A dust-free polishing device for metal products

A technology for metal products and polishing devices, applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of complex equipment, high requirements on assembly and site, hidden safety hazards, etc., to reduce polishing The effect of pressure, reducing polishing strength, accelerating plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

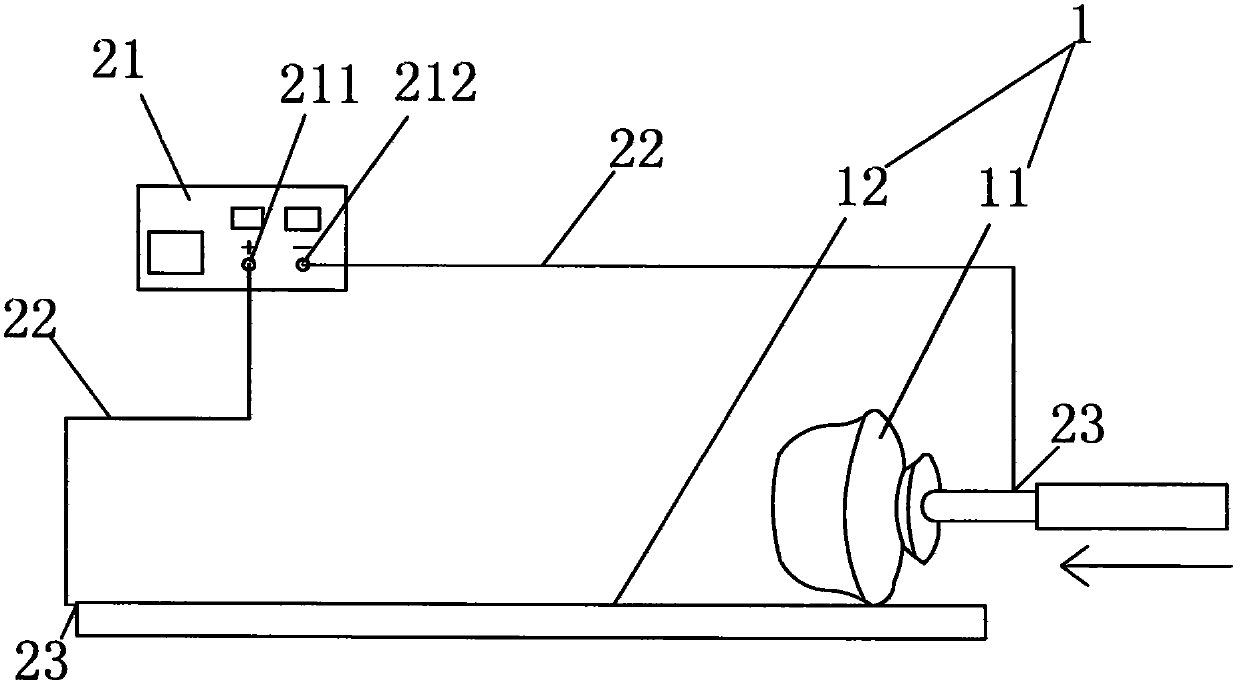

[0027] see figure 1 As shown, a dust-free polishing device for metal products includes a polishing system 1 and a set of weak current loop circuit systems 2;

[0028] The polishing system 1 includes a conductive manual polishing grinding wheel 11 and a metal product 12 to be processed, both of which constitute a pair of friction pairs;

[0029] The weak current loop circuit system 2 includes a weak current power supply 21, two wires 22 respectively connected to the positive pole 211 and the negative pole 212 of the weak current power supply 21, and a corresponding number of power connectors 23;

[0030] One end of a lead 22 is connected with the positive pole 211 of the weak point power supply 21, and the other end of the lead 22 is connected with the electric head 23, and one end of the other lead 22 is connected with the negative pole 212 of the weak point power supply 21, and the lead 22 The other end is connected with a power connector 23; the two power connectors 23 are ...

