Hinge

A technology of hinges and hinge boxes, applied in the field of hinges, which can solve the problems of loud action noise, hinge box falling out, and easy wear and tear, and achieve the effects of reducing action sounds, impact sounds, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

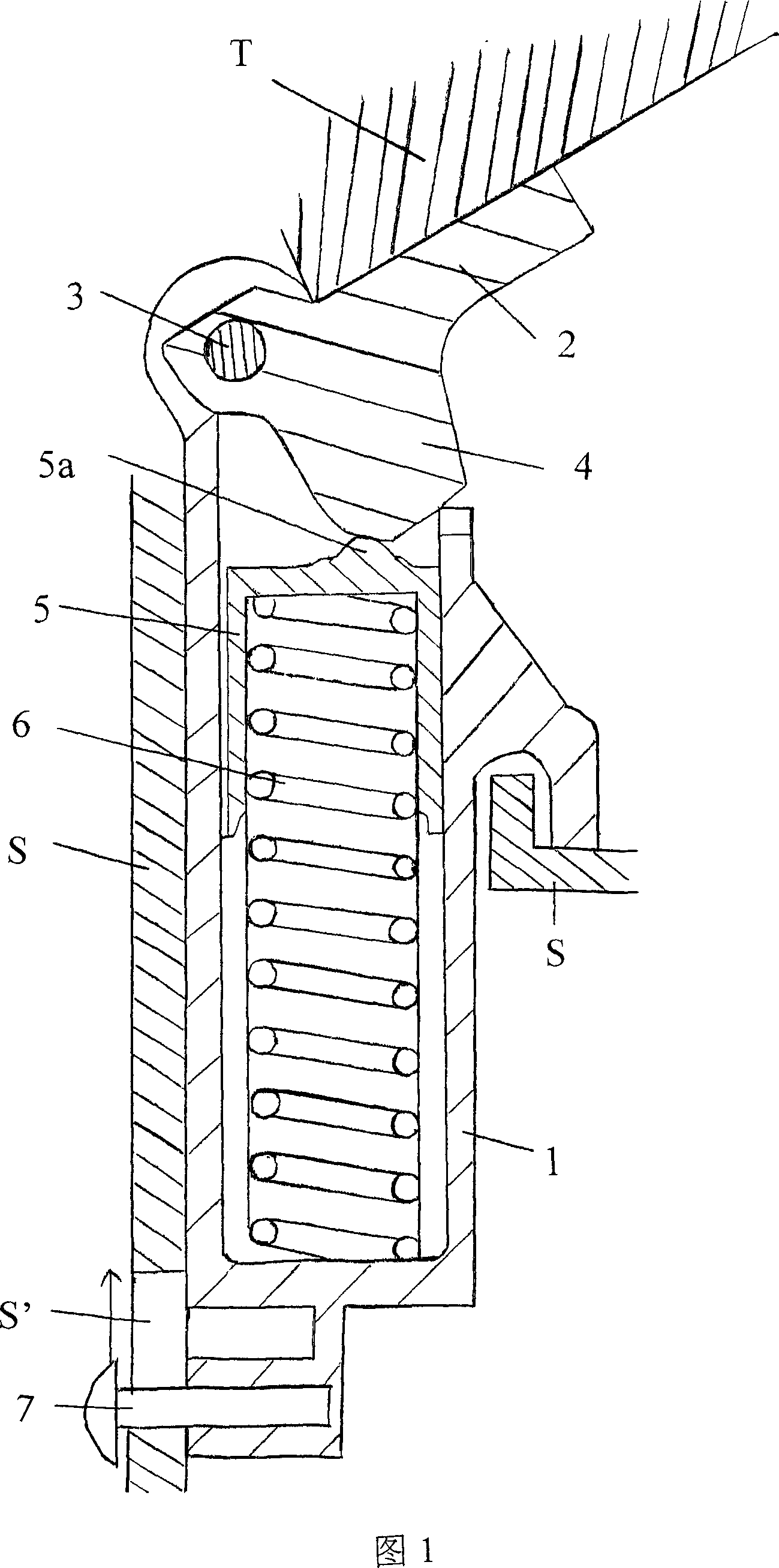

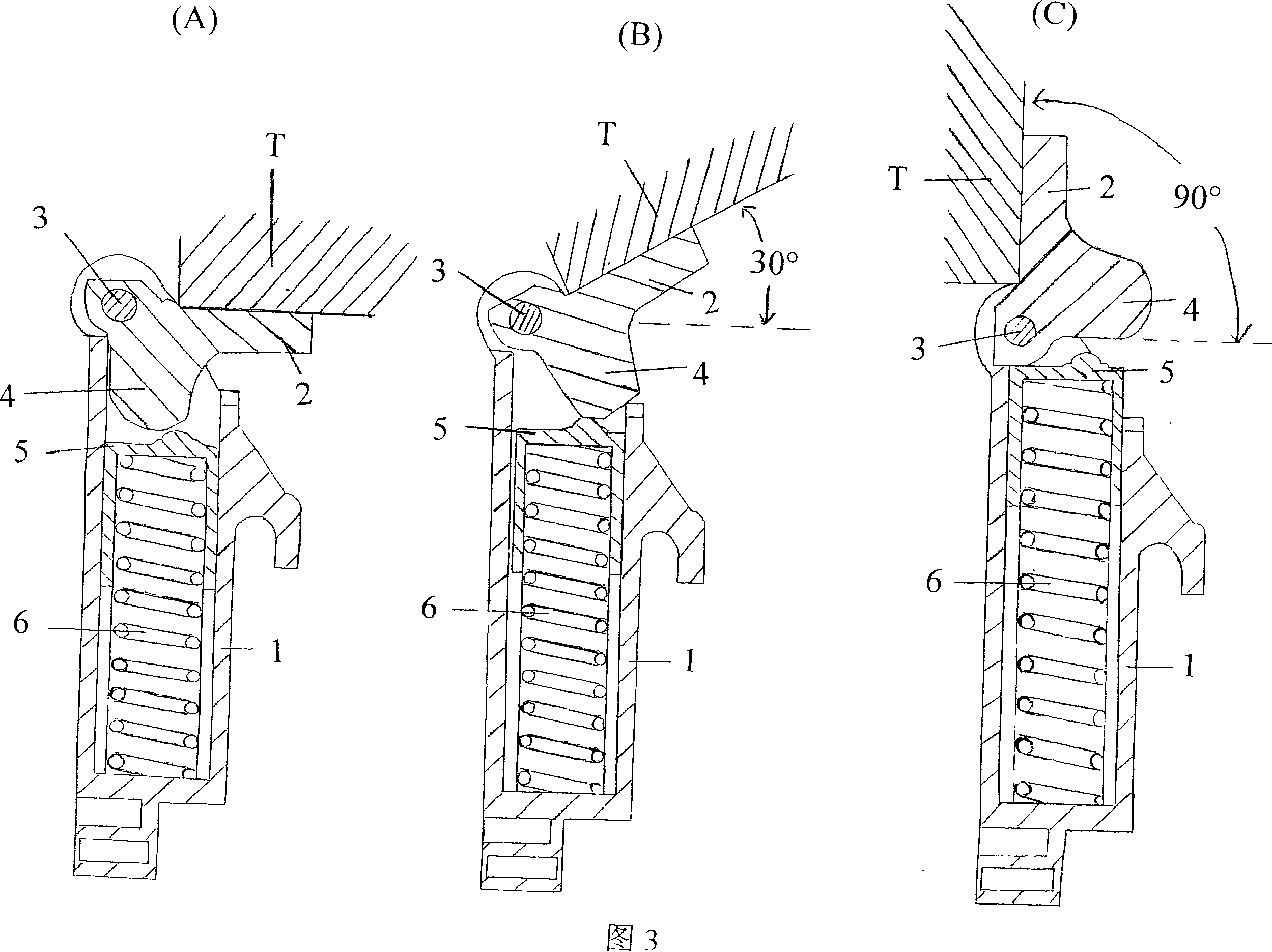

[0038] Fig. 1 is a drawing showing an embodiment of the hinge of the present invention. 1 is a hinge box, 2 is a rotating arm, 3 is a fulcrum, 4 is a cam, 5 is a slide block, and 6 is a spring.

[0039] The above-mentioned hinge box 1 is vertically slidably inserted into a fixed-side member S of a main body of an apparatus such as a copier. The anti-dropping pin 7 is installed and fixed on the lower end of the hinge box 1 by means of screwing in or pressing in. The anti-dropping pin 7 extends into the long hole S' provided on the fixed side member S. Therefore, the above-mentioned hinge box 1 can only move up and down within a prescribed stroke.

