A Tension Structure for Reducing Disturbance Loss

A technology of rib structure and rib, applied in the direction of blade supporting elements, engine elements, machines/engines, etc., can solve the problems of reducing the operating efficiency of turbomachinery, increasing the additional mass of the blade, affecting the safe operation of the blade, etc., so as to improve the safety Effect of running margin, reducing added mass, reducing angle of attack loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

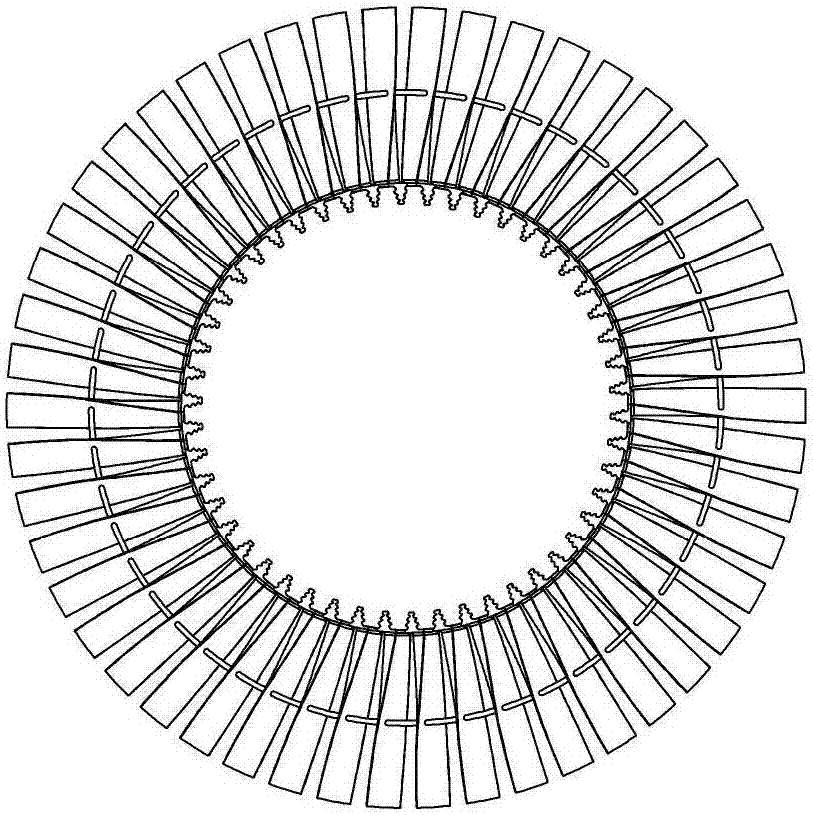

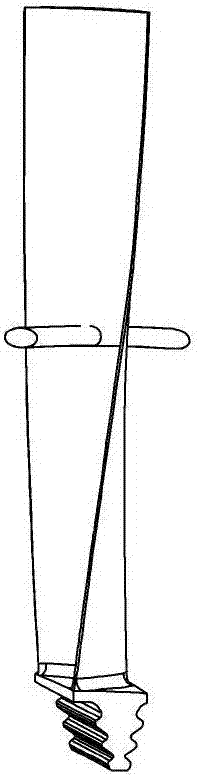

[0024] refer to figure 1 , figure 2 As shown in Fig. 1, the structure of the rotating damping vane with damping ties and the structure of a single damping vane are given respectively. The damping blade includes a blade body, a blade root and a damping tendon structure.

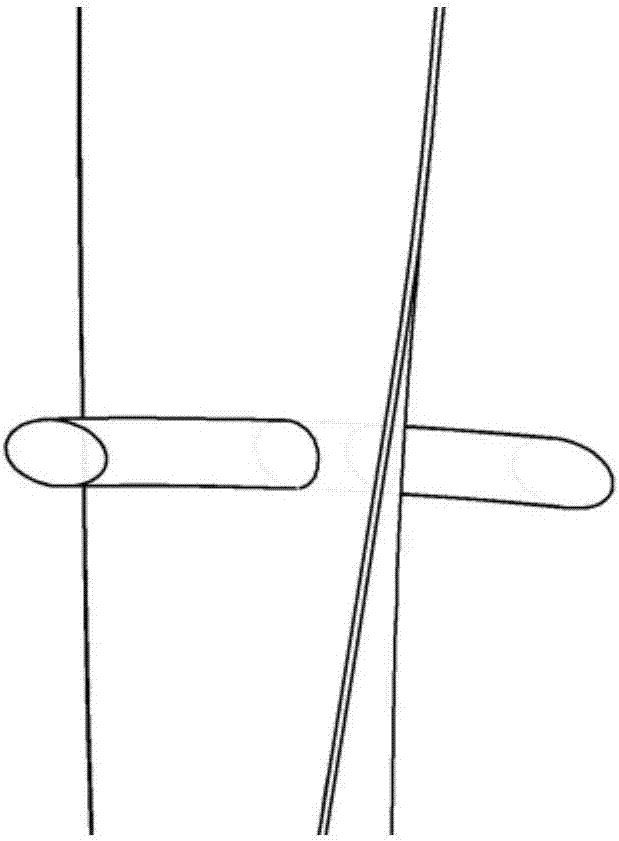

[0025] refer to Figure 3a , Figure 3b As shown, the conventional damping tendon structure and the damping tendon structure of the present invention are respectively provided. The invention provides a wedge-shaped or rectangular channel on the basis of the conventional damping tendon structure. The main airflow flows downstream through the tendons, and another small part of the airflow passes through the wedge-shaped or rectangular channels of the tendon structure, and merges into the main flow by means of synthetic jets, so as to inject high-energy fluid into the tail low-energy fluid area around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com