Method for improving air compressor blade load by using pumping and sucking

A compressor and load technology, which is applied in the design of compressor blades and high-load fans, can solve the problems that the blade load cannot be increased, the loss coefficient can be reduced, and the gas cannot be used, so as to improve the resistance to separation, increase the blade load, Eliminate the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

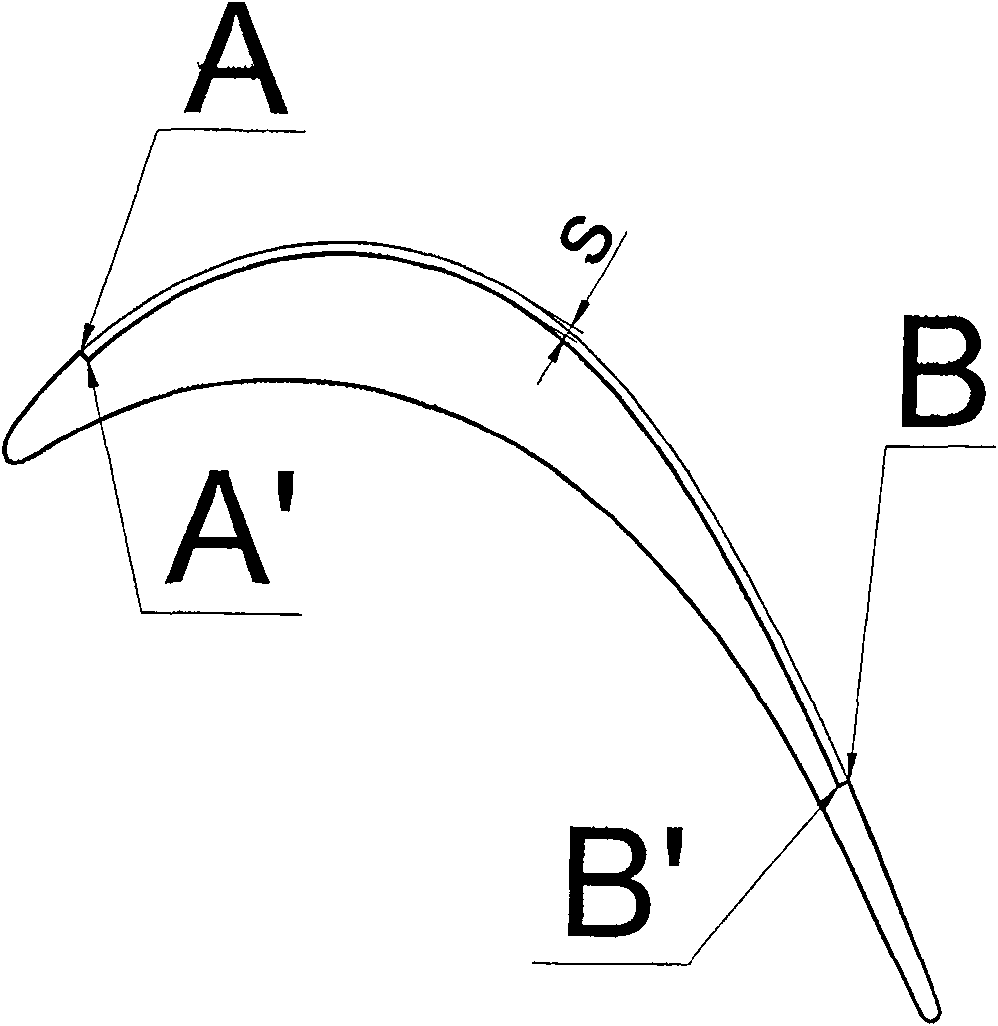

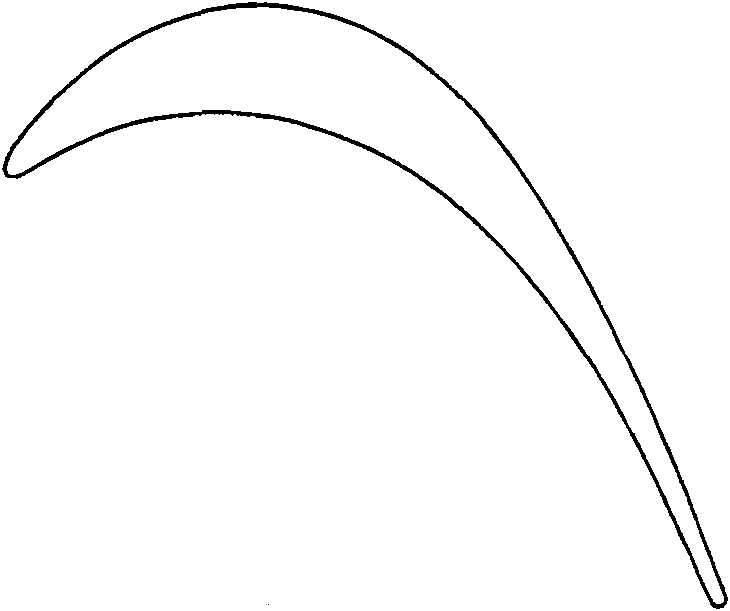

[0029] Taking the NACA0012 airfoil as an example, considering the thin trailing edge of the airfoil, the middle and rear part of the airfoil is thickened according to the requirements of the processing technology and other aspects of the method of controlling the boundary