Embodiment 2

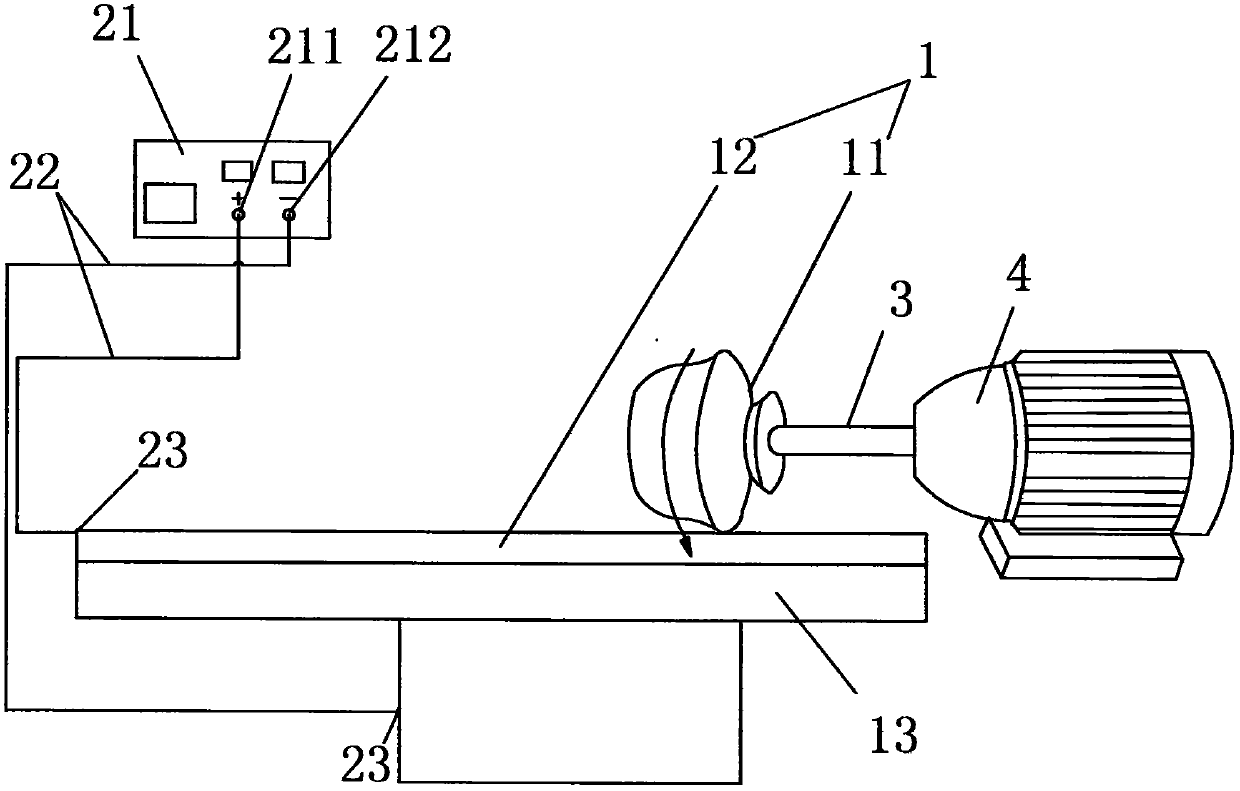

[0034] see figure 2 As shown, a dust-free polishing device for metal products includes a polishing system 1 and a set of weak current loop circuit systems 2;

[0035] The polishing system 1 includes a conductive polishing wheel 11, a metal product 12 to be processed, and a conductive fixed tool 13 for fixing the metal product 12 to be processed. The conductive polishing wheel 11 and the metal product 12 to be processed fixed on the conductive fixed tool 13 form a pair of friction vice;

[0036] The weak current loop circuit system 2 includes a weak current power supply 21, two wires 22 respectively connected to the positive pole 211 and the negative pole 212 of the weak current power supply 21, and a corresponding number of power connectors 23;

[0037] One end of a lead 22 is connected with the positive pole 211 of the weak point power supply 21, and the other end of the lead 22 is connected with the electric head 23, and one end of the other lead 22 is connected with the n...

