Fuel injection valve

The technology of a fuel injection valve and a fuel injection device is applied in the field of the injection valve of the fuel injection device of an internal combustion engine to achieve the effects of ensuring work, low temperature and large structural volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

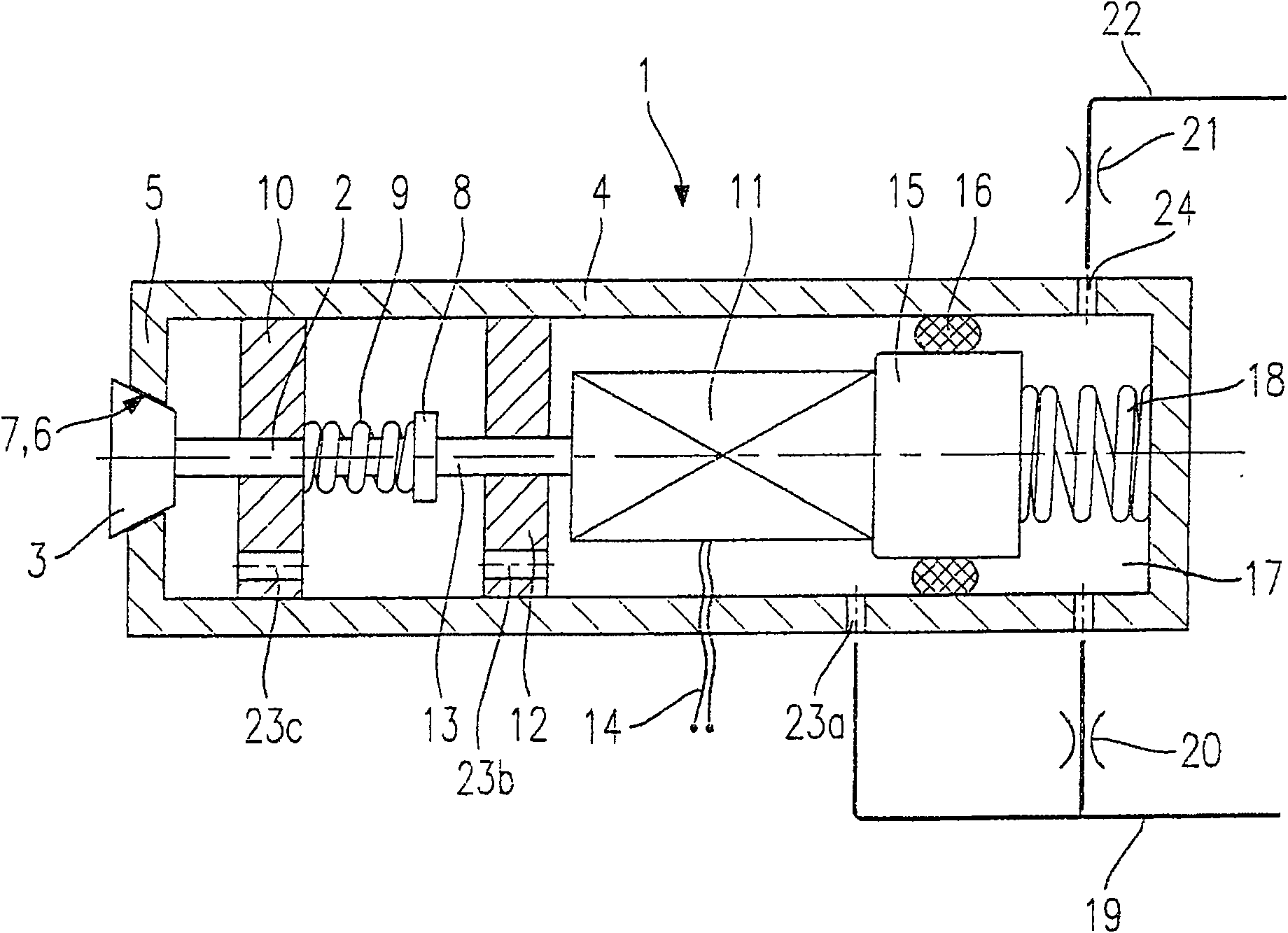

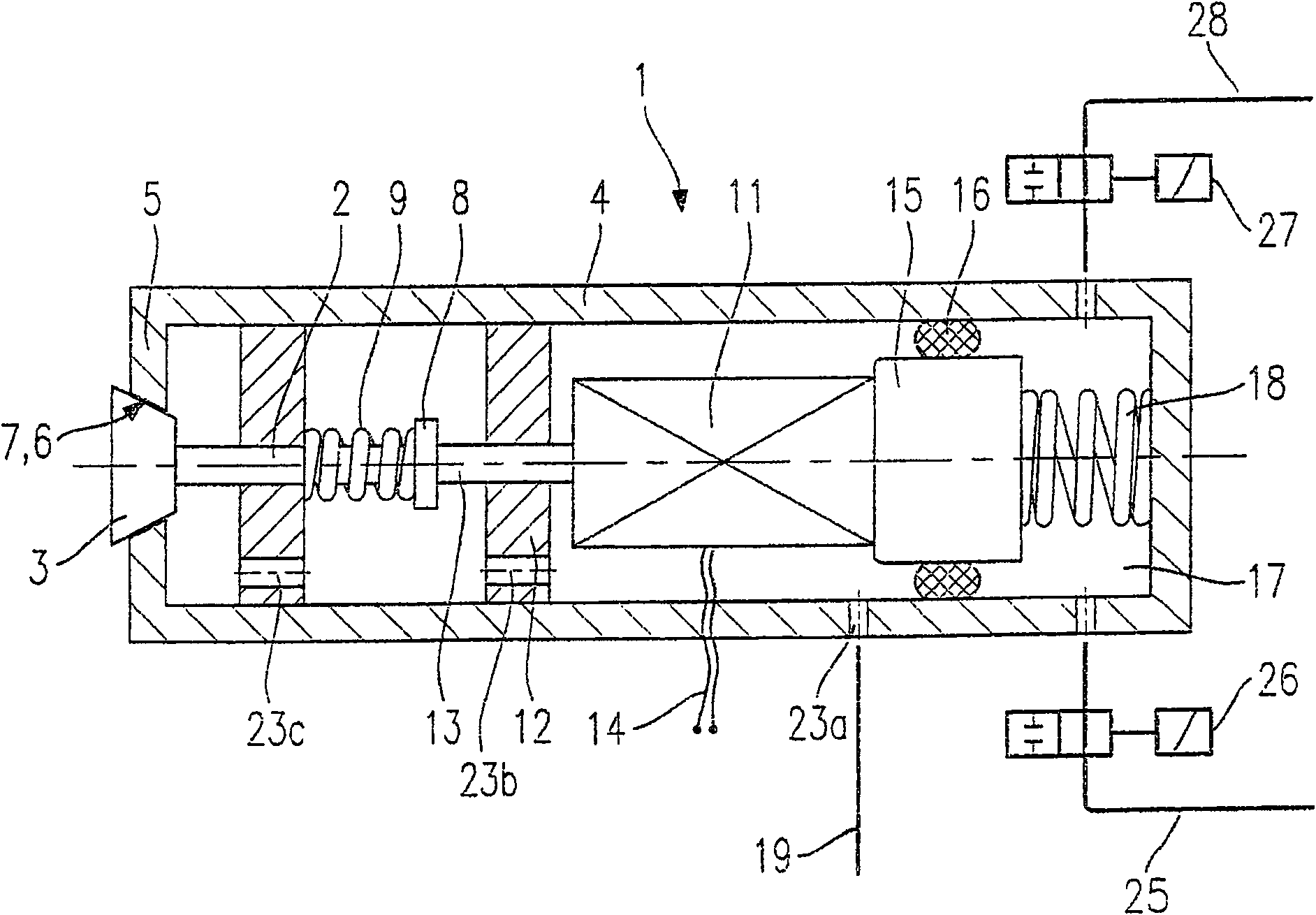

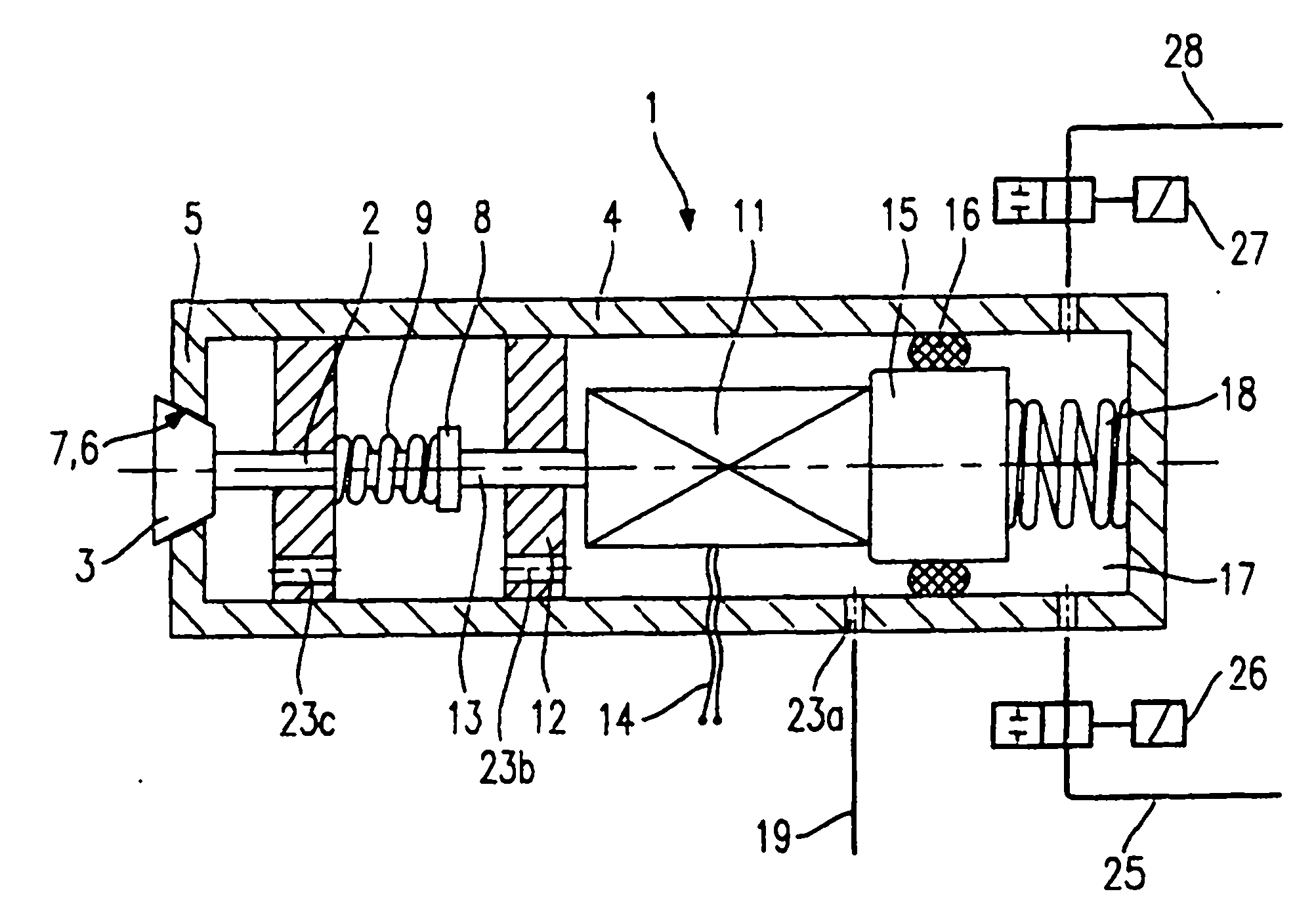

[0025] figure 1 A schematic sectional view is shown schematically as a schematic diagram of a fuel injector 1 . This is a fuel injector 1 with an outwardly openable valve needle 2 which is connected to a valve closure 3 . A valve seat carrier 5 integrally formed or formed integrally with the valve body 4 has a valve seat surface 6 which forms a sealing surface 7 with the valve closure part 3 . Valve needle 2 has a spring stop 8 on which valve spring 9 is supported. The second end of the valve spring 9 bears against a guide sleeve 10 for the valve needle 2 . The valve spring 9 exerts a preload force on the valve needle 2 via the spring stop 8 , which forces the valve closure part 3 against the sealing seat surface 6 .

[0026] The actuator 11 is connected to an actuator plunger 13 guided in the spacer 12 . The actuator 11 can be powered via the connection line 14 . At the end of the actuator 11 facing away from the sealing surface 6 , the actuator 11 is connected to a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com