layer by blowing and sucking air. The middle arc adopts a circular arc, and the comparison diagram of the blade shape before and after the modification is as follows figure 1 , where the dotted line shows the prototype. The consistency of the cascade is 0.87, the bending angle of the blade shape is 60 degrees, and the chord length of the blade is 113.2mm.

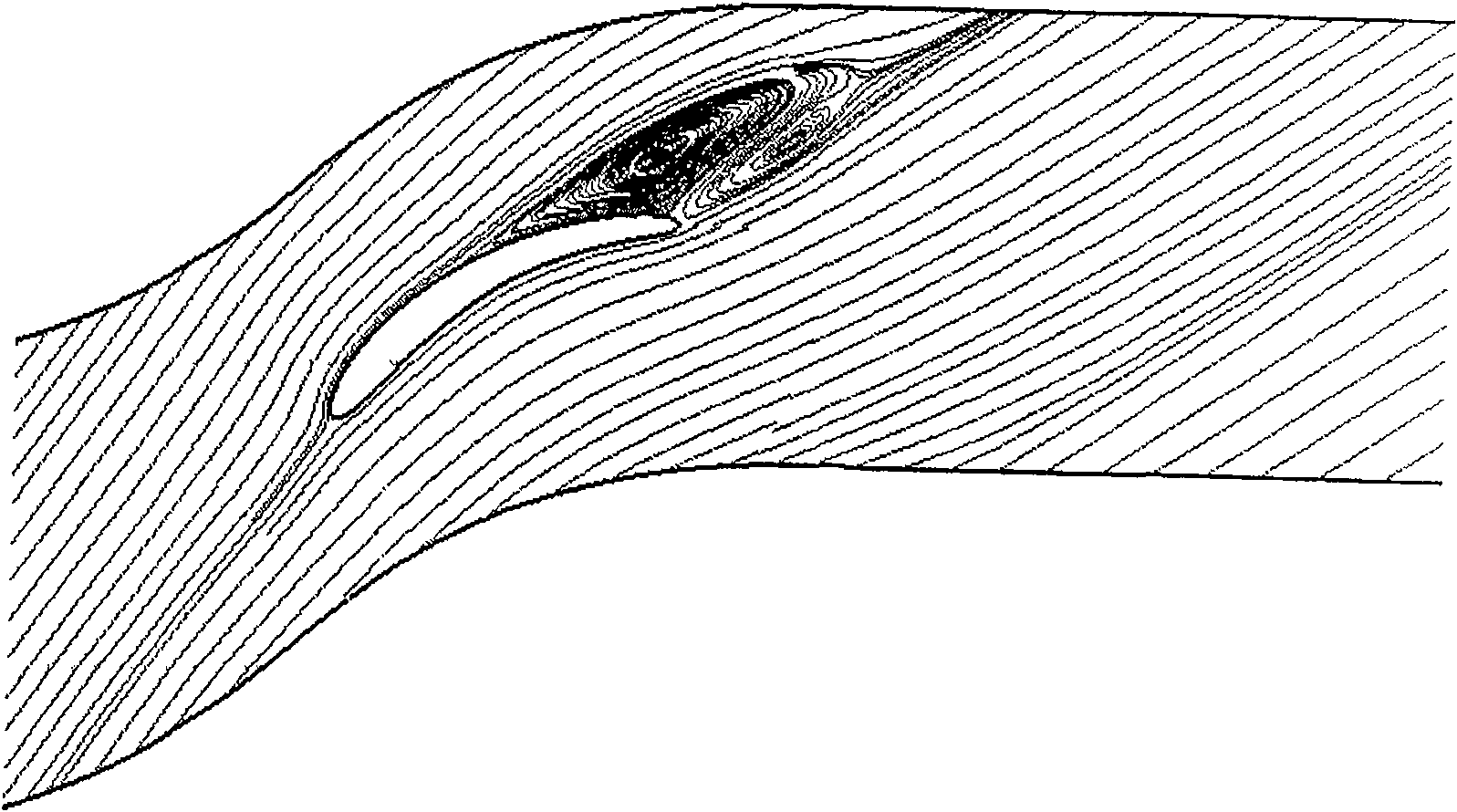

[0030](1) Calculate the flow field of the cascade according to the geometric parameters of the blade surface, such as the cascade consistency, blade bending angle and blade chord length, etc., and obtain the Mach number distribution curve of the blade back, and determine the suction peak position of the blade back according to this curve, that is, figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com