Apparatus and method for fast arc extinction in plasma process

A plasma and process technology, used in plasma welding equipment, plasma, arc welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

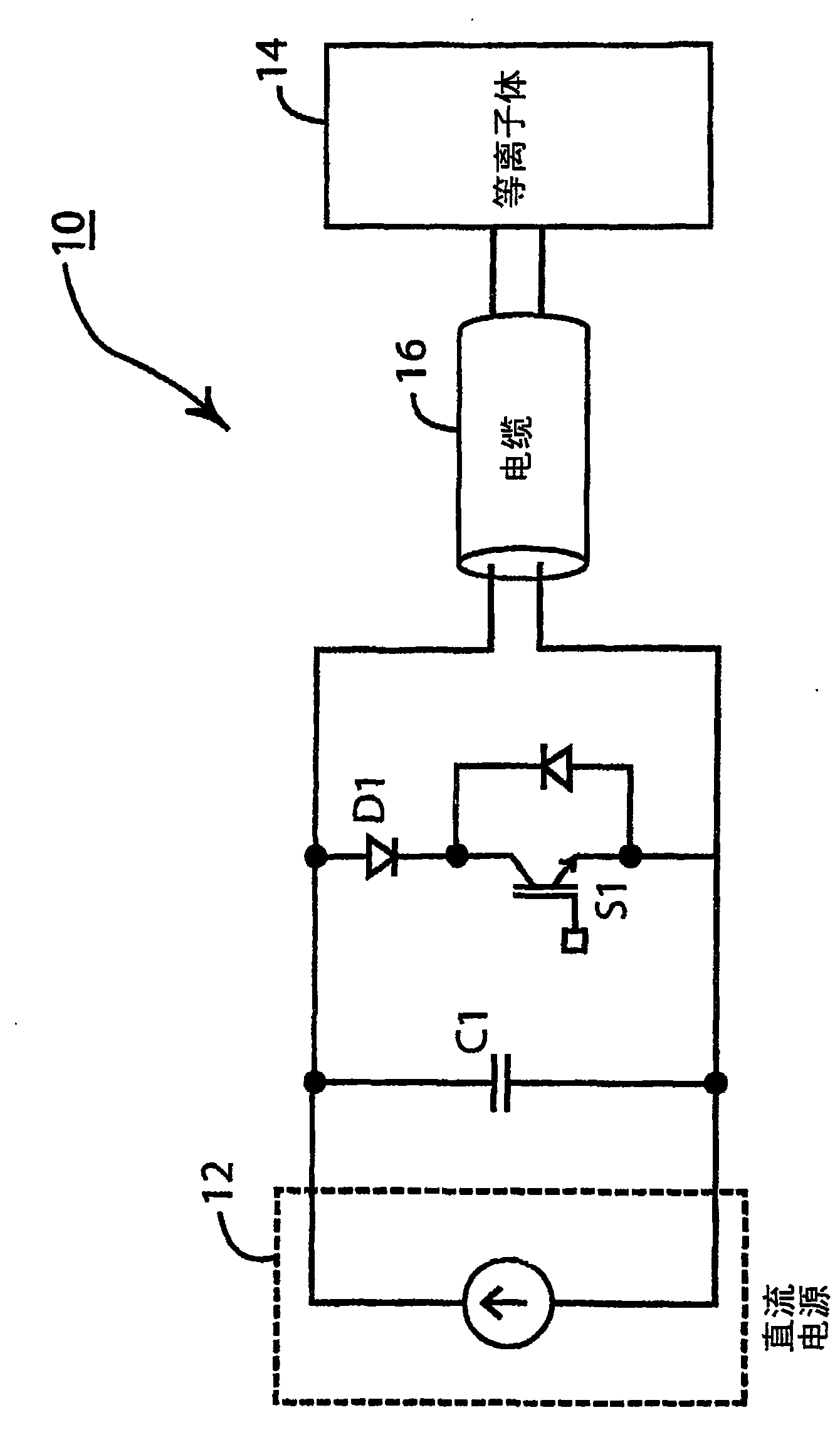

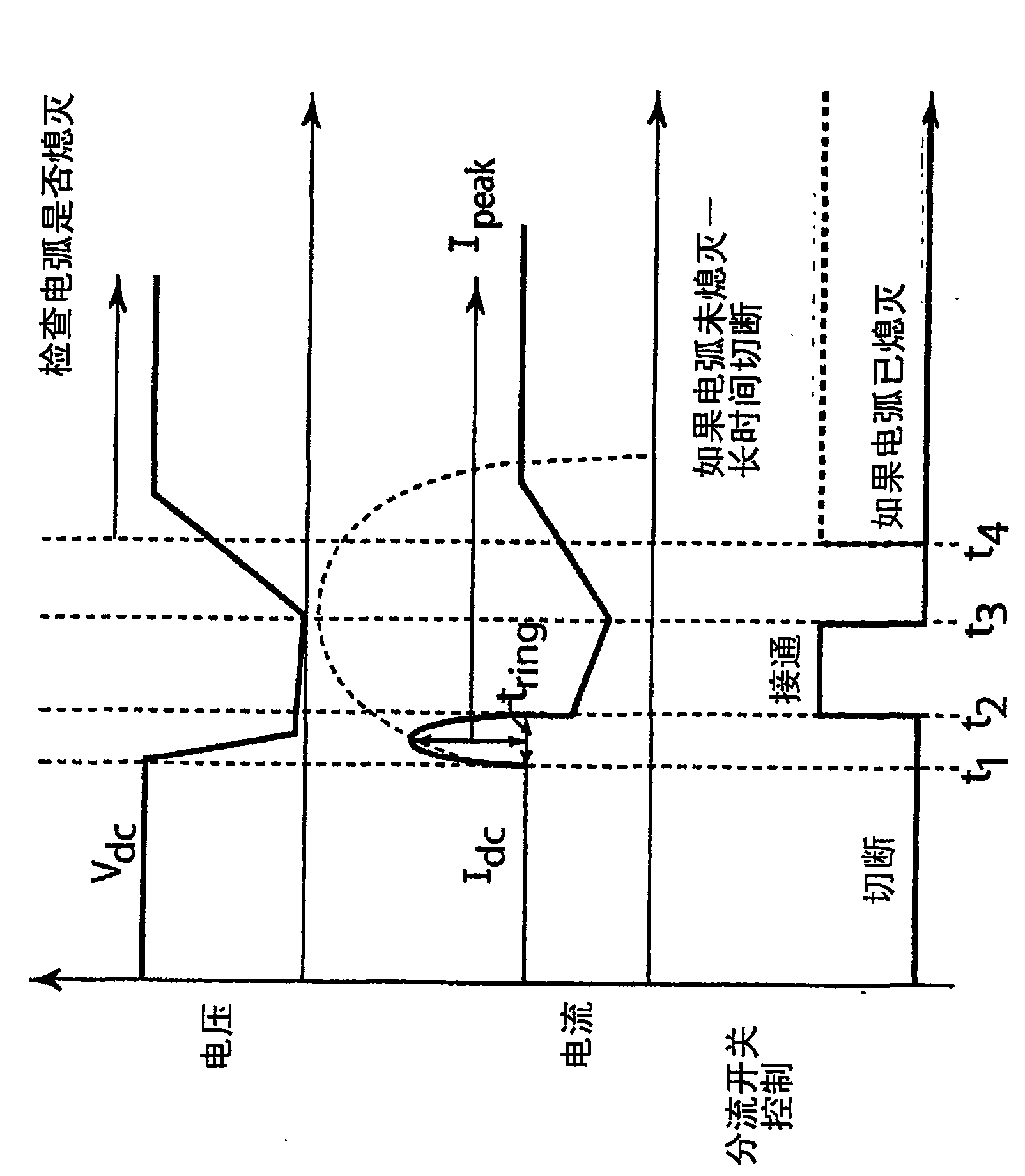

[0026] refer to figure 2 , which shows a DC plasma processing apparatus 10 embodying the principles of the present invention. A DC power source 12 supplies power to the plasma 14 via an electrical cable 16 . A plasma 14 is ignited between electrodes (not shown) and contained within a chamber (not shown) to treat a workpiece on a substrate (also not shown, but known to those skilled in the art). In parallel with the output capacitor C1 is a shunt switch S1. The shunt switches may be insulated gate bipolar transistors (IGBTs), field effect transistors (FETs), or other suitable semiconductor switches.

