Walking refuse rock rapid filling machine

A filling machine and walking technology, applied in filling materials, safety devices, mining equipment, etc., can solve the problems of cumbersome installation, operation, maintenance and repair, high energy consumption, complex structure, etc., to solve the phenomenon of scattered gangue and low energy consumption , The effect of simple and compact component structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and specific embodiments:

[0027] The walking type gangue fast filling machine of the present invention is mainly designed based on the needs of mine replacement filling engineering. It is suitable for roadway width of 1.5-4.2 meters and roadway height of 2.2-6 meters. It is a continuous gangue filling equipment. It is mainly used for replacement filling in underground mines, and can also be used for filling of other mine roadways and various engineering tunnels.

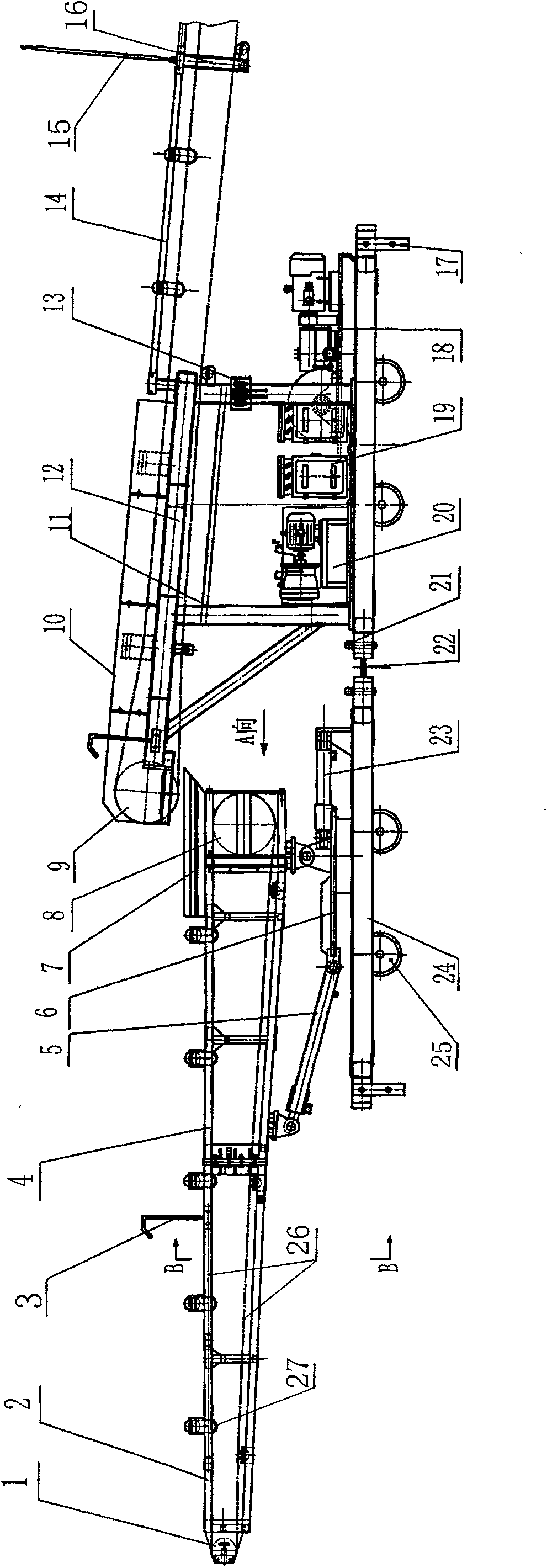

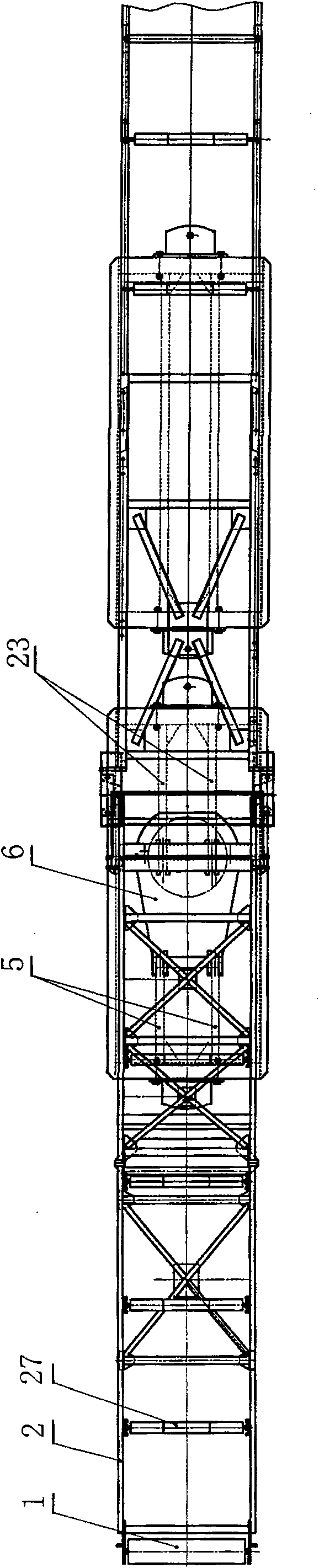

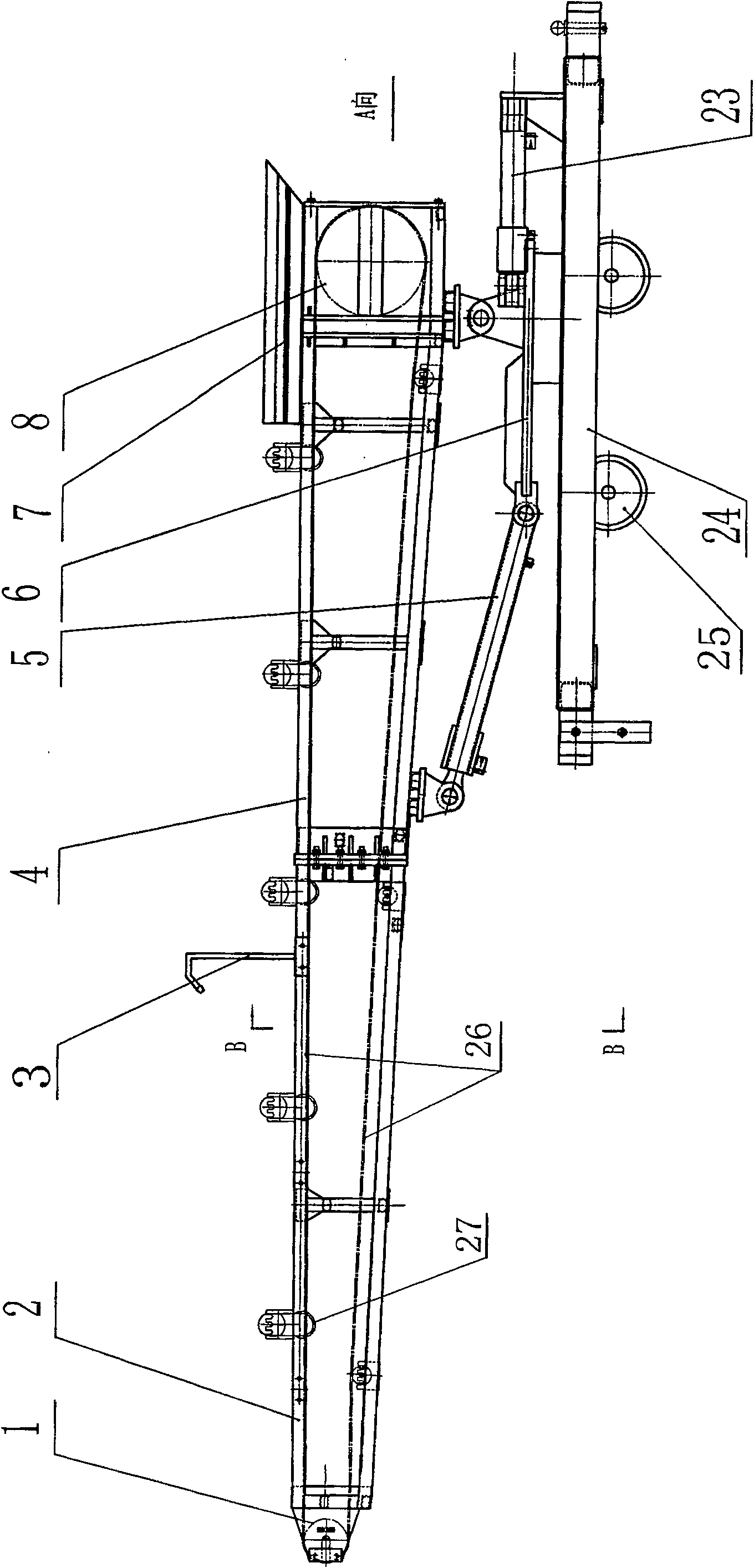

[0028] The invention is like figure 1 , figure 2 , image 3 , Figure 4 Shown, where image 3 for figure 1 The enlarged schematic diagram of the first half of the structure, Figure 4 for figure 1 An enlarged schematic diagram of the structure in the second half.

[0029] The walking type gangue fast filling machine of the present invention includes: a gangue throwing part, a reloading part, a walking part, a hydraulic par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com