Machine for laying infiltration irrigation pipeline

A technology of seepage irrigation pipe and pipe laying machine, which is applied in the field of agricultural machinery, can solve the problems that the greenhouse seepage irrigation pipe cannot be laid, the soil disturbance is large, and the structure is large, and the consistency of the opening depth is good, and the soil disturbance is small. , Good straight-line driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

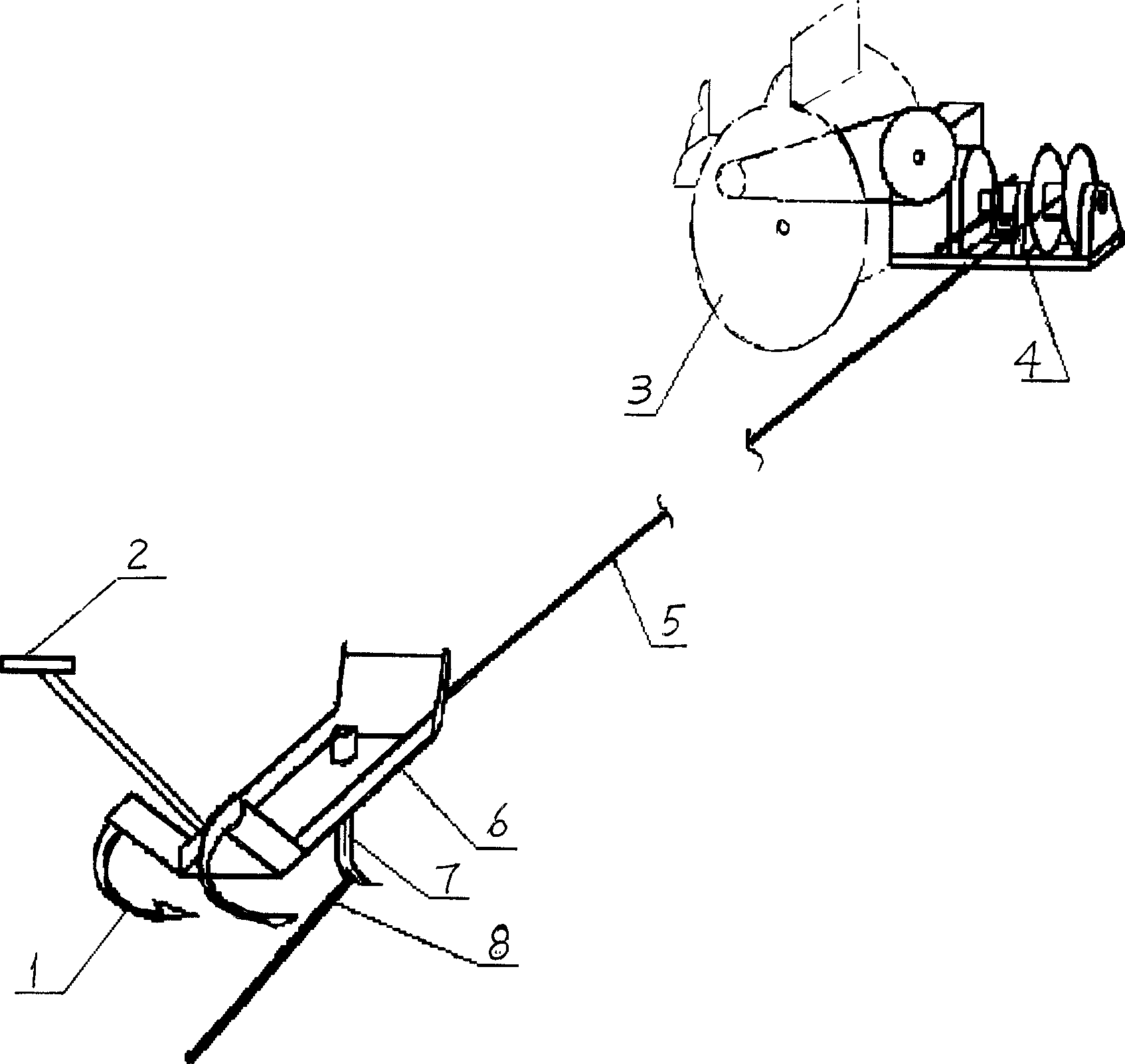

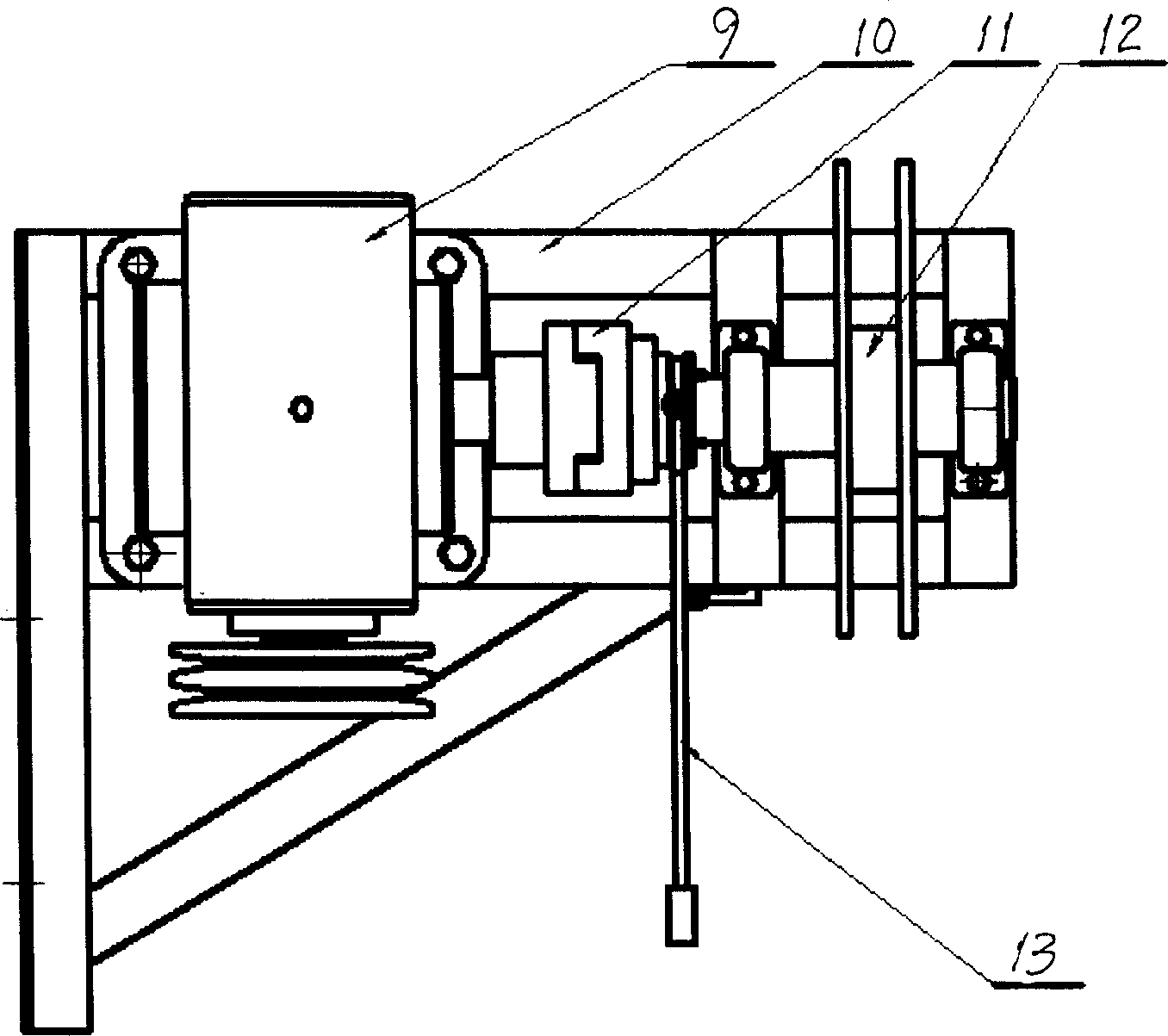