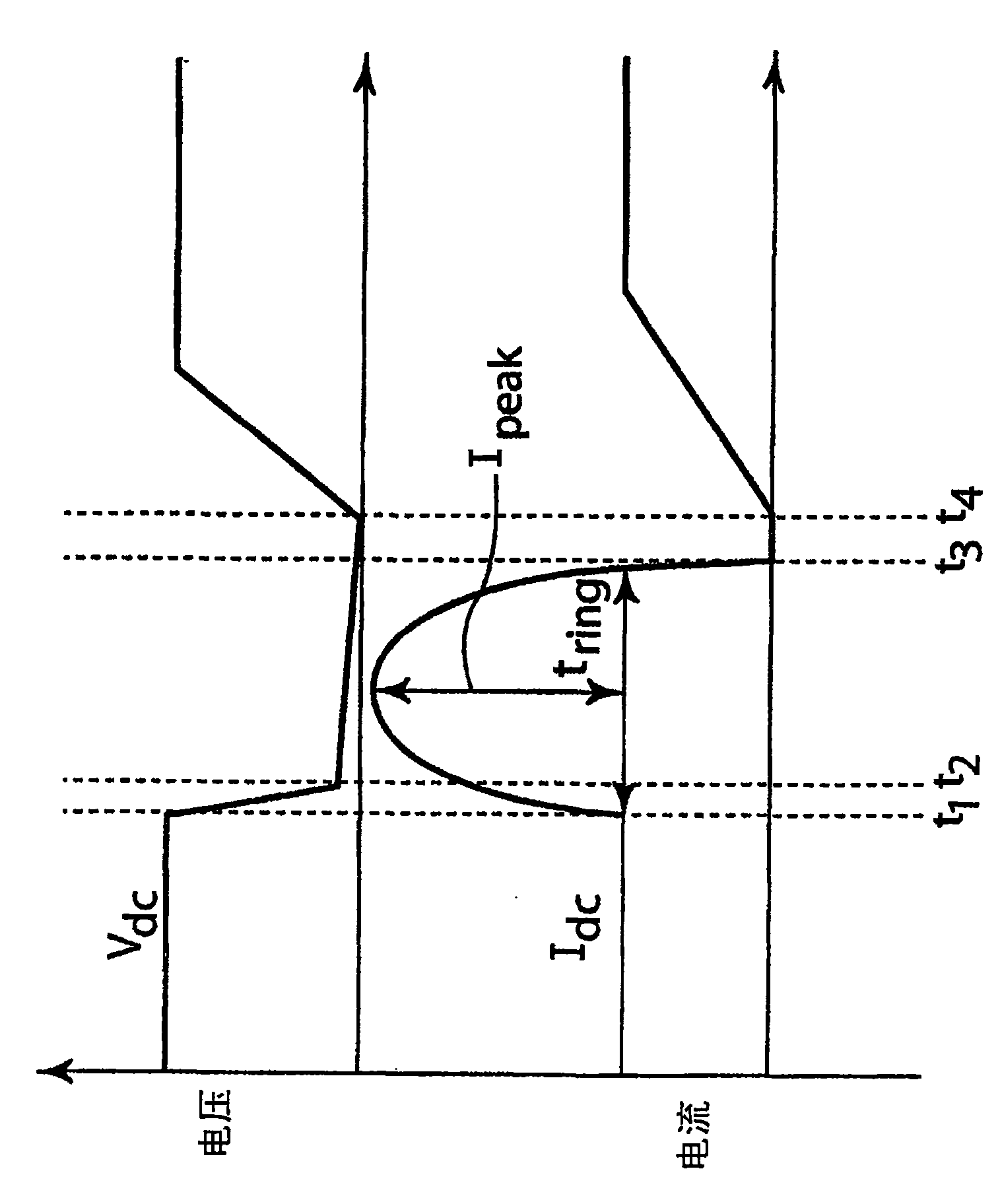

[0027] The DC power supply should be designed as an adaptive current source on the time scale of the arc so that the output current does not become excessive when the output voltage decreases due to arcing. A common way to achieve high adaptability in a DC power supply is to have a sufficiently large inductor in series with the output, or a current controller with fast current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com