Method for PU transfer printing and embossment one-step shaping for fabric, and device for using the said method

A printing device and fabric technology, applied in printing devices, printing of special types of printed matter, transfer printing, etc., can solve problems such as low rubbing fastness, poor light fastness and weather fastness, instability, etc., to improve production Effects on efficiency and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

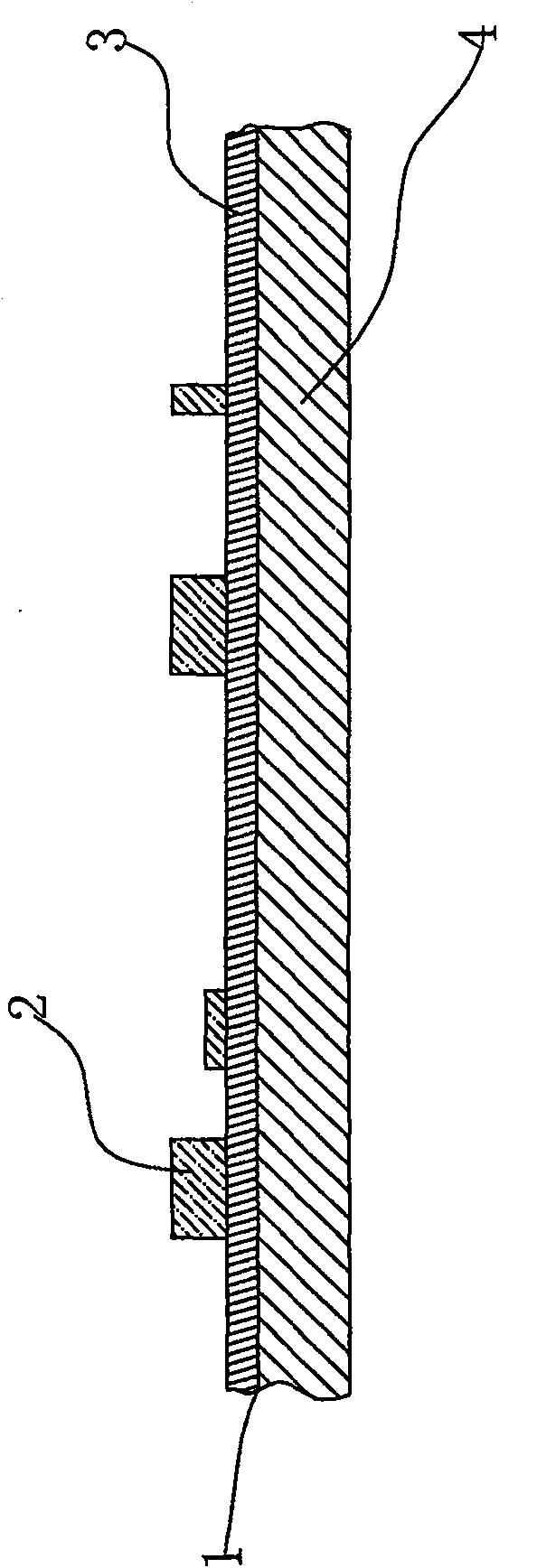

[0011] see figure 1 , the carrier 1 is the material that runs through the front and back in this method, it should have the performance of being able to be printed by PU paste, and it has plasticity when it is embossed, and it must have the PU pattern when separating the carrier 1 and the fabric after embossing and drying 2 is completely separated from the characteristics of carrier 1. It can be a polyester film 4 coated with a release agent 3 on the surface with a certain thickness, or a release paper with a certain strength, or other strips with release properties.