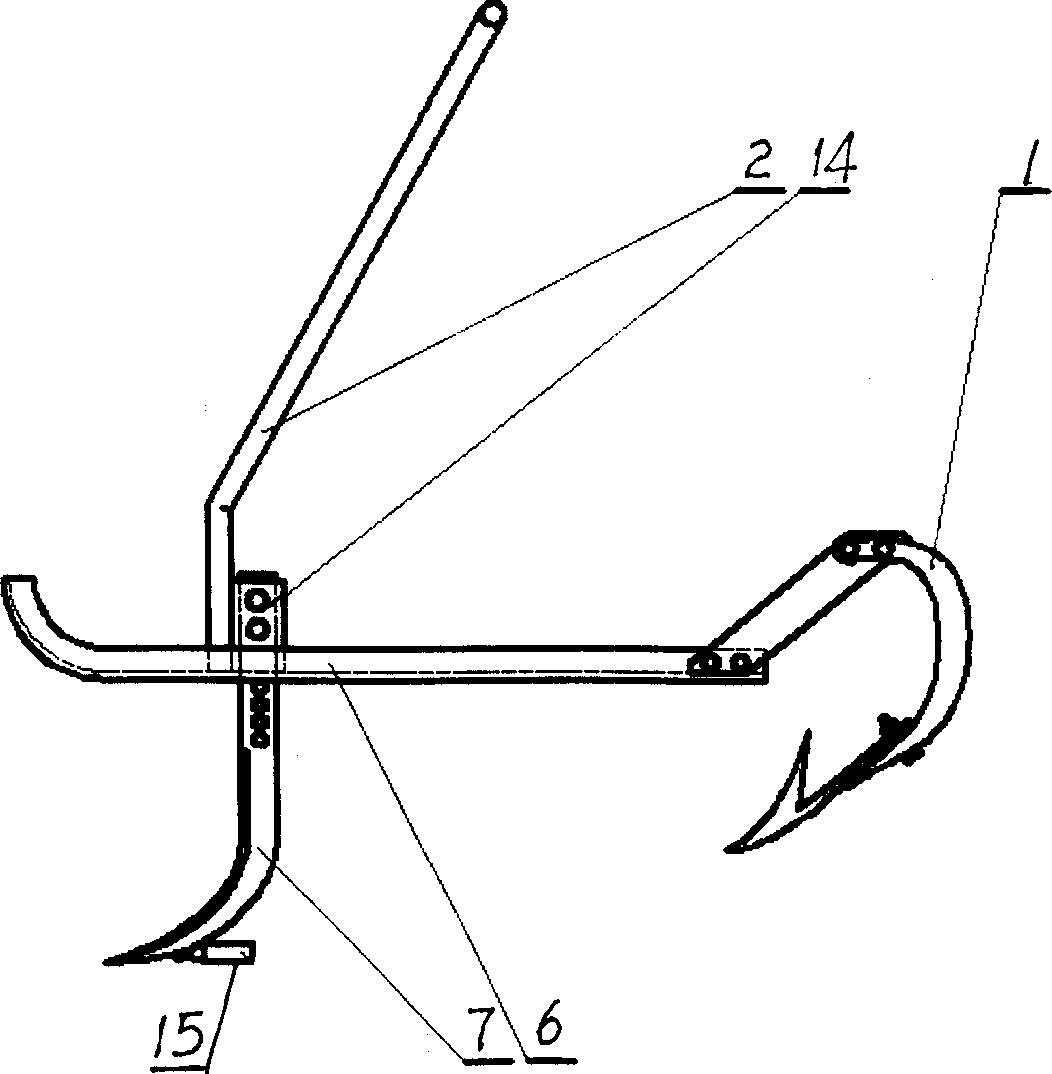

[0013] See Figure 1-5 , the concrete structure is as follows: the traction mechanism 4 is provided with a frame 10, and a wire rope winch 12 is assembled on the frame 10, and the wire rope winch 12 is connected to the worm gear reducer 9 through a clutch 11 transmission, and the output end of the worm reducer 9 is a transmission pulley, see figure 1 , the transmission pulley is connected with the external tractor 3 power output shaft through the transmission belt. The pipe laying mechanism is provided with a casing 6, the upper part of the casing 6 is connected to the handrail 2, and the opener 7 is installed on the lower part of the casing through the pipe laying depth adjustment hole 14 on it. The opener 7 is provided with a opener blade 16, and the opener 7. Hinge the connection sleeve 15 of the seepage irrigation pipe through the hinge shaft 17, the installation pin 18 connecting the seepage irrigation pipe is set on the connection sleeve 15 of the seepage irrigation pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com