Glasses lens assembling system

A lens assembly and lens technology, used in installation, optics, instruments, etc., can solve the problems of reducing product yield and lens damage, and achieve the effect of improving yield, reducing damage rate, and maintaining uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further illustrate the present invention, the following preferred embodiments are given and described in detail in conjunction with the accompanying drawings.

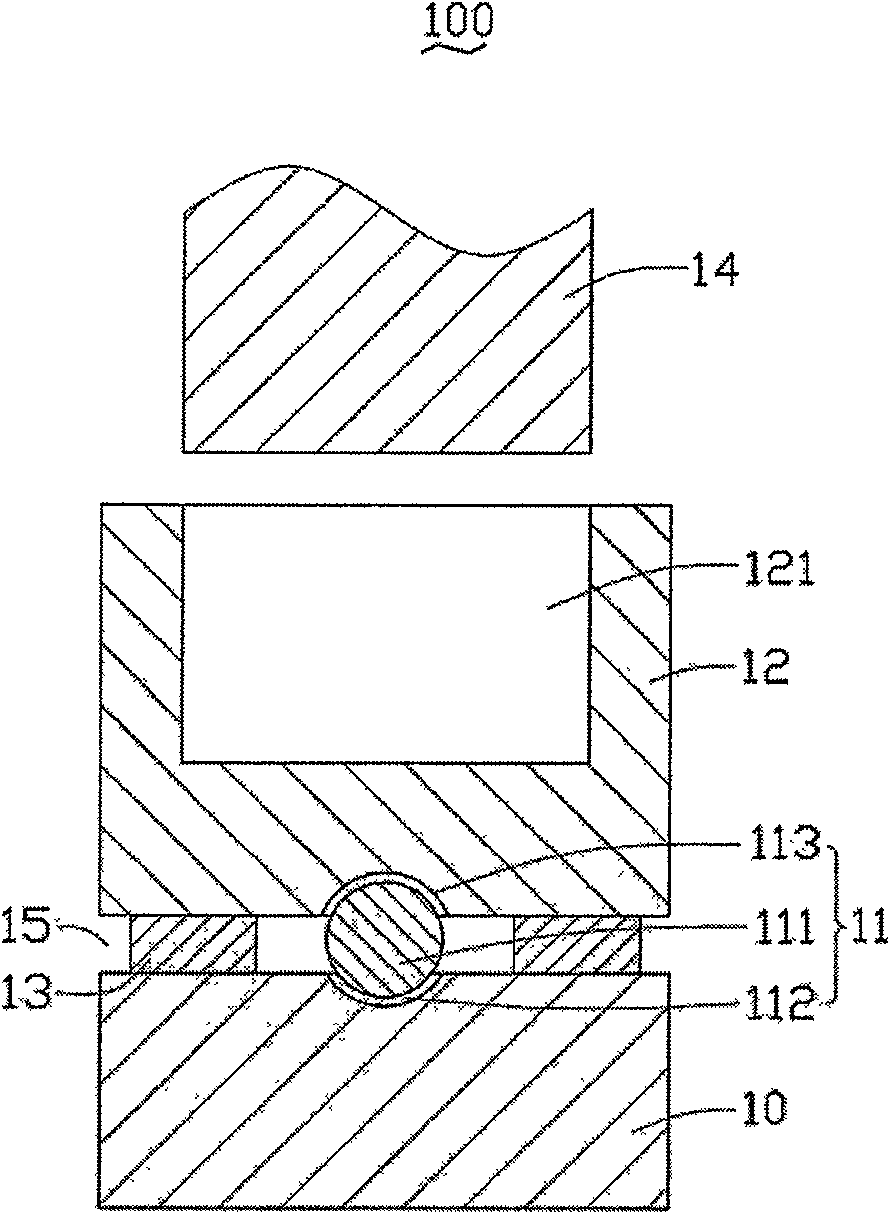

[0014] see image 3 As shown, the lens assembly system 100 provided by the first embodiment of the present invention includes a base 10, a universal joint 11 connected to the base 10, and a universal joint 11 connected to the base 10 through the universal joint 11. The lens seat 12, an elastic element 13 disposed between the base 10 and the lens seat 12, and a punch 14.

[0015] The base 10 is fixed on a machine platform (not shown) for supporting the lens holder 12 . The lens holder 12 has an accommodating cavity 121 for accommodating the lens to be assembled. The diameter and axial length of the accommodating cavity 121 are set according to requirements, for example, according to the diameter of the lens to be assembled and the thickness of the lens.

[0016] The universal joint 11 is disposed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com