Method for preparing highly pure cadmium telluride

A cadmium telluride, high-purity technology, applied in the direction of cadmium sulfide, etc., can solve the problems of complex equipment, long production cycle, poor safety, etc., and achieve the effects of high photoelectric conversion rate, large equipment capacity and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

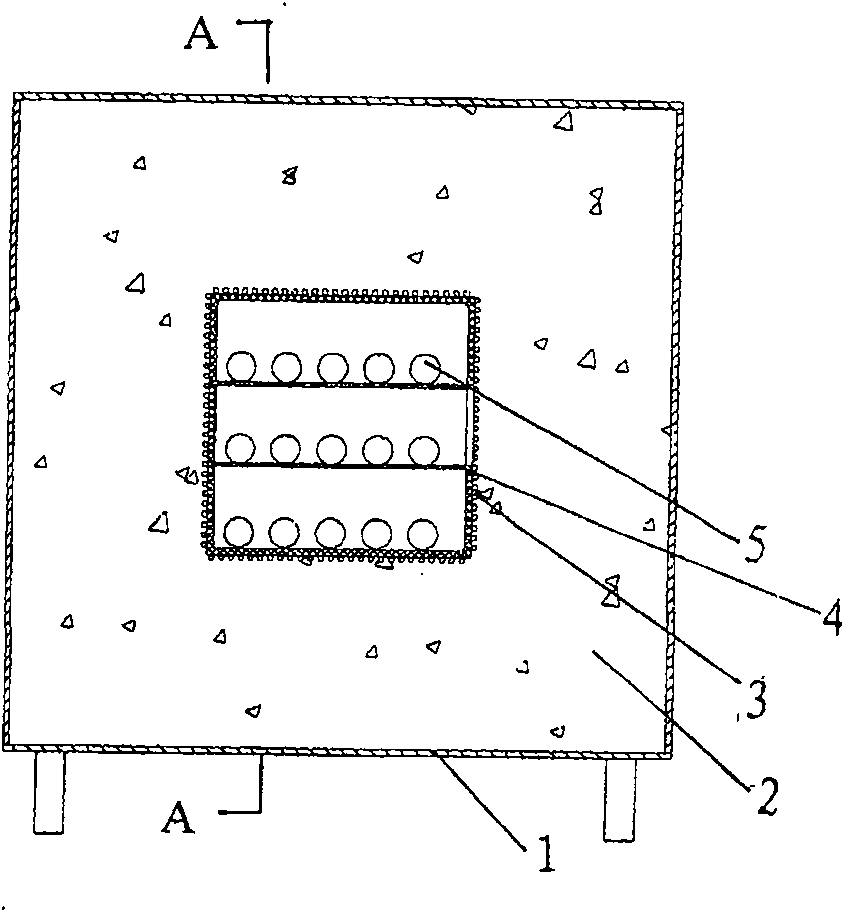

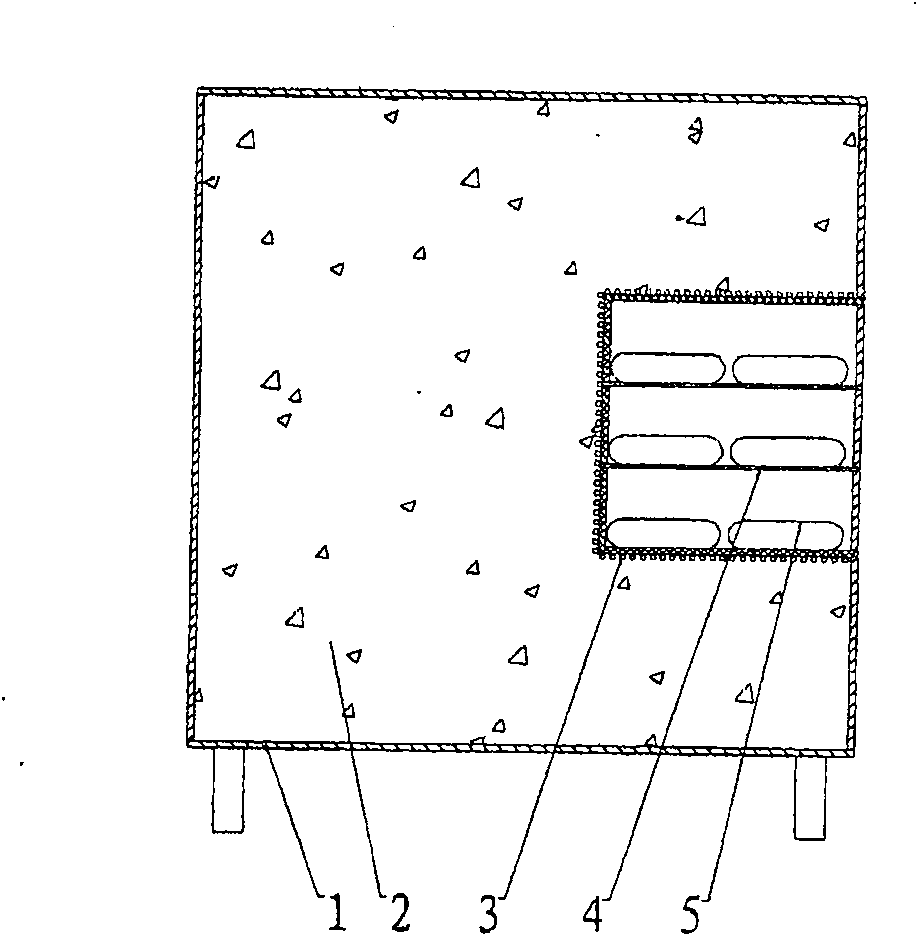

Embodiment 1

[0017] Mix 5N tellurium and 5N cadmium in a molar ratio of 1:1, crush or grind the mixture into pellets with a particle size of 13 μm, put 500 grams of pellets into the quartz tube 5, and evacuate to 1 Pa Seal, then put the sealed quartz tube into the cadmium telluride synthesis furnace 1, the synthesis furnace is provided with an insulating layer 2, a heating wire 3, a heat shield 4 and a quartz tube 5, and the heat shield covers the furnace cavity of the synthesis furnace. It is divided into multiple synthesis chambers, and each synthesis chamber is placed with several sealed quartz tubes filled with tellurium and cadmium pellets. The heating system of the synthesis furnace is turned on, and the temperature is raised at a rate of 90°C / hour. When the temperature of the synthesis furnace rises to 115° C., constant temperature reaction for 40 minutes, cooling at a rate of 70° C. / hour, down to room temperature, and discharge to obtain 495 grams of 5N cadmium telluride product wit...

Embodiment 2

[0019] Mix 5N tellurium and 5N cadmium in a molar ratio of 1:1, crush or grind the mixture into pellets with a particle size of 8 μm, put 550 grams of pellets into the quartz tube 5, and evacuate to 1.1 pa seal, and then put the sealed quartz tube into the cadmium telluride synthesis