Method of manufacturing spectacle lens

A manufacturing method and technology for spectacle lenses, which are applied in the directions of manufacturing tools, glasses/goggles, glasses/protective glasses, etc., can solve problems such as difficulty in sharpness adjustment, positioning control and marking accuracy, and machining axis offset, and achieve easy identification. , The effect of suppressing positioning errors and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Preferred modes for carrying out the present invention will be described below with reference to the drawings.

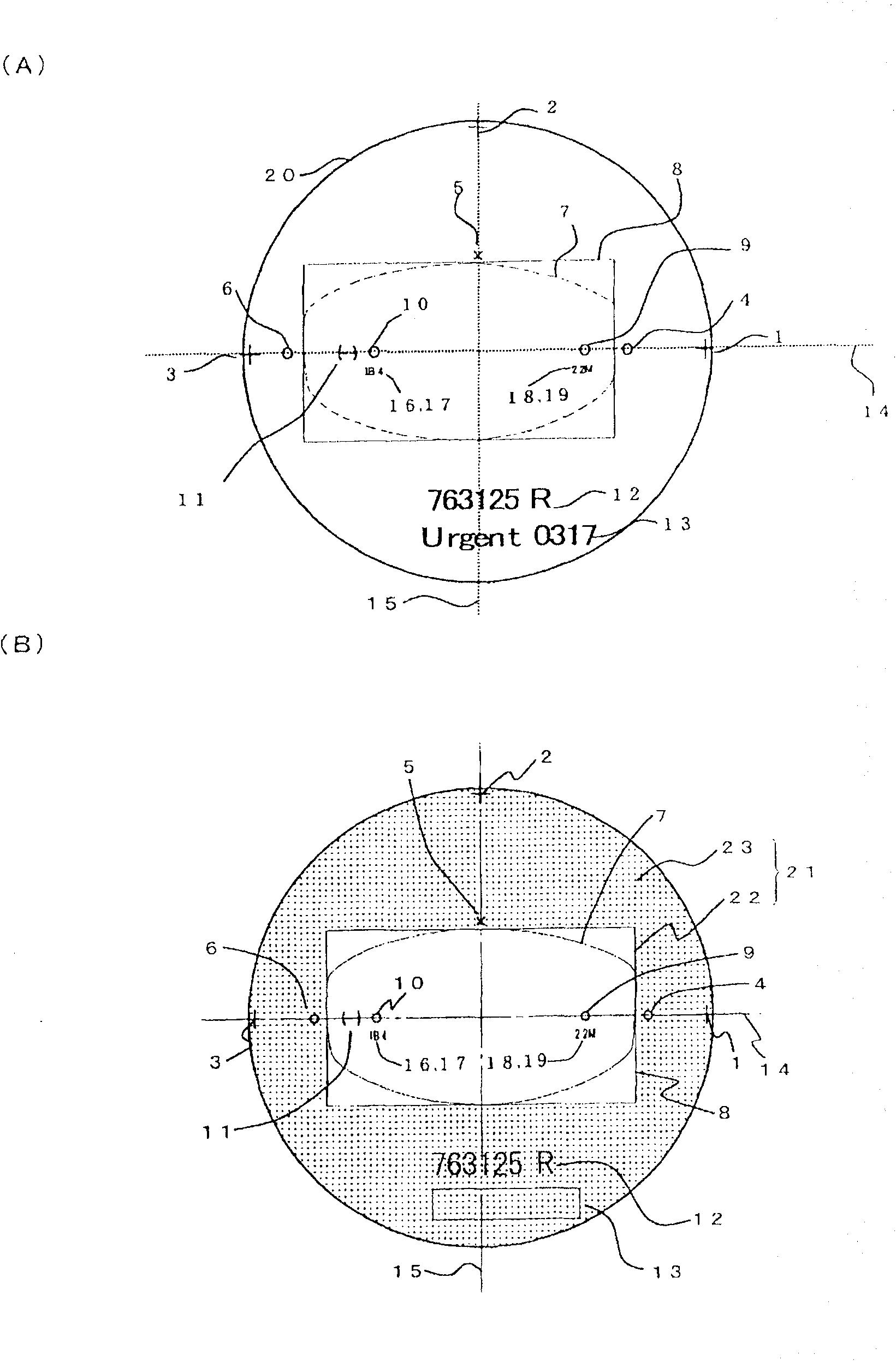

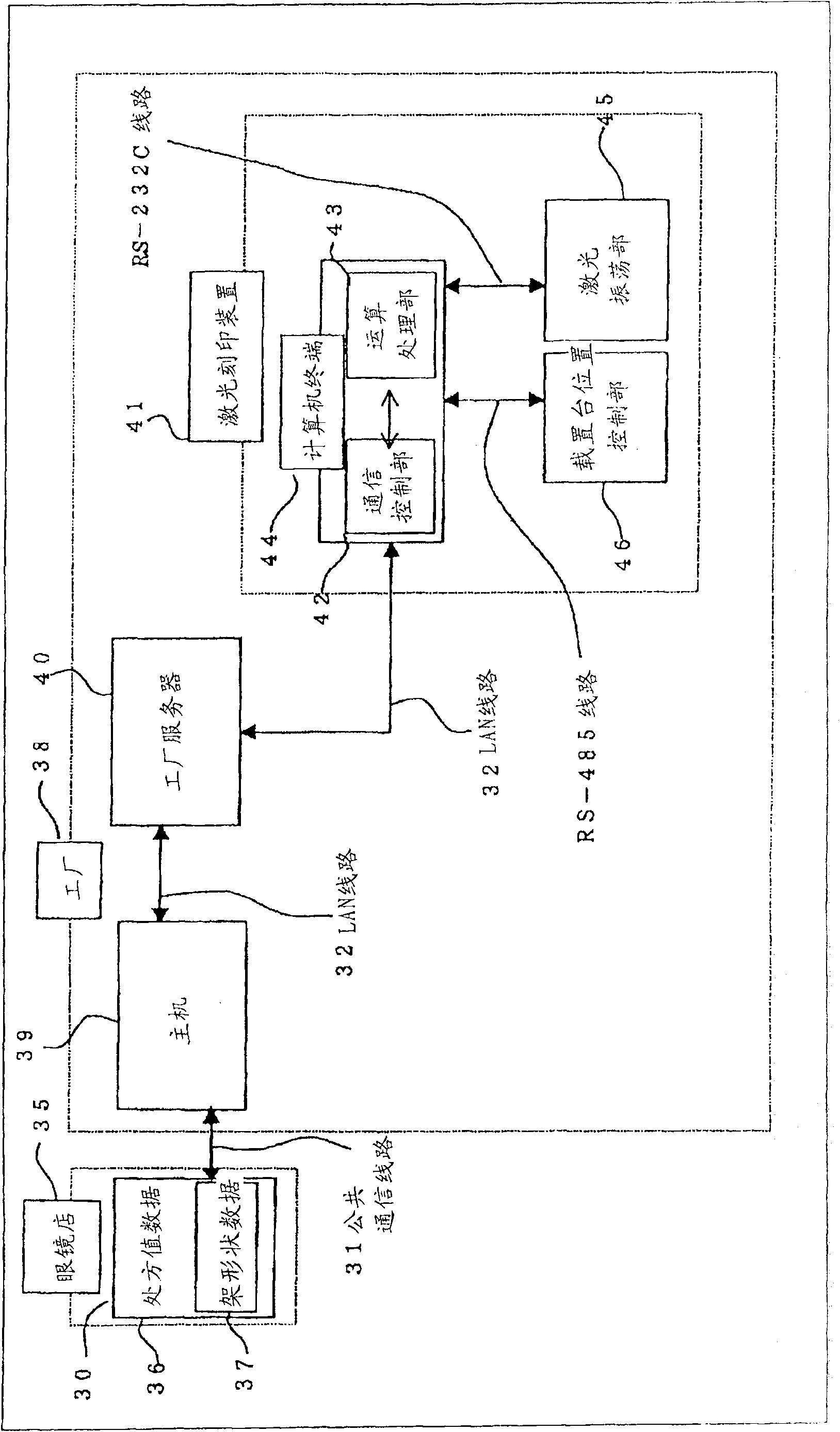

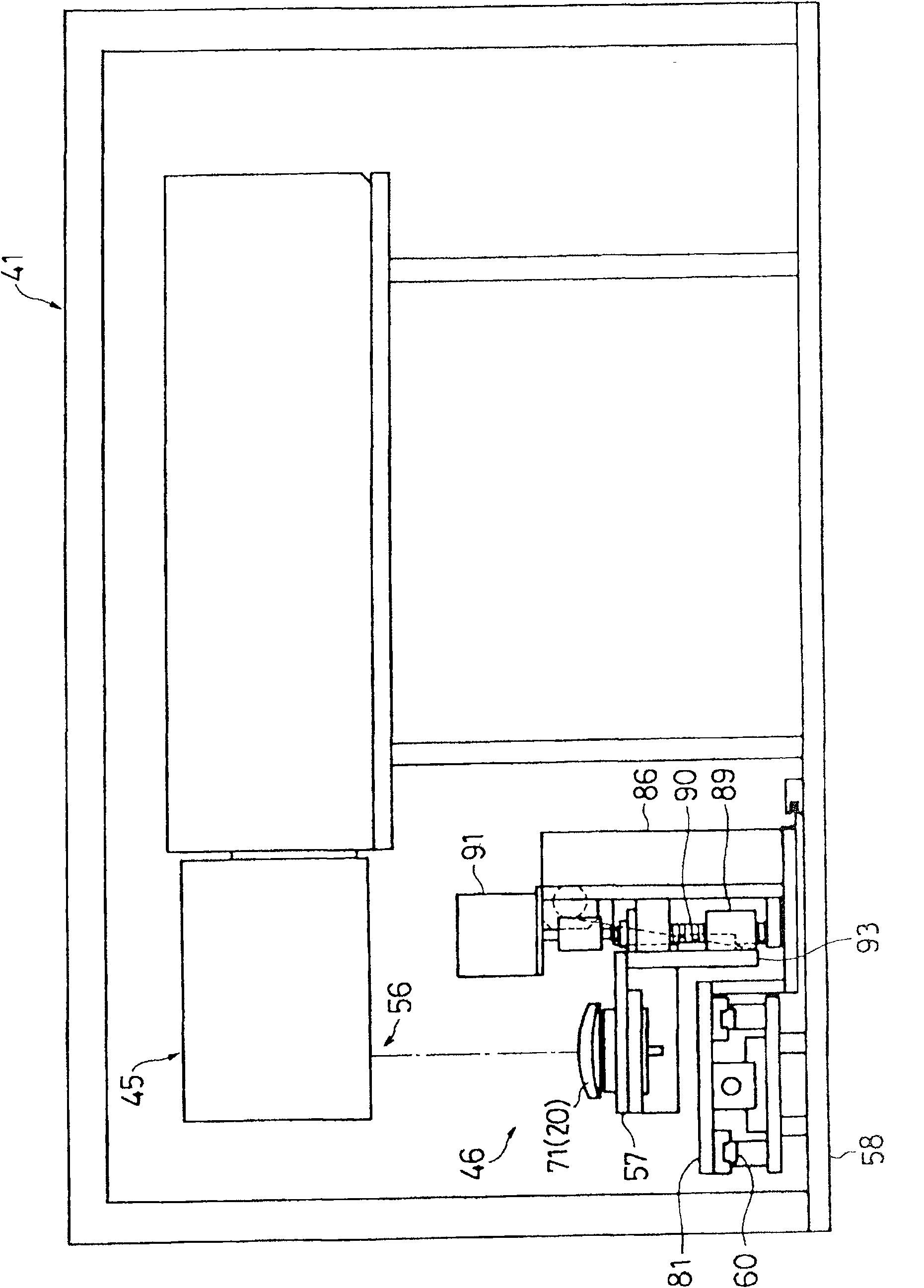

[0076] figure 1 It is a figure which shows the progressive-power lens in which various relevant information was imprinted in one Example of the spectacle lens of this invention. figure 2 It is a figure which shows the outline of the spectacle lens manufacturing system which implements one Example of the spectacle lens manufacturing method of this invention, and concretely demonstrates centering on a laser marking system.

[0077] exist figure 1 In this progressive power lens 20 (hereinafter referred to as the lens 20 ), spectacle lens-related information, spectacle frame-related information, prescription value and layout-related information, and manufacturing-related information are engraved.

[0078] Spectacle lens-related information includes, for example, product information 11 for specifying a supplier and a product name of the lens 20 , refractive ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com