Even distribution type electrode component

An electrode assembly, uniformly distributed technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of low purification efficiency, electrodes are easily polluted by dust particles, etc., and achieve long cleaning time, simple structure and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

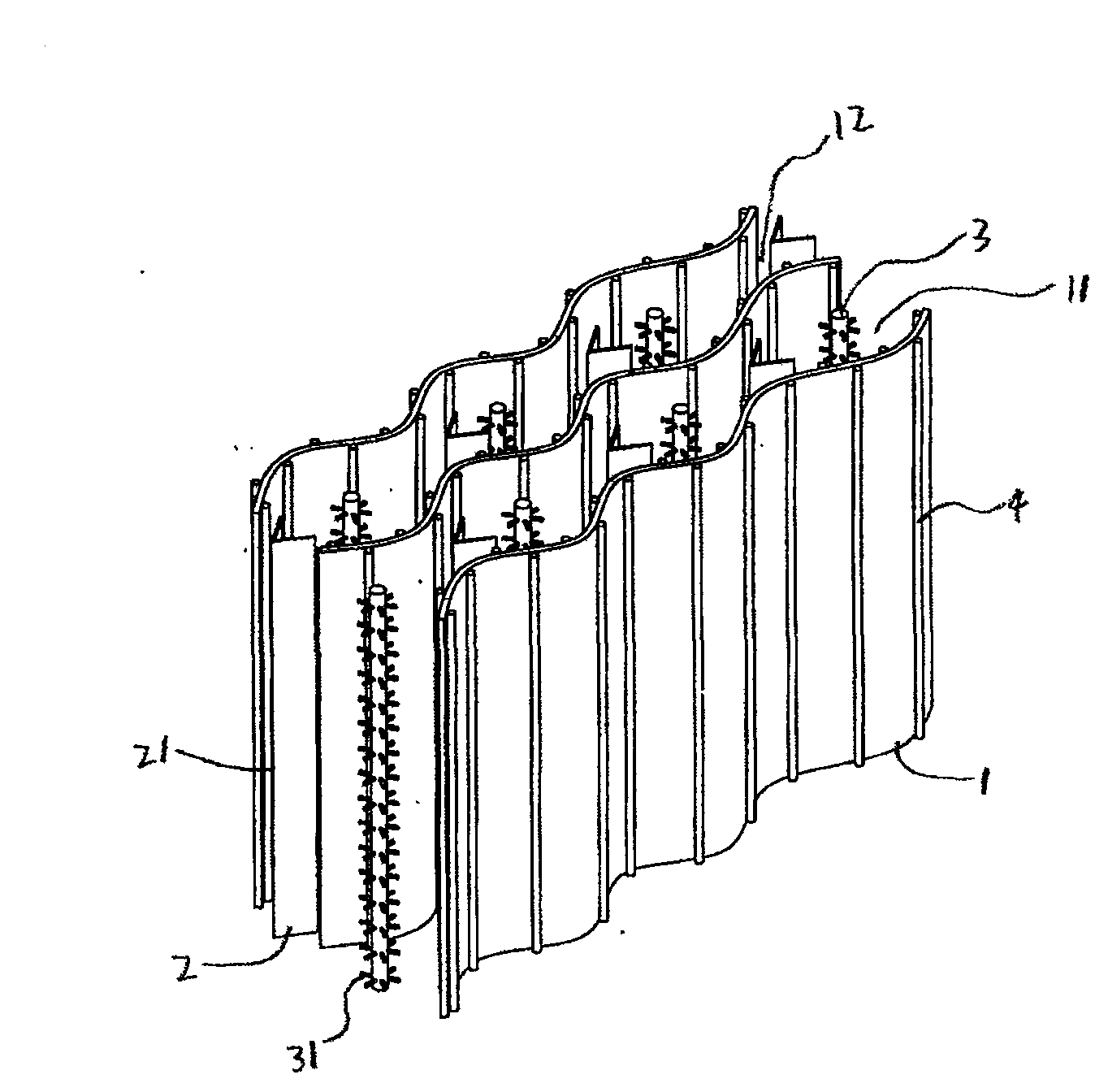

[0012] see figure 1 , which shows the appearance structure of an embodiment of the uniformly distributed electrode assembly proposed by the present invention. The electrode assembly includes a corrugated arc-shaped dust collecting plate 1 , a deflector plate 2 , an electrode 3 and an insulating protruding strip 4 .

[0013] There can be multiple arc-shaped dust collecting plates 1 according to the size of the electrostatic precipitator or device. The arc-shaped dust collecting plates 1 are arranged parallel to each other and symmetrically, so that two adjacent arc-shaped dust collecting plates 1 can form an arc-shaped dust-collecting area 11 which is approximately circular and a diversion area 12 whose cross-section is similar to a hyperbola. Adopting the structure of the arc-shaped dust collecting plate 1 can improve its strength on the one hand, and no deformation will occur when the dust on the arc-shaped dust-collecting plate 1 is cleaned by shaking, on the other hand, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com