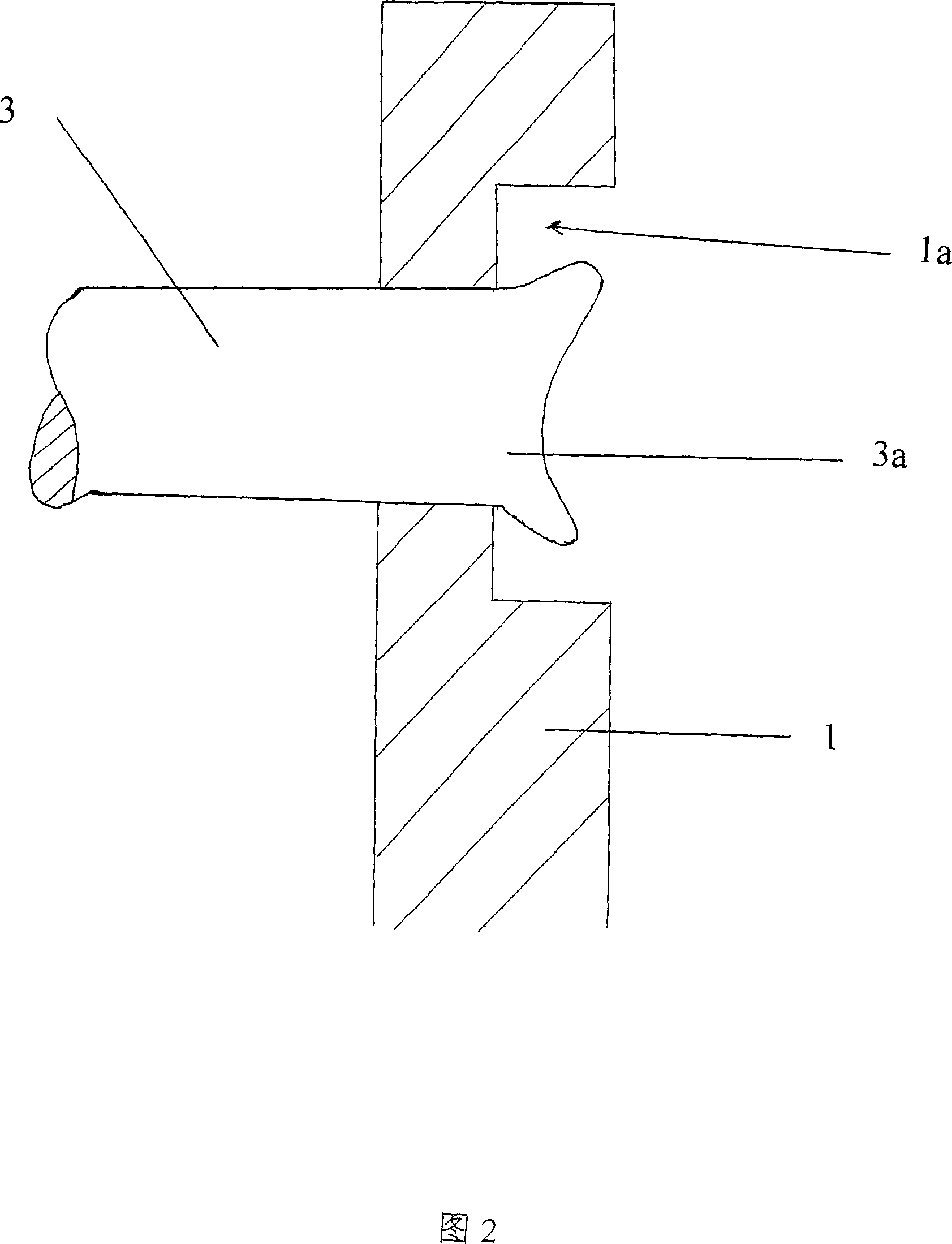

[0040] The above-mentioned rotating arm 2 is pivotally connected to the upper end of the above-mentioned hinge box 1 through the support shaft 3 in a freely rotatable manner. As shown in FIG. 2, if the support shaft 3 is made of metal, at least one end thereof is riveted 3a to prevent it from coming off. In order not to expose th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com