Abrasive band machine

An abrasive belt machine and abrasive belt technology are applied in the field of abrasive belt machines, which can solve the problems of wire breakage and increase the risk of short circuit, and achieve the effects of simple operation, comfortable operation and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

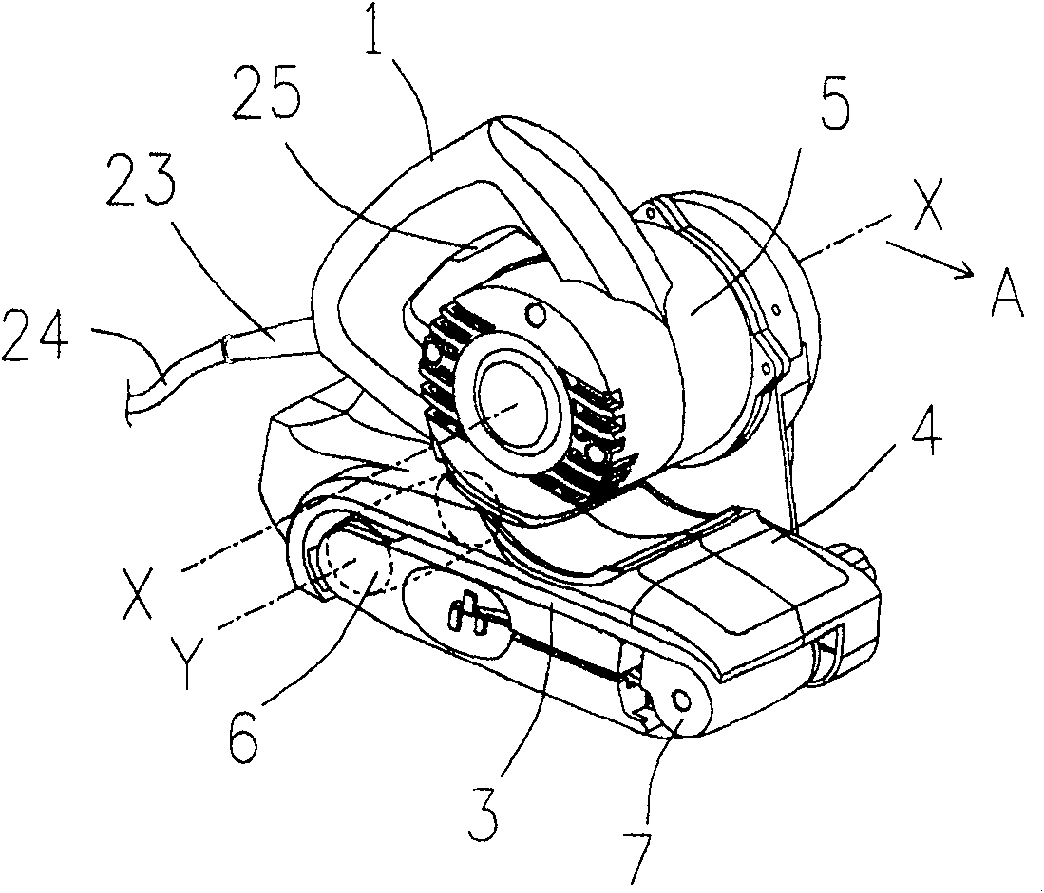

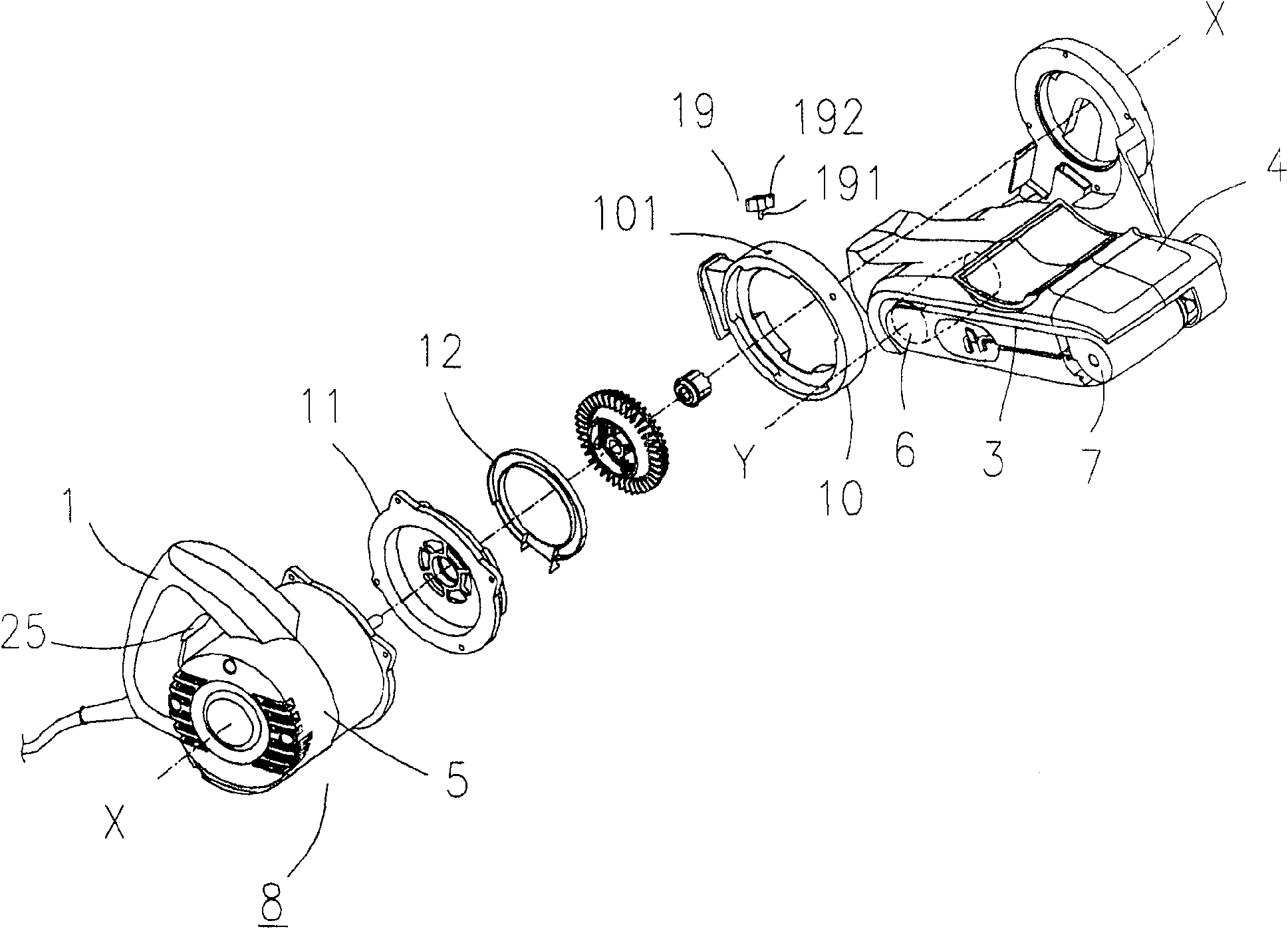

[0019] See attached Figure 1~6 , the present invention discloses a belt machine, comprising a handle 1, a motor 2, an abrasive belt 3 for sanding workpieces, an abrasive belt housing 4, a motor housing 5, a driving wheel 6, and a driven wheel 7.

