Measurement method for enhancing tunnel lateral direction penetrating accuracy

A measurement method and precision technology, applied in the field of measurement of tunnel construction, to achieve the effects of improving precision, high orientation precision, and avoiding low positioning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

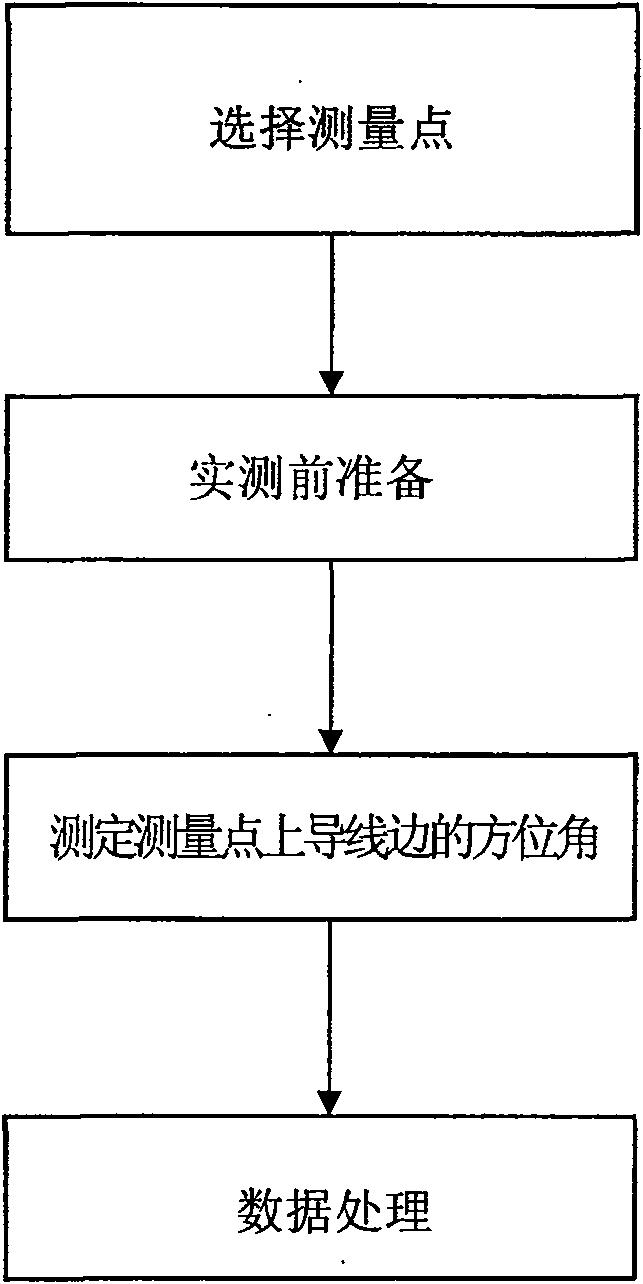

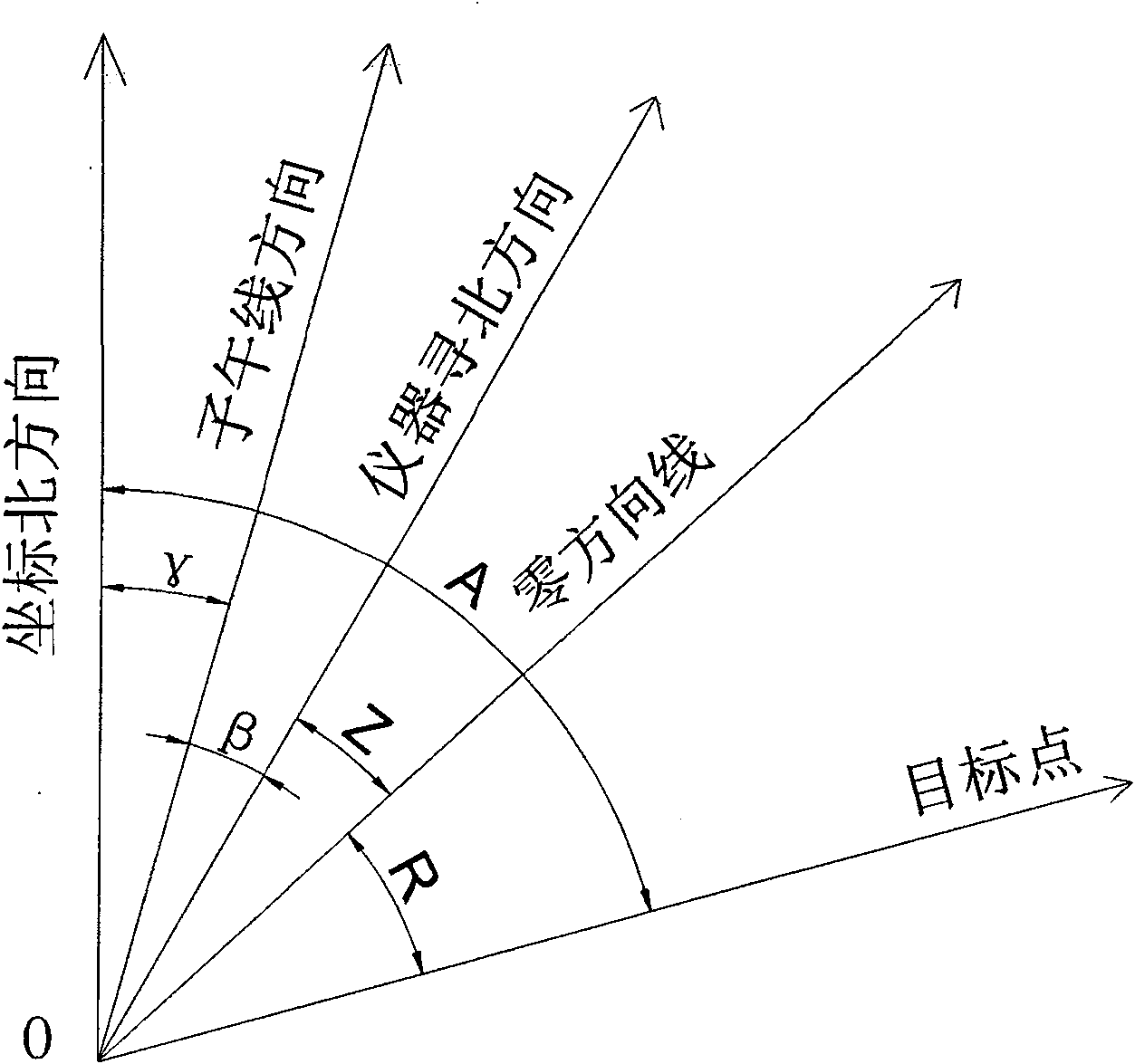

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments.

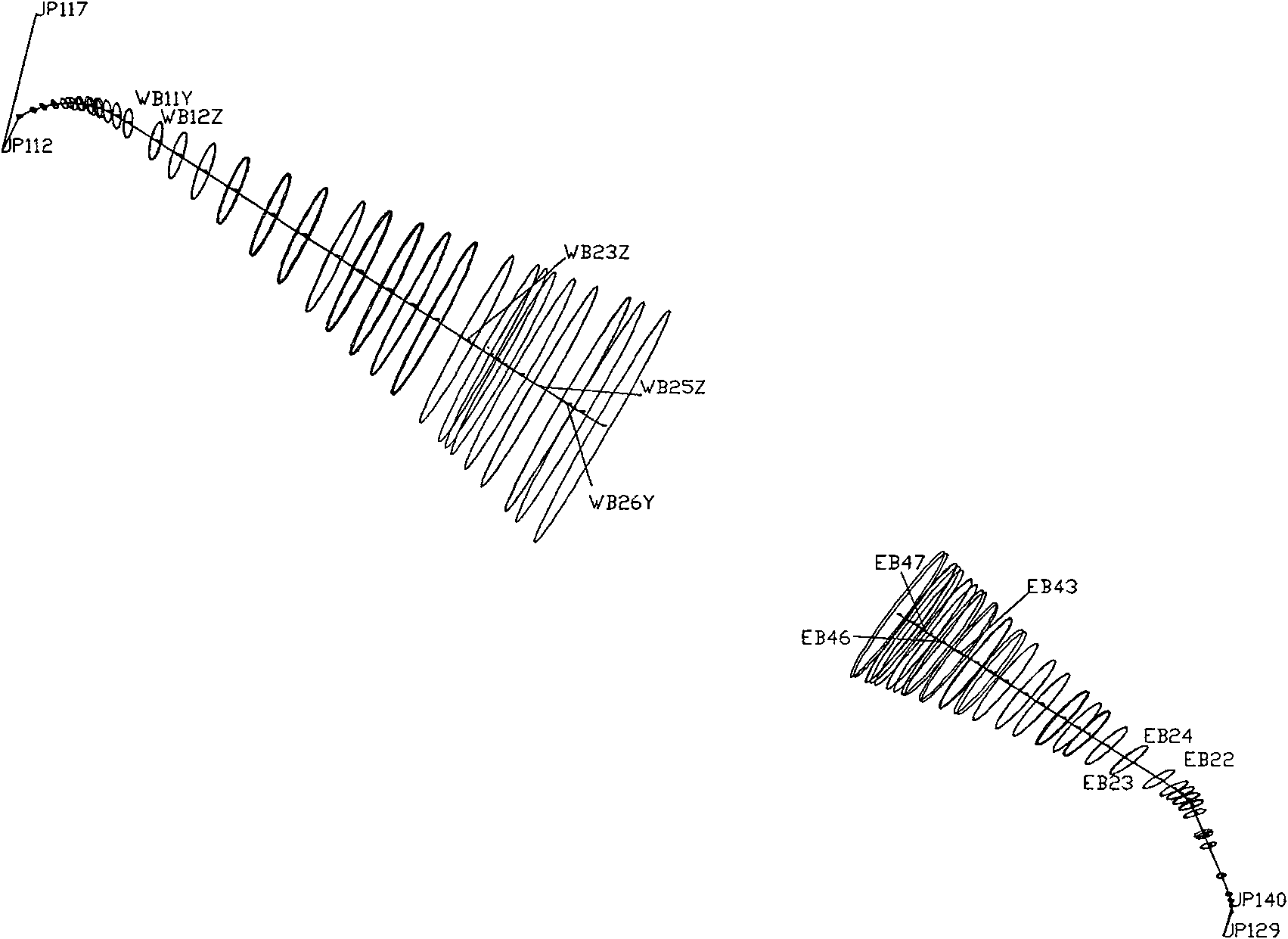

[0025] See first image 3 , the figure shows the measuring wire of a 17.5km long tunnel, the wire is divided into east and west ends, EB is the control point inside the tunnel at the east end, WB is the control point inside the tunnel at the west end, JP is the control point outside the tunnel at the east end and west end point. According to the technical design book, the TCA2003 total station produced by Swiss Leica Company is used to automatically observe and record the wire edges and angles. For direction observation, 12 rounds are observed according to the design requirements of the second-class conductor technology, and the error in angle measurement is 1 second; for side length observation, each side is round-trip measured for 1 period, and each period is measured for 4 rounds. According to the angle measurement error of 1 second, the distance measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com