Driving apparatus of bottom hook frame in net knitting machine

A driving device and net weaving machine technology, applied in the field of net weaving machines, can solve problems such as poor working stability, low mesh output, and high labor intensity, and achieve the effects of stable operation, reasonable and compact structure, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the above-mentioned accompanying drawings.

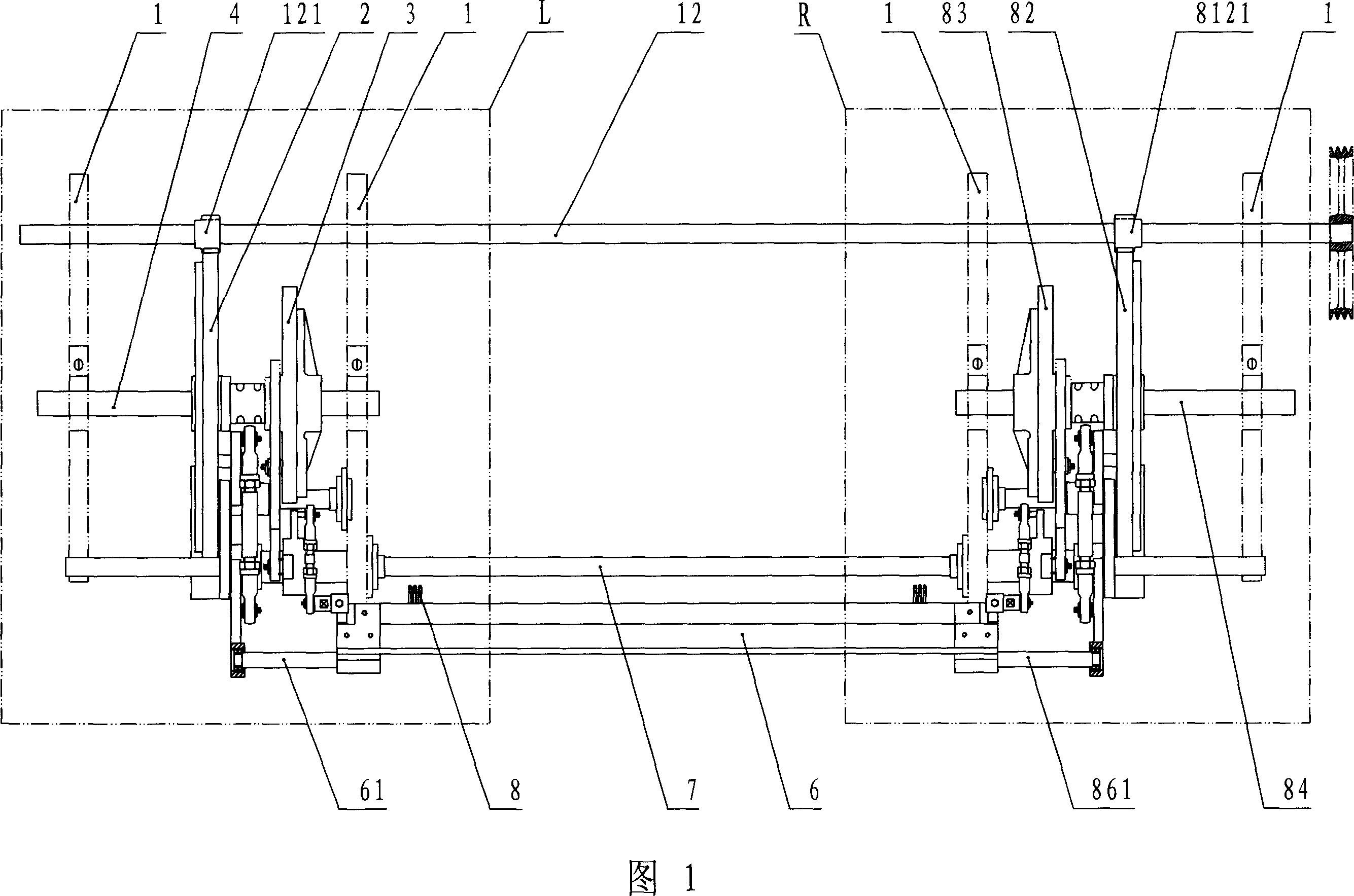

[0024] As shown in Figure 1, the driving device of the lower hook frame in the described netting machine includes: a frame 1 and a lower hook frame 6, the lower hook 8 is installed on the lower hook frame 6, and the frame 1 is provided with a main shaft 12 and The upper and lower shafts 7 on the orifice, and the left and right sides of the lower hook frame 6 are provided with a left drive structure L and a right drive structure R that are arranged axially symmetrically and cooperate with each other during work.

