Controllable eddy burner

A burner and combustion chamber technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems that the combustion temperature cannot be well controlled, stable combustion cannot be achieved, and tempering can be avoided, so as to avoid the phenomenon of tempering or defiring , good fuel adaptability and wide fuel adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

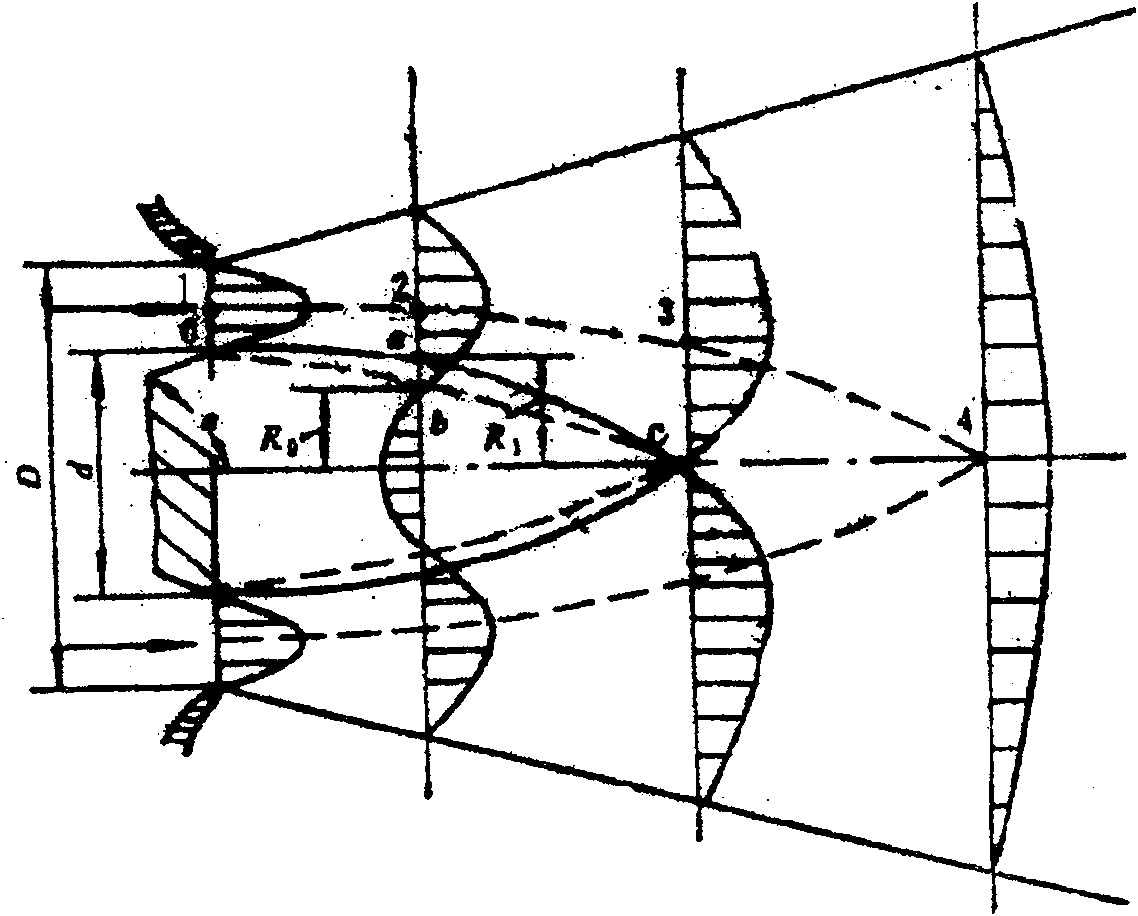

[0020] According to the basic principles of fluid mechanics, the flow of non-streamlined objects in the jet is called blunt body flow. figure 1 Shown is a schematic of the wake flow of a bluff body. When the jet bypasses the bluff body, a deceleration and diffusion flow area is formed in the flow field downstream of the bluff body, and in the wake area of the bluff body, due to the retardation of the bluff body, the fluid separates from the boundary layer and forms a low-pressure area. Under the action of the pressure gradient, a recirculation vortex region is formed in the wake region of the blunt body, and there is a strong exchange of momentum, heat and mass between the recirculation region and the mainstream region. After the main jet bypasses the recirculation zone, it converges at point c, and the maximum velocity on the jet section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com