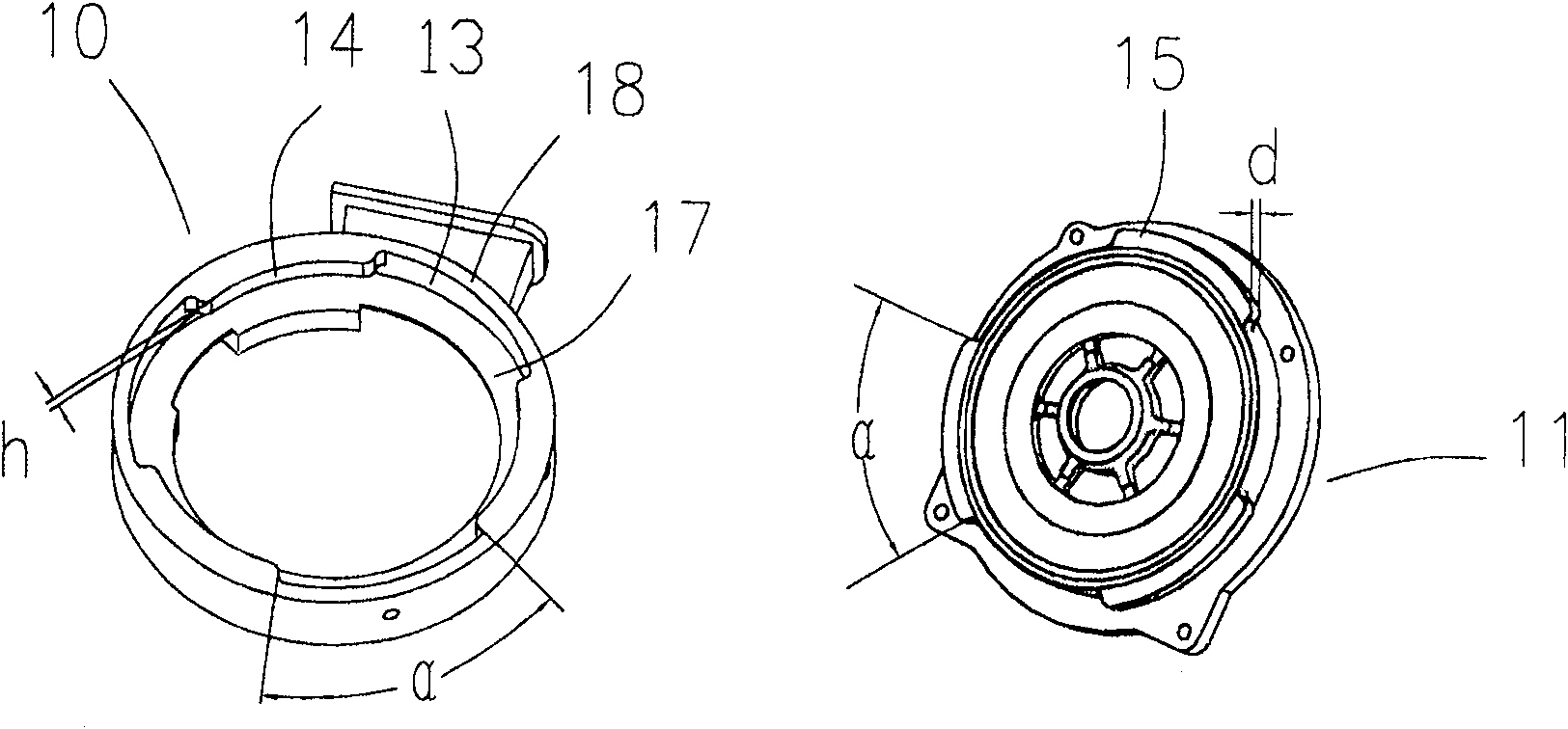

[0020] The abrasive belt 3 is annular, and connects the driving wheel 6 and the driven wheel 7 . The driving wheel 6 has a longitudinal axis Y. The motor 2 is accommodated in the motor housing 5, the motor 2 has a motor shaft 21, the motor shaft 21 defines a longitudinal axis X, the longitudinal axis X of the motor 2 is parallel to the driving wheel The longitudinal axis Y. One end of the motor shaft 21 is connected with a gear 22 , and the gear 22 drives the driving wheel 6 to rotate through a transmission device 16 , thereby driving the driven wheel 7 to rotate through the abrasive belt 3 . The abrasive belt 3 , the driving wheel 6 , the driven wheel 7 and the transmission device 16 are all arranged in the abrasive belt housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com