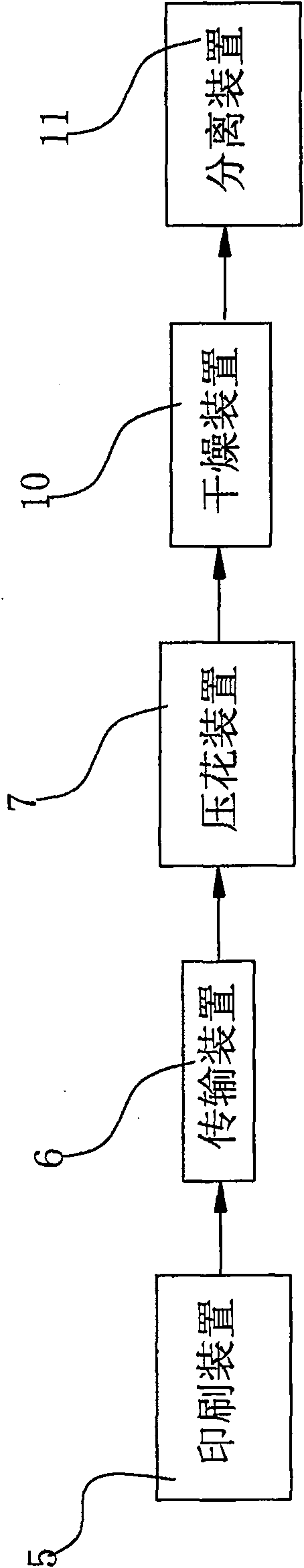

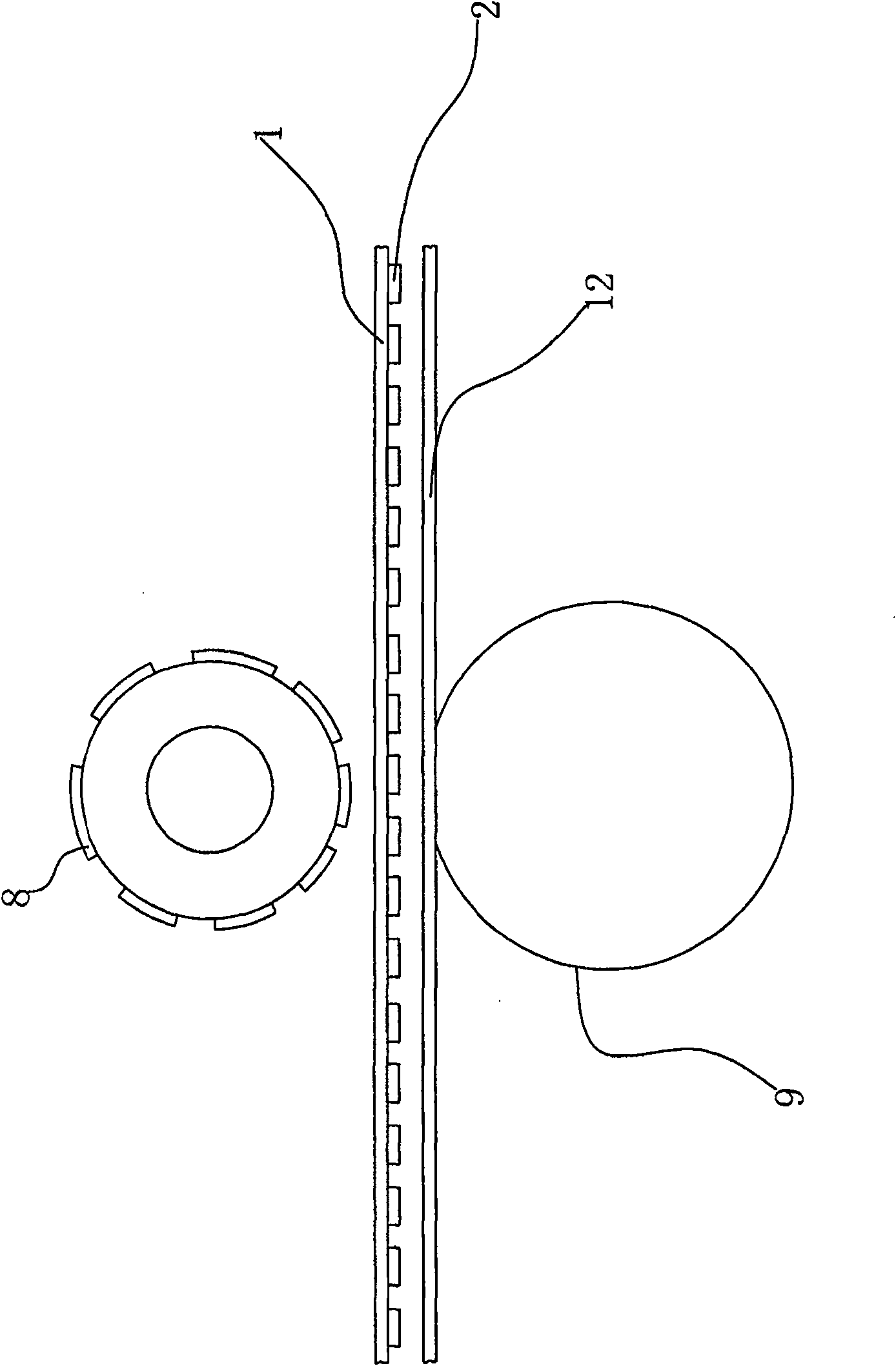

[0012] see figure 2 , image 3 PU paste is used as the printing medium. After the carrier 1 passes through the printing device 5, the surface of the carrier 1 has a designated printed multi-color PU pattern. flower position, and the pattern is facing the embossing pattern, and the fabric 12 to be printed is introduced into the embossing device 7 at this time, and is pressed together with the carrier 1. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com