Derusting and dedusting collecting device for steel plate

A technology for collecting devices and steel plates, which is applied in the direction of grinding/polishing safety devices, grinding machines, and parts of grinding machine tools. Rust effect, simple structure, effect of improving rust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

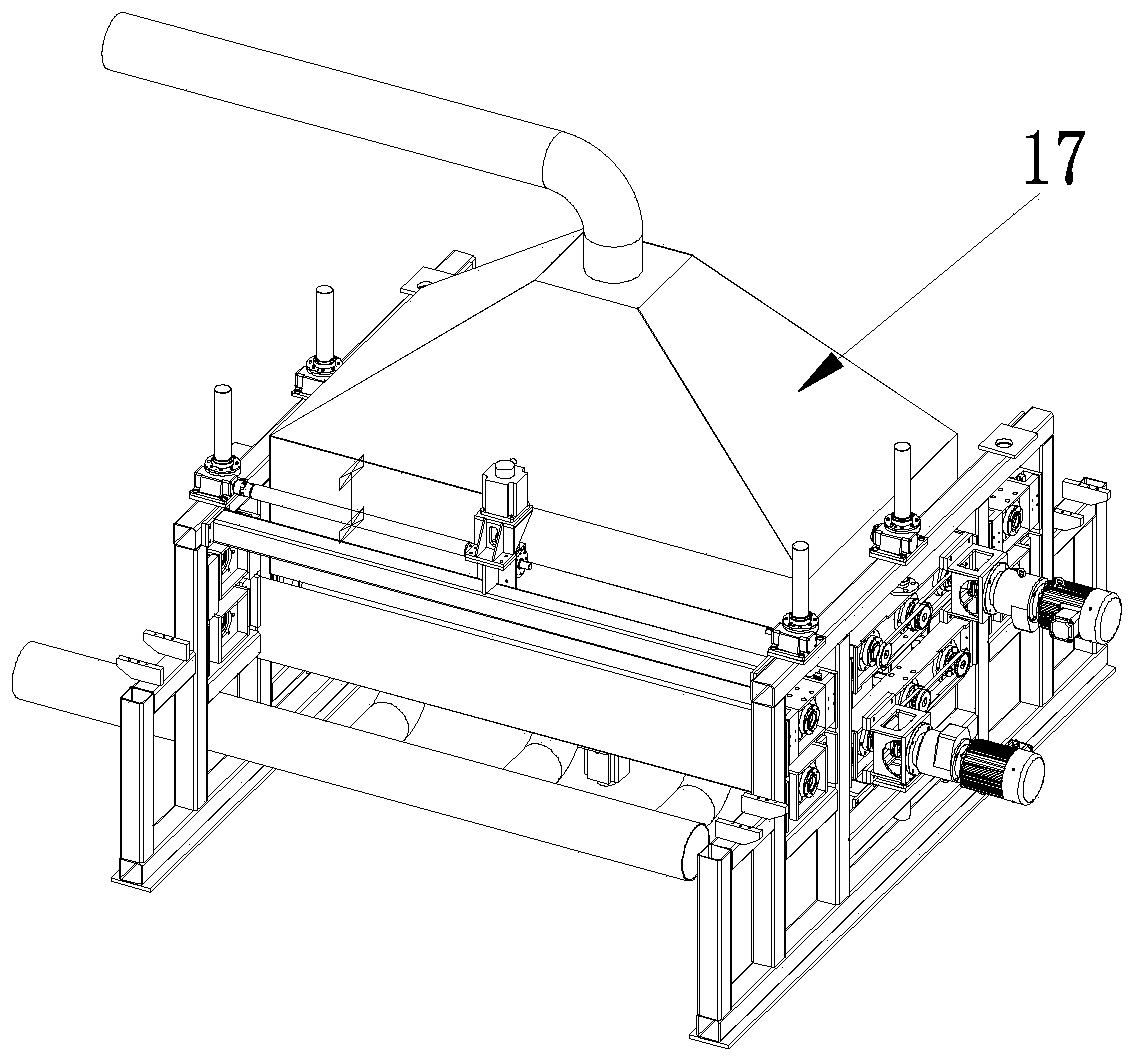

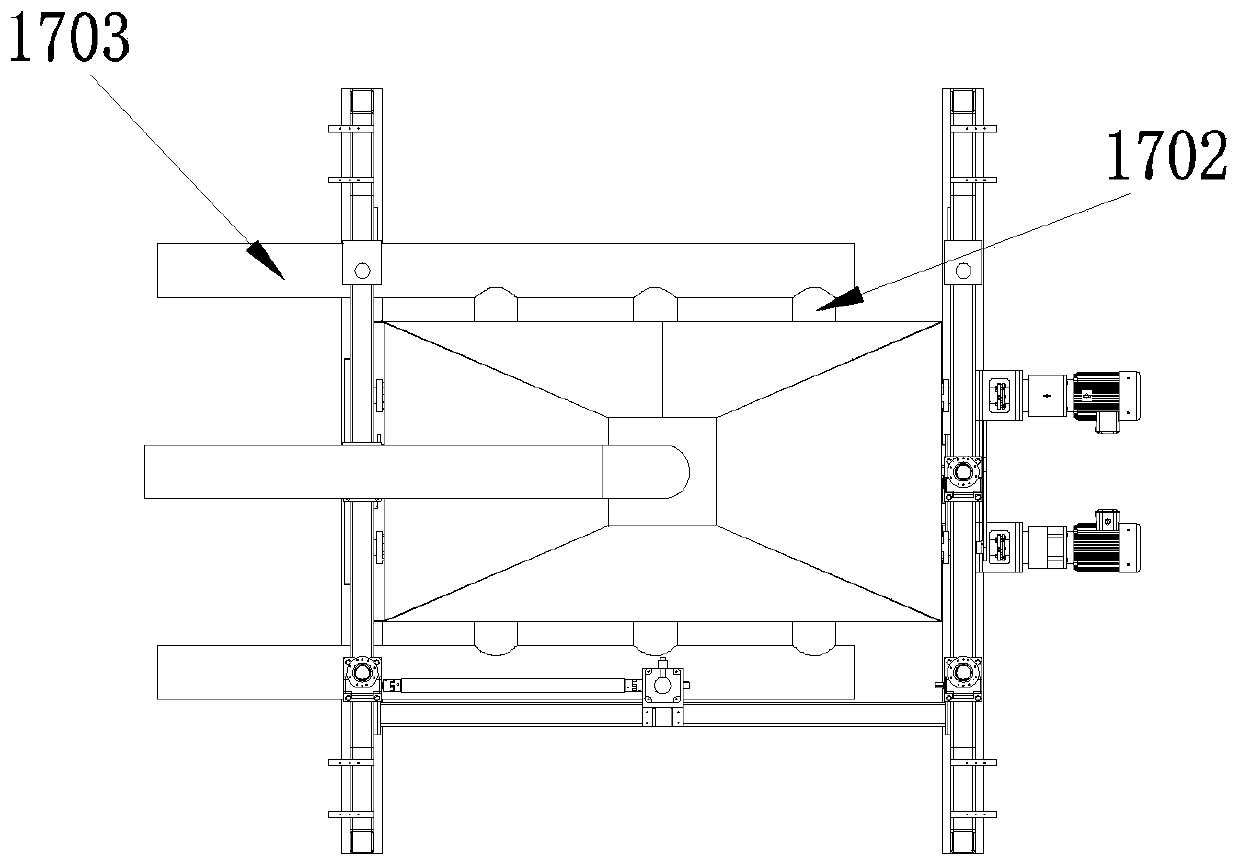

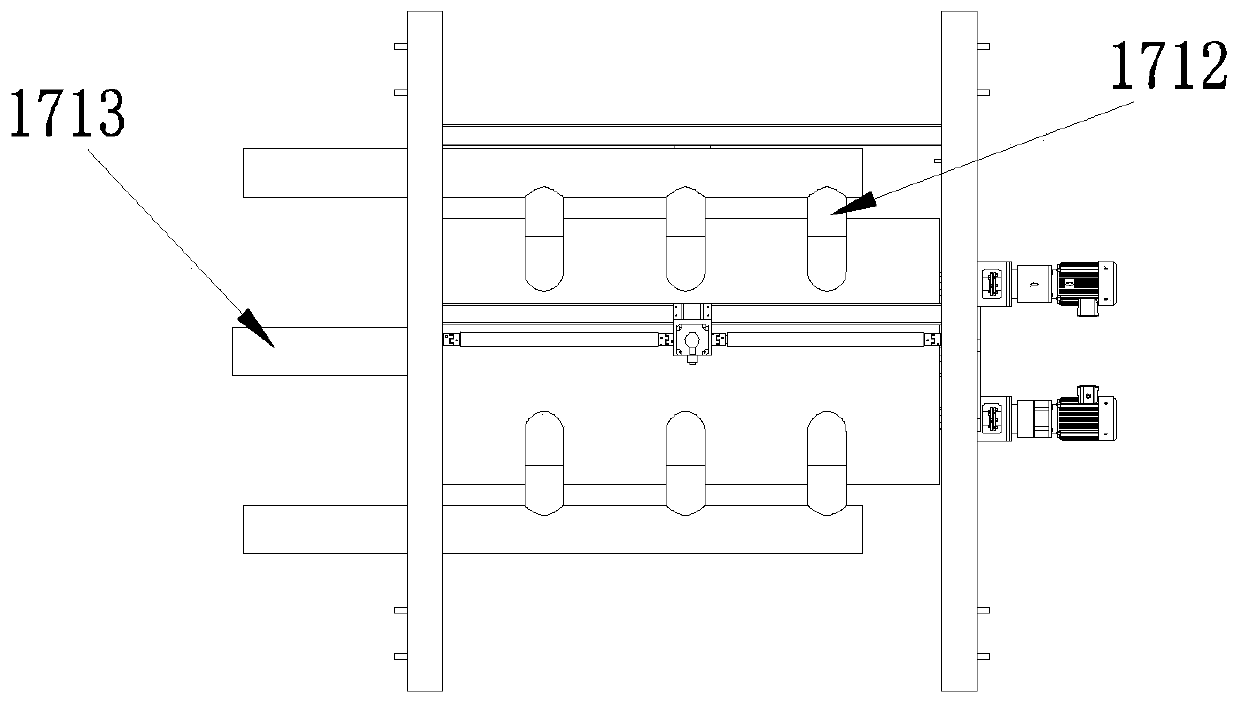

[0027] Embodiment 1: as Figure 1-4 As shown, a steel plate rust removal and dust collection device includes a closed dust collection cover 17 arranged on the upper end of the rust removal mechanism. The dust collection cover 17 is equipped with a fan, and the upper and lower ends of the rust removal mechanism are respectively equipped with an upper collection mechanism. 170 and the lower collection mechanism 171; the dust collection cover 17 is installed on the upper collection mechanism 170, and the upper collection mechanism 170 and the lower collection mechanism 171 are provided with through holes for steel plates to pass through; The surface of the rolling roller 44 on the mechanism is attached to the surface of the conveying roller 41, which is used to clean the upper and lower surfaces of the steel plate after deembroidering; the invention has a simple structure, is easy to use, and can quickly collect rust on the surface of the steel pipe Recycled, and can be completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com