Valve bonnet sealing gasket

A gasket and valve cover technology, which is applied to the sealing of the engine, the sealing device of the engine, the casing, etc., can solve the problems of long time and expensive process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

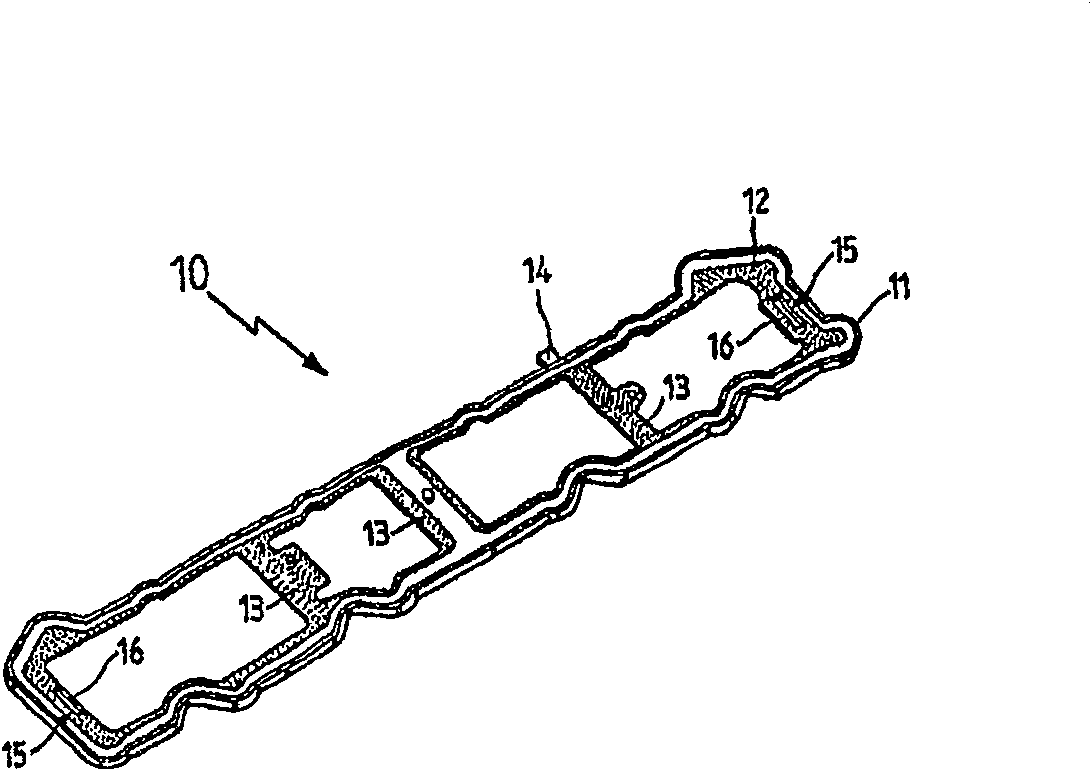

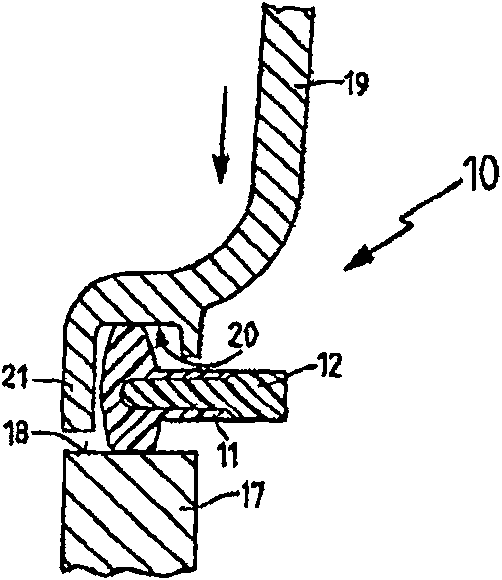

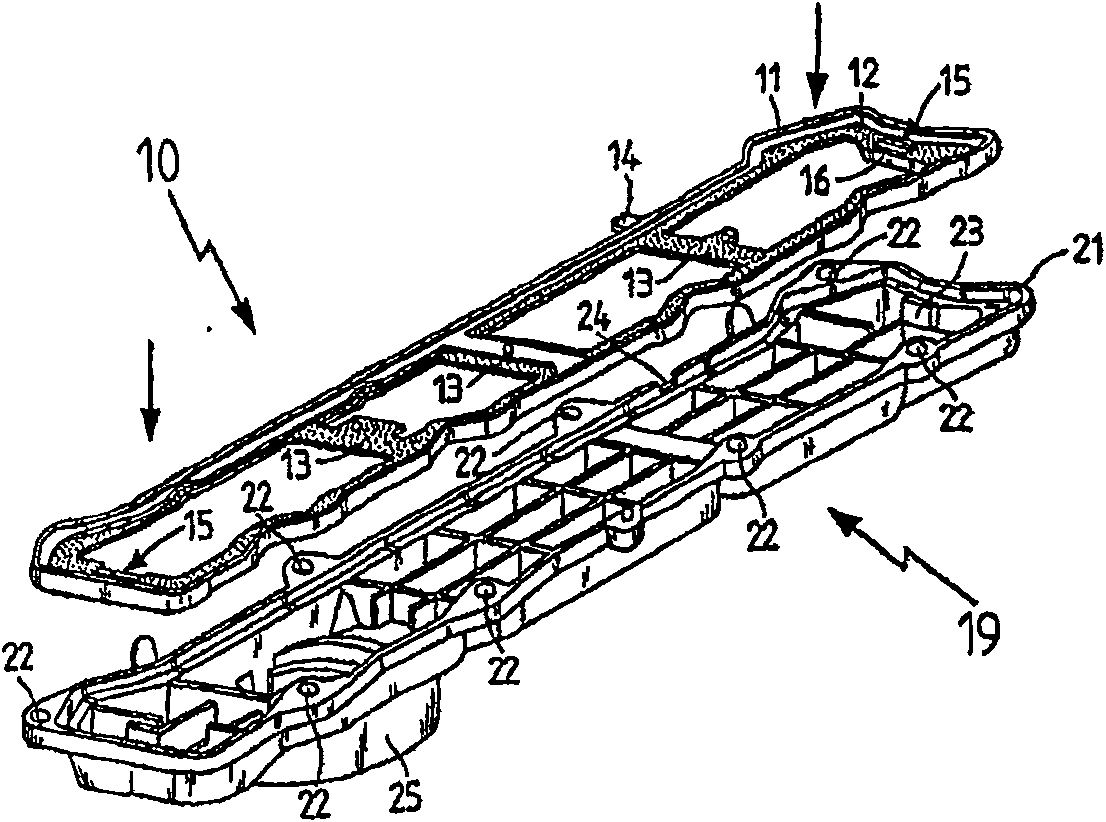

[0022] figure 1An embodiment of a gasket 10 according to the invention with an elastic bead 11 injection-molded on a support frame 12 is shown. The elastic sealing edge 11 has a defined outer contour which matches the contour of the corresponding molded part. In the inner area of the gasket 10 , the middle connecting piece 13 is arranged on the support frame 12 , and the middle connecting piece can enhance the stability of the whole gasket 10 . The height of the sealing edge 11 starting from the gasket plane clearly exceeds the thickness of the support frame 12, thereby ensuring that, when the two molded parts are assembled with the inserted gasket, the sealing edge will be at any point on its contour. can be compressed. An indicator 14 is arranged on the outer circumference of the sealing lip 11 . This indicator 14 is to be injected onto the support frame 12 together with the sealing bead 11 in an injection mold. It is not meant to interrupt the sealing edge, so the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com