Gas suction grappling bucket

A grab bucket and air suction technology, applied in vacuum cleaners, load hanging components, cleaning equipment, etc., can solve the problems of surrounding environment pollution, large dust, unreasonable design, etc., and achieve the effect of improving the environment and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

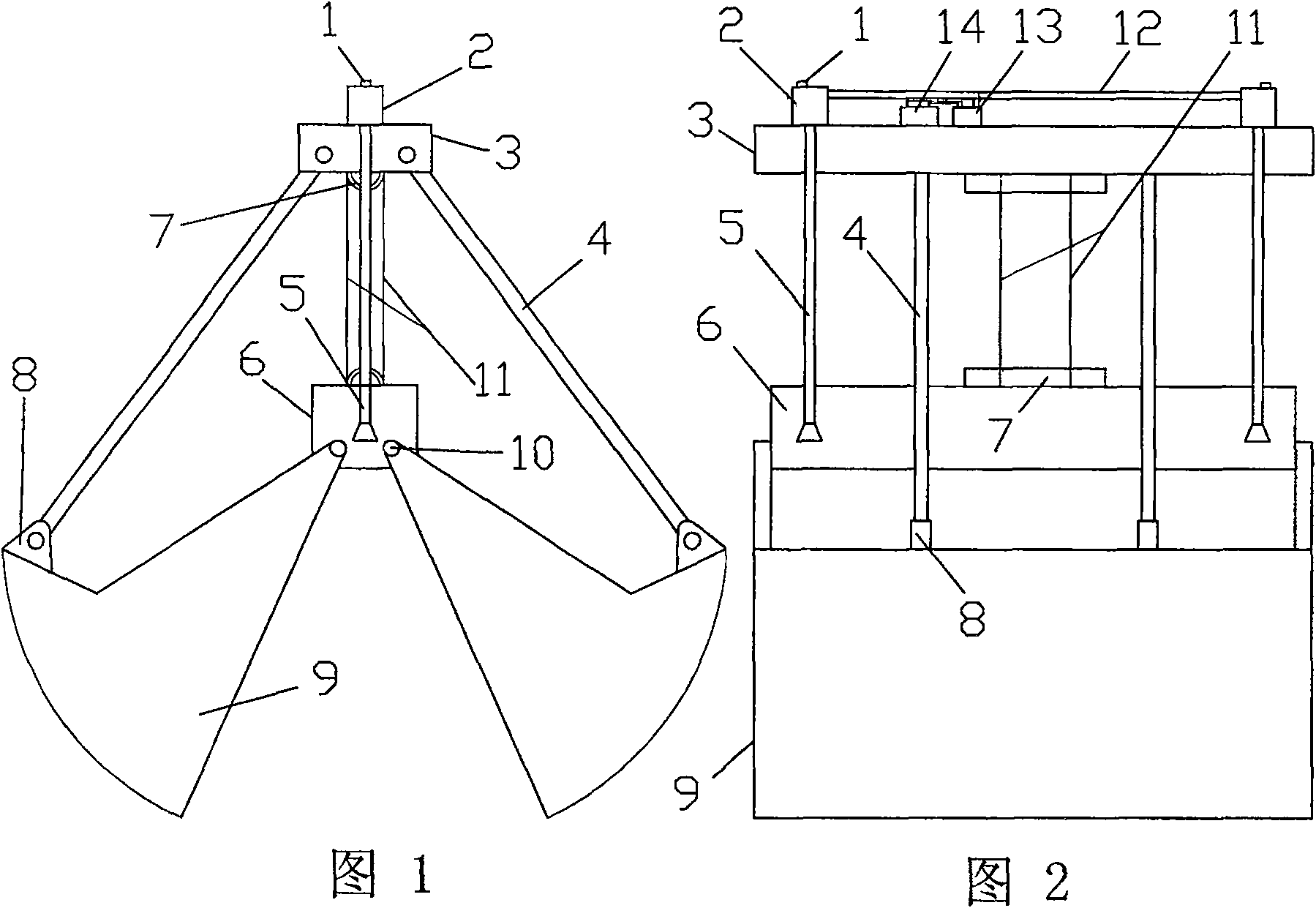

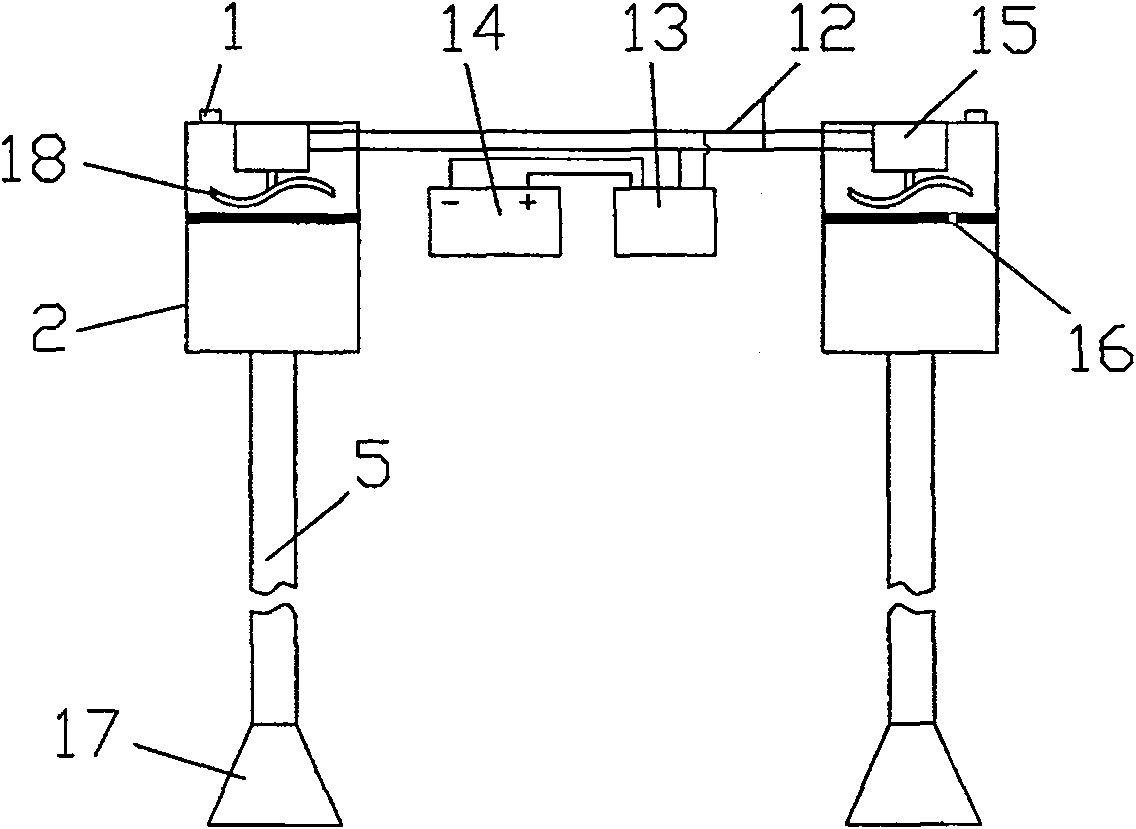

[0010] The invention relates to a grab bucket for loading and unloading bulk materials. Its structure includes a grab bucket main body and a dust suction device connected with the grab bucket main body, which constitute an air suction grab bucket.

[0011] The following combines examples and Figure 1 to Figure 3 The present invention is further described.

[0012] The structure of the air suction grab provided by the present invention is the same as that of the prior art, mainly including upper beam 3, support rod 4, lower beam 6, pulley 7, lug 8, jaw plate 9, hinge shaft 10, steel wire rope 11.

[0013] In the air suction grab provided by the present invention, the dust collection device is a remote control dust collection device. This dust suction device mainly is made up of bellows 2, control box 13, accumulator 14, and they are fixedly contained on the upper beam 3. A suction pipe 5 is connected to the bottom of the bellows 2, and the lower end of the suction pipe exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com