Embodiment 3

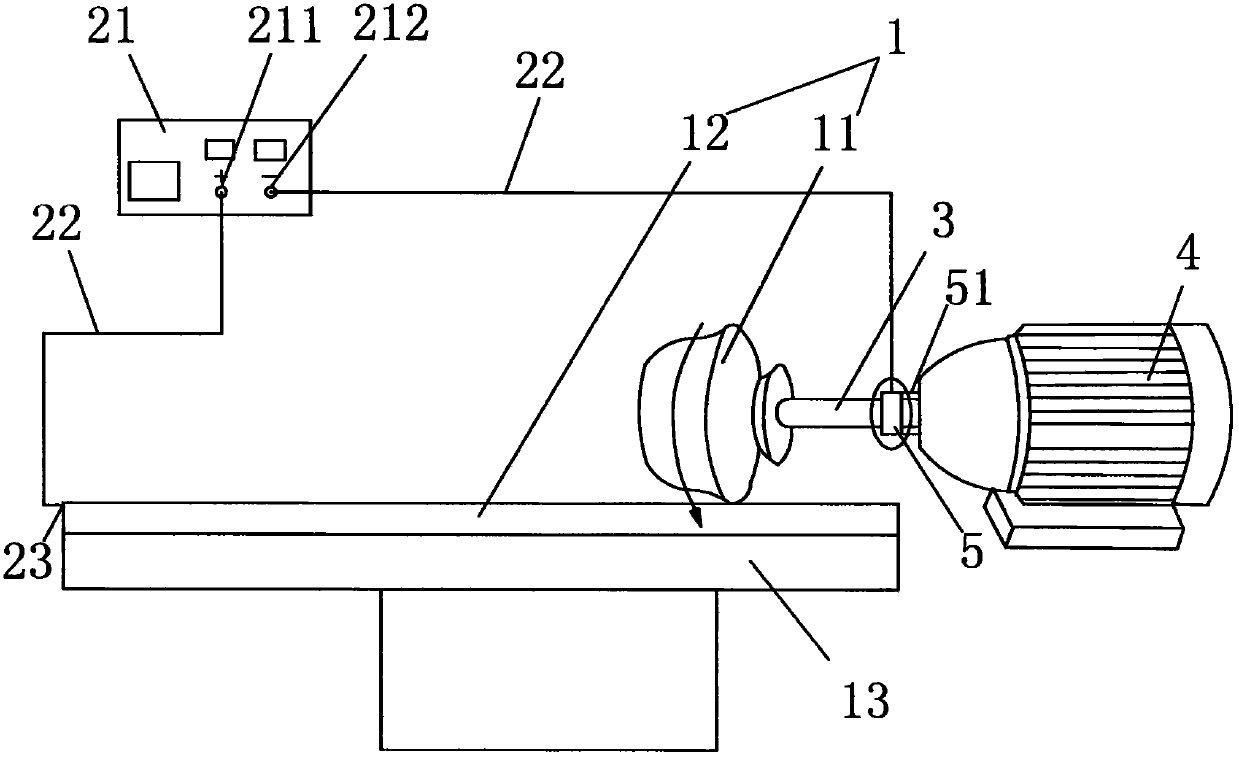

[0042] see image 3 and Figure 4 As shown, a dust-free polishing device for metal products includes a polishing system 1 and a set of weak current loop circuit systems 2;

[0043] The polishing system 1 includes a conductive polishing wheel 11, a metal product 12 to be processed, and a conductive fixed tool 13 for fixing the metal product 12 to be processed. The conductive polishing wheel 11 and the metal product 12 to be processed fixed on the conductive fixed tool 13 form a pair of friction vice;

[0044]The weak current loop circuit system 2 includes a weak current power supply 21, two wires 22 respectively connected to the positive pole 211 and the negative pole 212 of the weak current power supply 21, and a corresponding number of power connectors 23;

[0045] One end of a lead 22 is connected with the positive pole 211 of the weak point power supply 21, and the other end of the lead 22 is connected with the electric head 23, and one end of the other lead 22 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com