yarn processing system S comprises a weaving machine R, for example a rapier loom or even a braiding machine, and at least one yarn feeding device F and a yarn running path downstream of the yarn feeding device. Pneumatic Yarn Tensioner T.

[0025] A loom R, which is exemplified by a rapier loom, comprises a weaving shed D, a driven yarn guide and yarn take-off grippers B, N for inserting at least one yarn Y, Y1 from at least one yarn channel . The take-off gripper B places the end of the yarn in an insertion and selector device 2 and pulls the yarn to the middle of the knitting shed D, where it takes the yarn in zone 1 The thread end is transferred to the yarn take-off gripper N. The yarn take-off gripper then pulls the yarn entirely through the weaving shed and terminates the insertion process.

[0026]The yarn feeding device F includes a housing 3 and a fixed yarn storage barrel 4, and the yarn Y is wound on the yarn storage barrel in the form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com