Bipolar plate for fuel cell comprising a housing for measuring connector

A fuel cell and bipolar plate technology, which is applied to fuel cell parts, fuel cells, fuel cell additives, etc., can solve the problems of increasing the manufacturing cost of bipolar plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

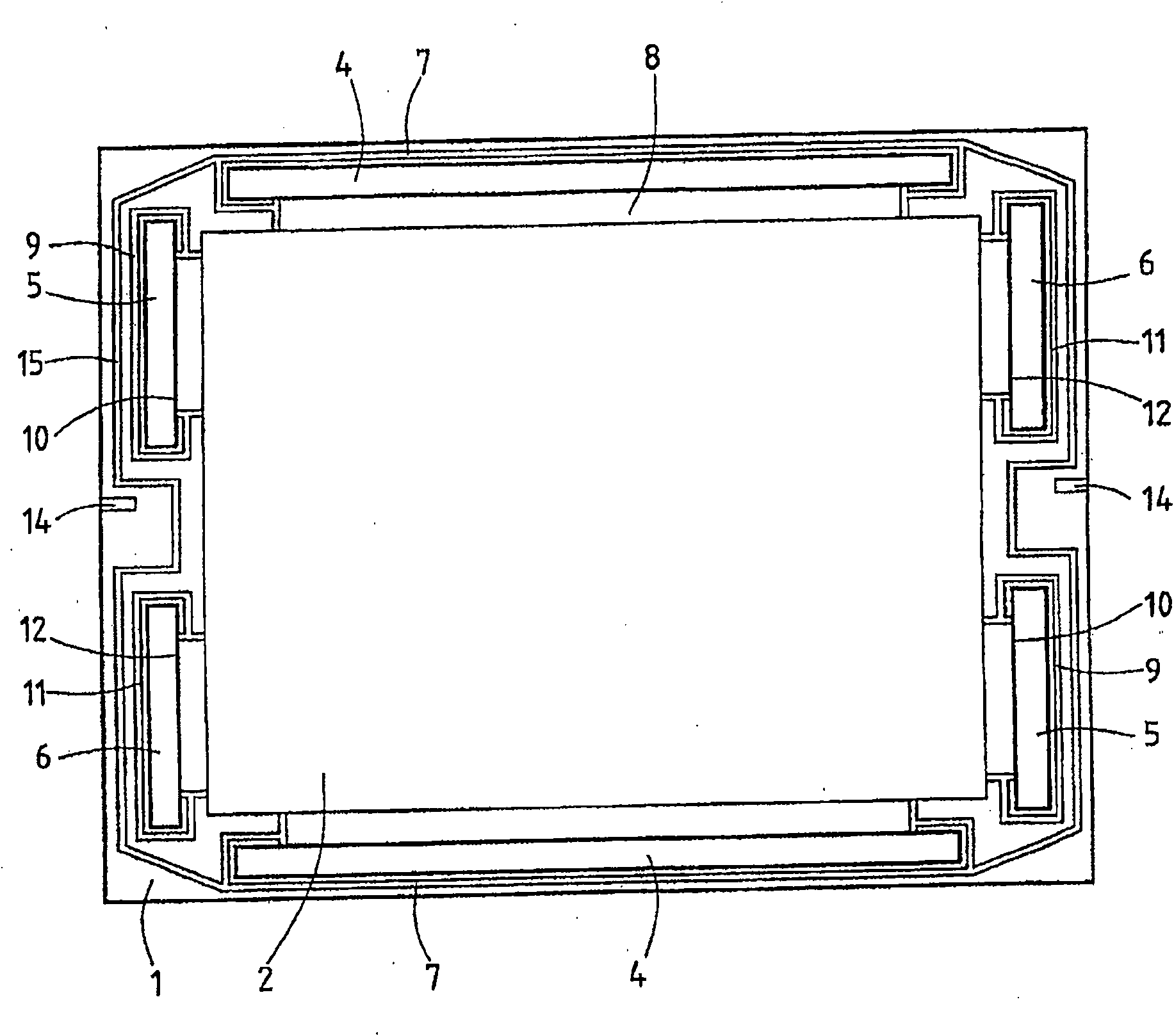

[0016] [16] in figure 1 Only a single surface can be seen in the bipolar plate shown, which consists of a cathodic or anodic bipolar half plate 1 and a correspondingly anodic or cathodic bipolar half plate, both of which are The two bipolar half-plates are interconnected by their inner surfaces. Each of the two bipolar half plates is made of, for example, a metal plate made of stainless steel. The central part 2 of each bipolar half-plate constitutes the active area, and has a ribbed net 3, which is used to ensure that the flow of fluid is well distributed on the outer surface of each bipolar half-plate, and to ensure the flow of the heat-carrying fluid The flow is well distributed between the two bipolar half plates. The two bipolar half-plates comprise at their periphery cutouts 4, 5, 6 for forming fluid boxes for the supply and discharge of the different fluids necessary for the operation of the cell.