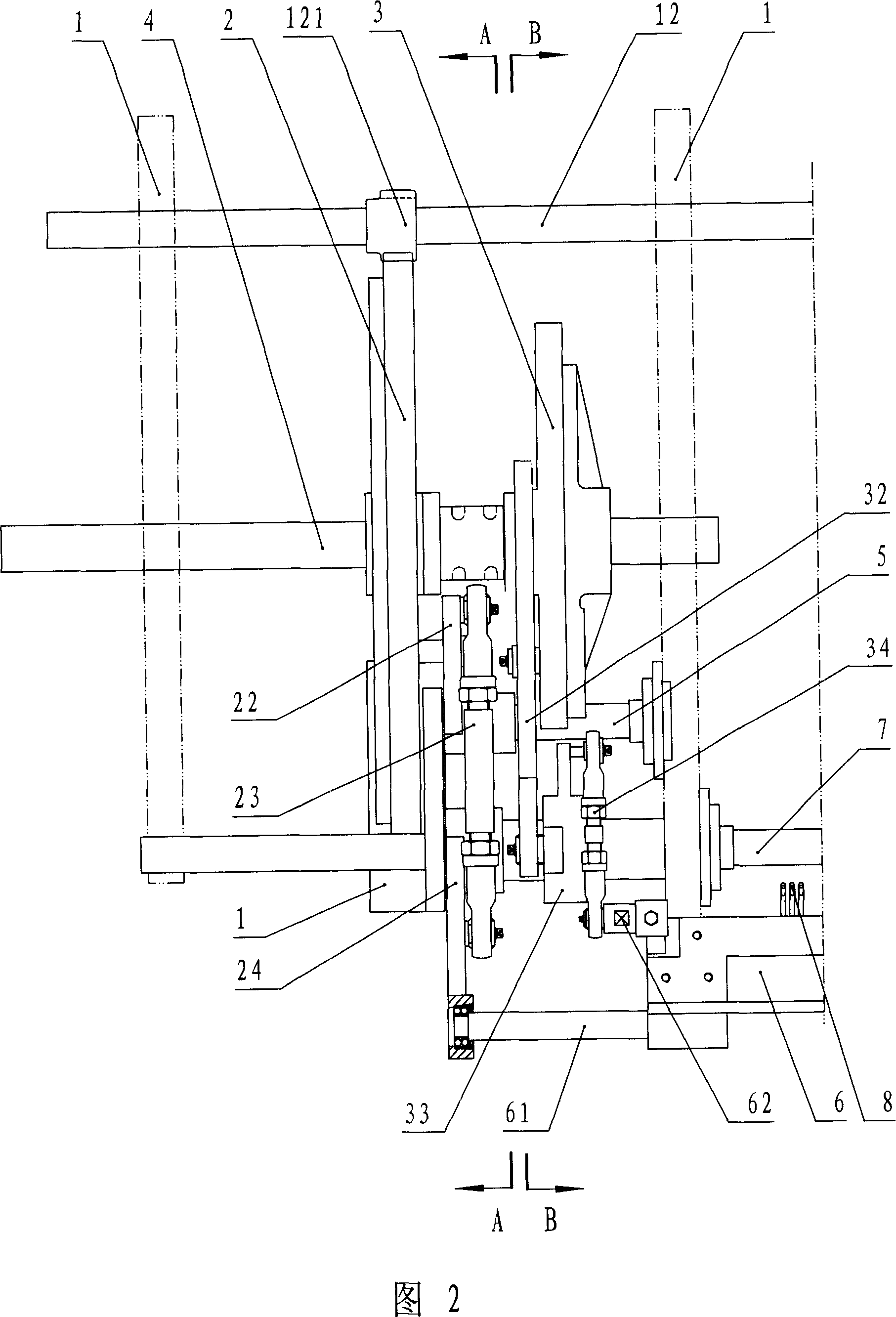

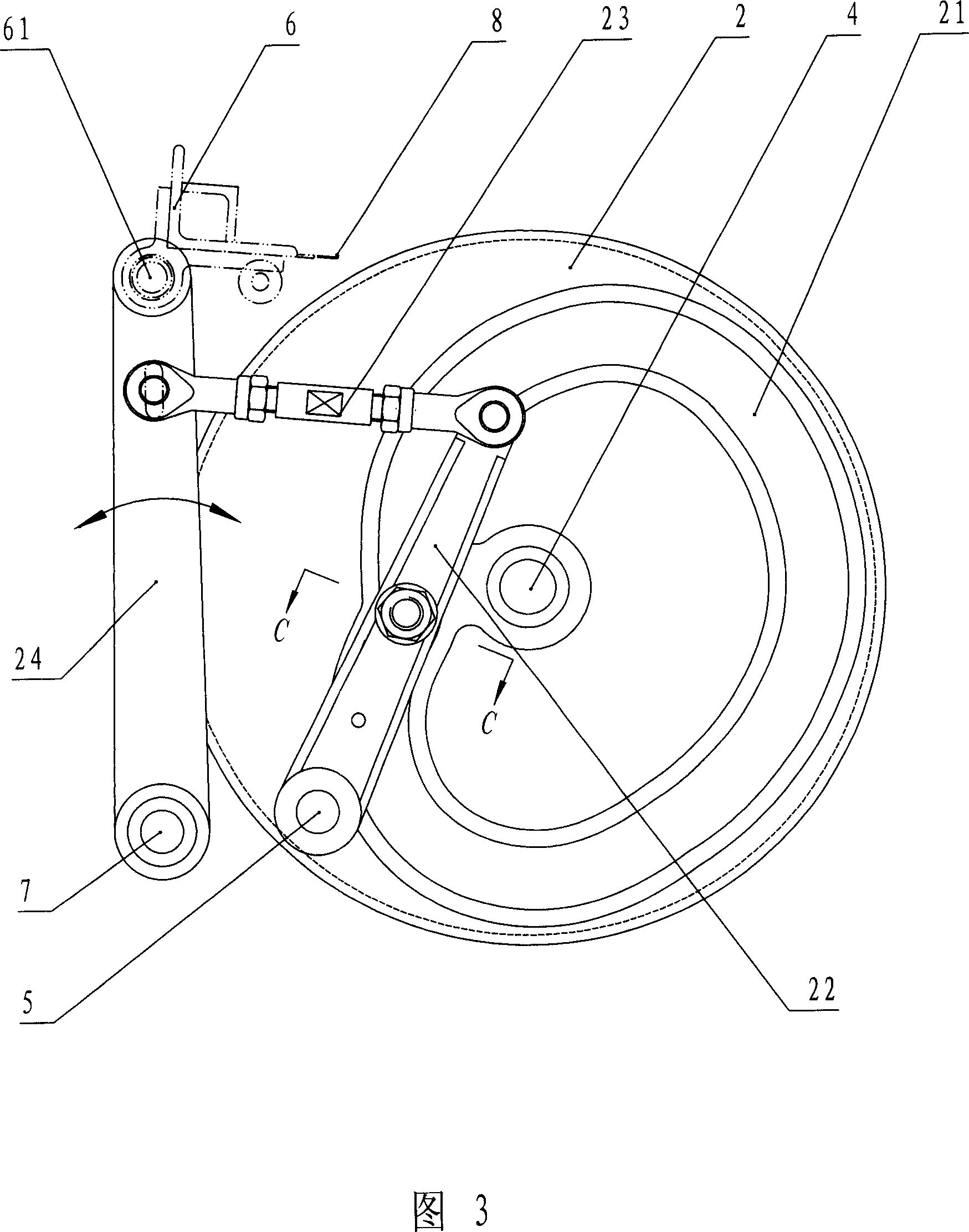

[0025] As shown in Figure 2, the structure of the left drive structure L includes: the left large gear 2 that can drive the lower hook frame 6 to move back and forth and the left upper and lower cam 3 that can drive the lower hook frame 6 to move up and down are fixedly installed on the On a left transmission shaft 4, the left transmission shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com