furnace 1, the synthesis furnace is provided with an insulating layer 2, a heating wire 3, a heat shield 4 and a quartz tube 5, and the heat insulation plate will cover the furnace of the synthesis furnace. The cavity is divided into multiple synthesis chambers, and each synthesis chamber is placed with multiple sealed quartz tubes filled with tellurium and cadmium pellets. The heating system of the synthesis furnace is turned on, and the temperature is raised at a rate of 95°C / hour. to 120°C, react at constant temperature for 35 minutes, lower the temperature at a rate of 75°C / hour, and discharge the material at room temperature to obtain 500 g of 5N cadmium telluride product with a conversion rat...

Embodiment 3

[0021] Mix 5N tellurium and 5N cadmium in a molar ratio of 1:1, crush or grind the mixture into pellets with a particle size of 10 μm, put 600 grams of pellets into the quartz tube 5, and vacuumize to 1.2 pa seal, and then put the sealed quartz tube into the cadmium telluride synthesis furnace 1, the synthesis furnace is provided with an insulating layer 2, a heating wire 3, a heat shield 4 and a quartz tube 5, and the heat insulation plate will cover the furnace of the synthesis furnace. The cavity is divided into multiple synthesis chambers, and each synthesis chamber is placed with multiple sealed quartz tubes filled with tellurium and cadmium pellets. The heating system of the synthesis furnace is turned on and the temperature is raised at a rate of 100°C / hour. to 125°C, react at constant temperature for 40 minutes, lower the temperature at a rate of 80°C / hour, drop to room temperature and discharge, and obtain 590 g of 5N cadmium telluride product with a conversion rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com