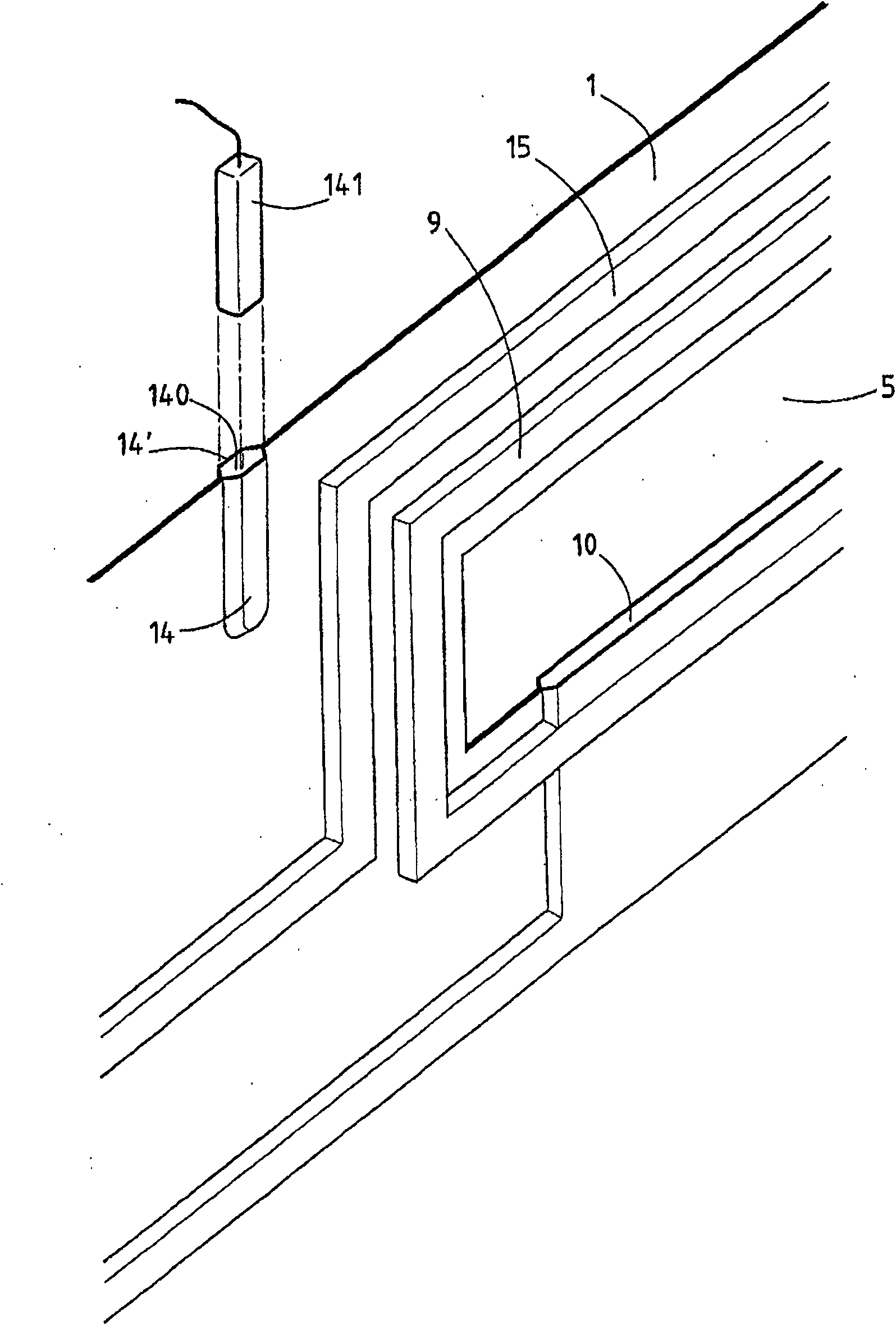

[0017] [17] Especially in the upper and lower parts of the bipolar p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com