Motor vehicle energy-saving process

A technology for motor vehicles and engines, applied in the direction of machines/engines, mechanical equipment, engine control, etc., to achieve the effect of eliminating the phenomenon of reverse drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

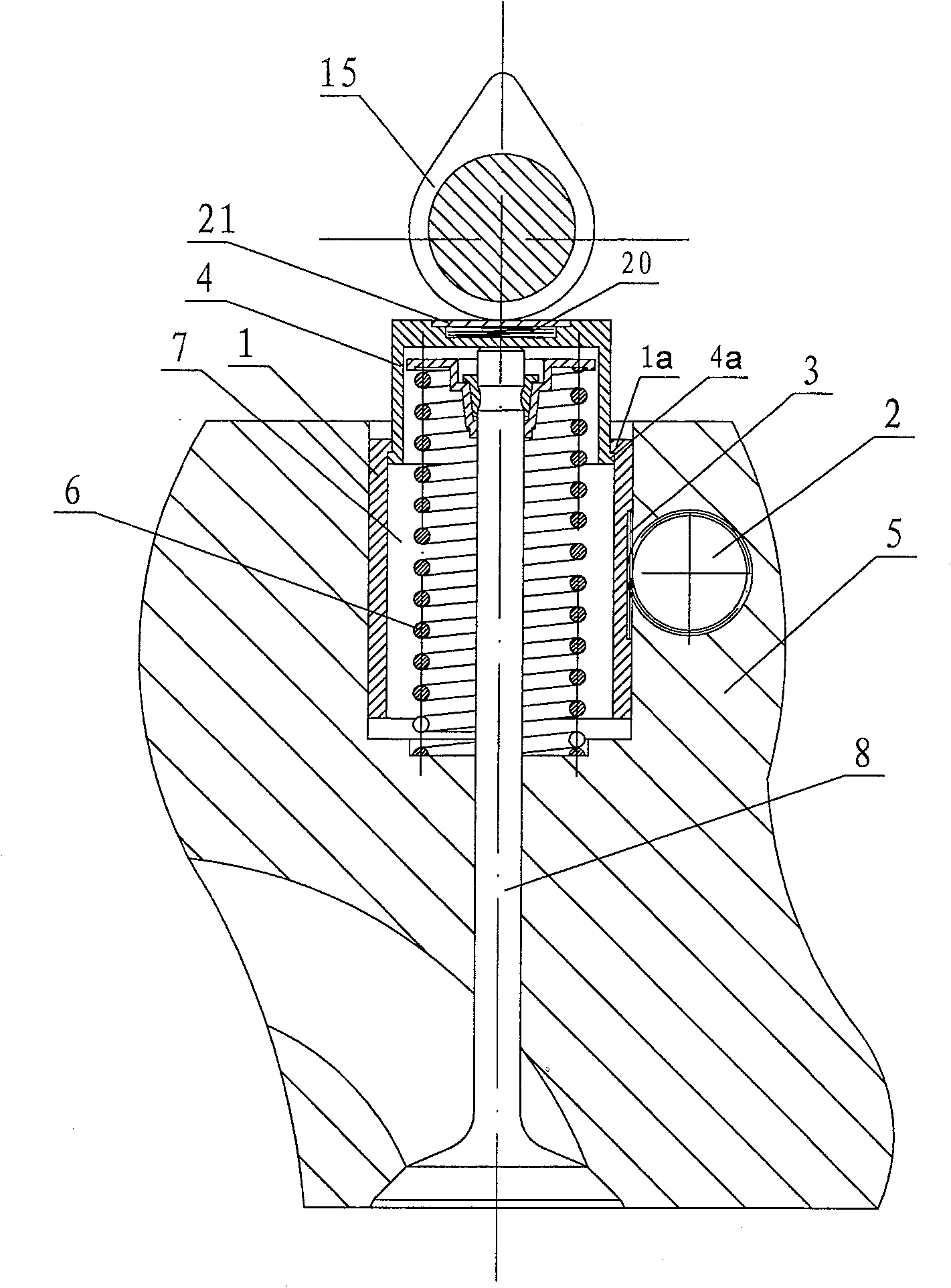

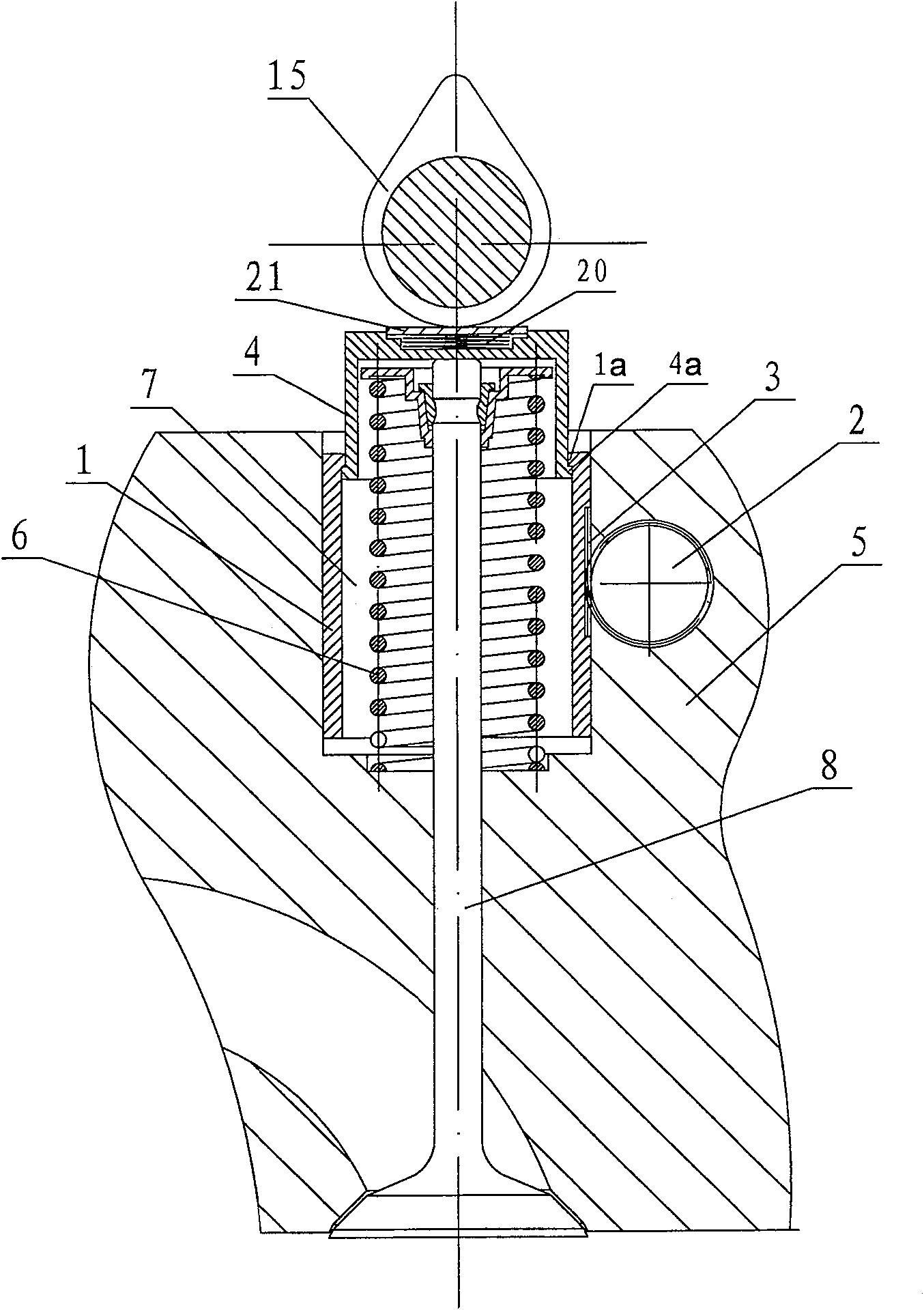

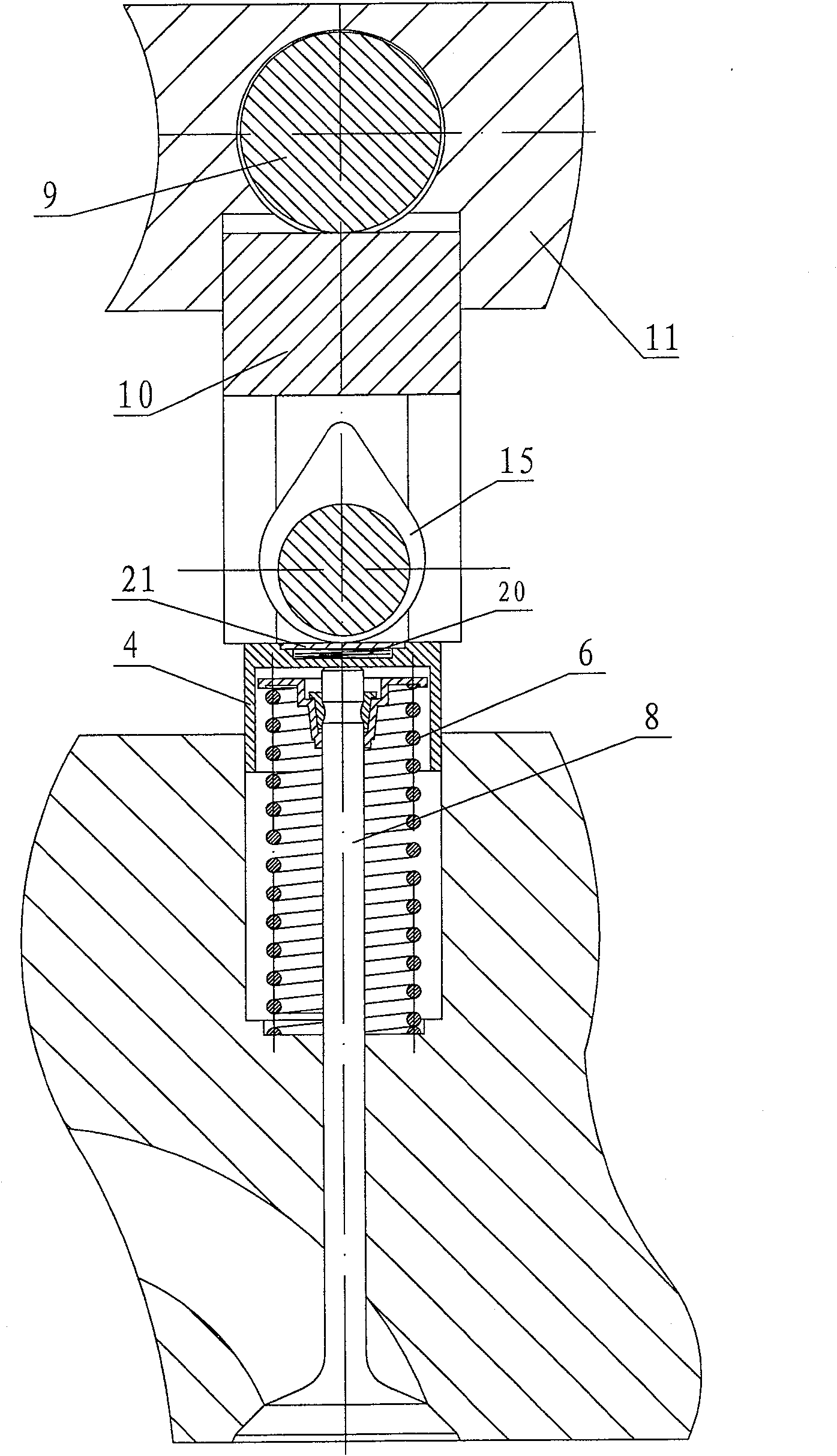

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] In order to realize the energy saving of the motor vehicle, the present invention is provided with an action mechanism in the engine. When the electric control system of the motor vehicle detects that the throttle is not supplied with oil and the engine is in the reverse drag working condition, an instruction is issued to make the action mechanism drive the valve stem toward the combustion chamber. direction to move a certain distance, so that the intake and exhaust valves cannot be completely closed. When the electronic control system of the motor vehicle detects that the throttle resumes fuel supply, brakes or the engine speed drops to close to idle speed, the action mechanism resets, and the valve stem is in the position of the valve spring. It is also reset under the action. The normal reciprocating movement of the valve stem under the action of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com