Low-temperature dry and wet circulating erosion device

A dry-wet cycle and low-temperature technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of large human error and low research efficiency, achieve low cost, easy production and operation, and improve research Effects of Efficiency and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

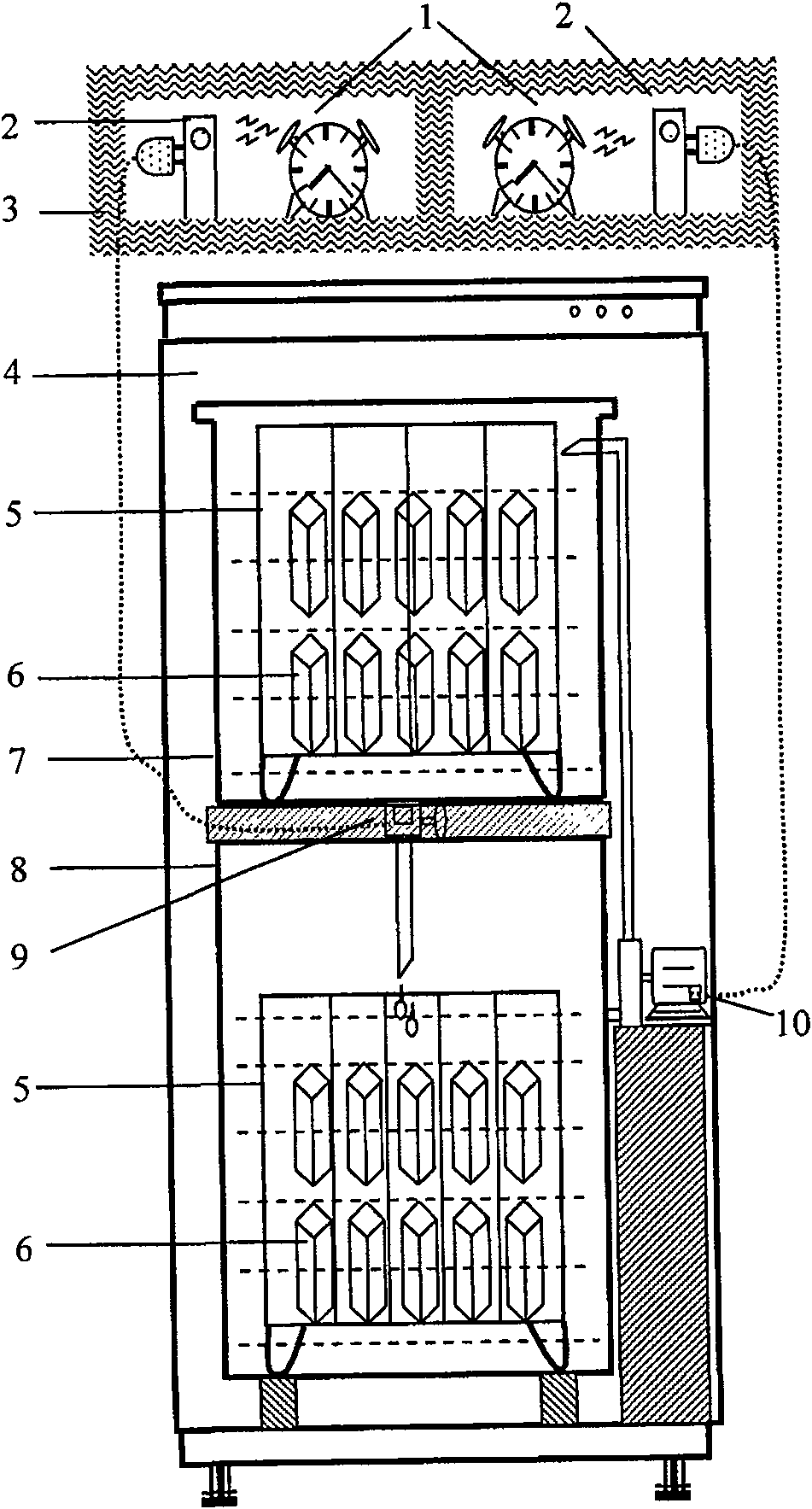

Embodiment 1

[0020] Embodiment 1: Adopt commercially available timing alarm clock 1 and sound-activated delay switch 2, delay time is 2 minutes, load power 20W-200W; Adopt 5cm thick polystyrene board to make sound-proof sealing box 3, adopt commercially available 220L Refrigerated box 4, adopt stainless steel Saijo to make basket 5, adopt transparent plastic box as upper corrosion solution tank 7 and lower corrosion solution tank 8, adopt commercially available electronic valve 9 and water pump 10, water pump head is 5m, power 120W, the above-mentioned Device according to figure 1 Assemble as shown. Among them, two sets of timing alarm clocks 1 and voice-activated delay switches 2 are respectively placed in different sound-proof sealed boxes 3, the power supplies of the electronic valve 9 and the water pump 10 are respectively connected to the two voice-activated delay switches 2, and the two baskets 5 respectively placed in the upper erosion solution tank 7 and the lower erosion solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com