Packaging method of cylindrical lithium ion battery

A lithium-ion battery and packaging method technology, which is applied to secondary batteries, battery pack parts, non-aqueous electrolyte storage batteries, etc., can solve the problems of high raw material cost, complicated processing process, and high manufacturing cost, and achieve low raw material cost and low processing cost. Simple process and high energy-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

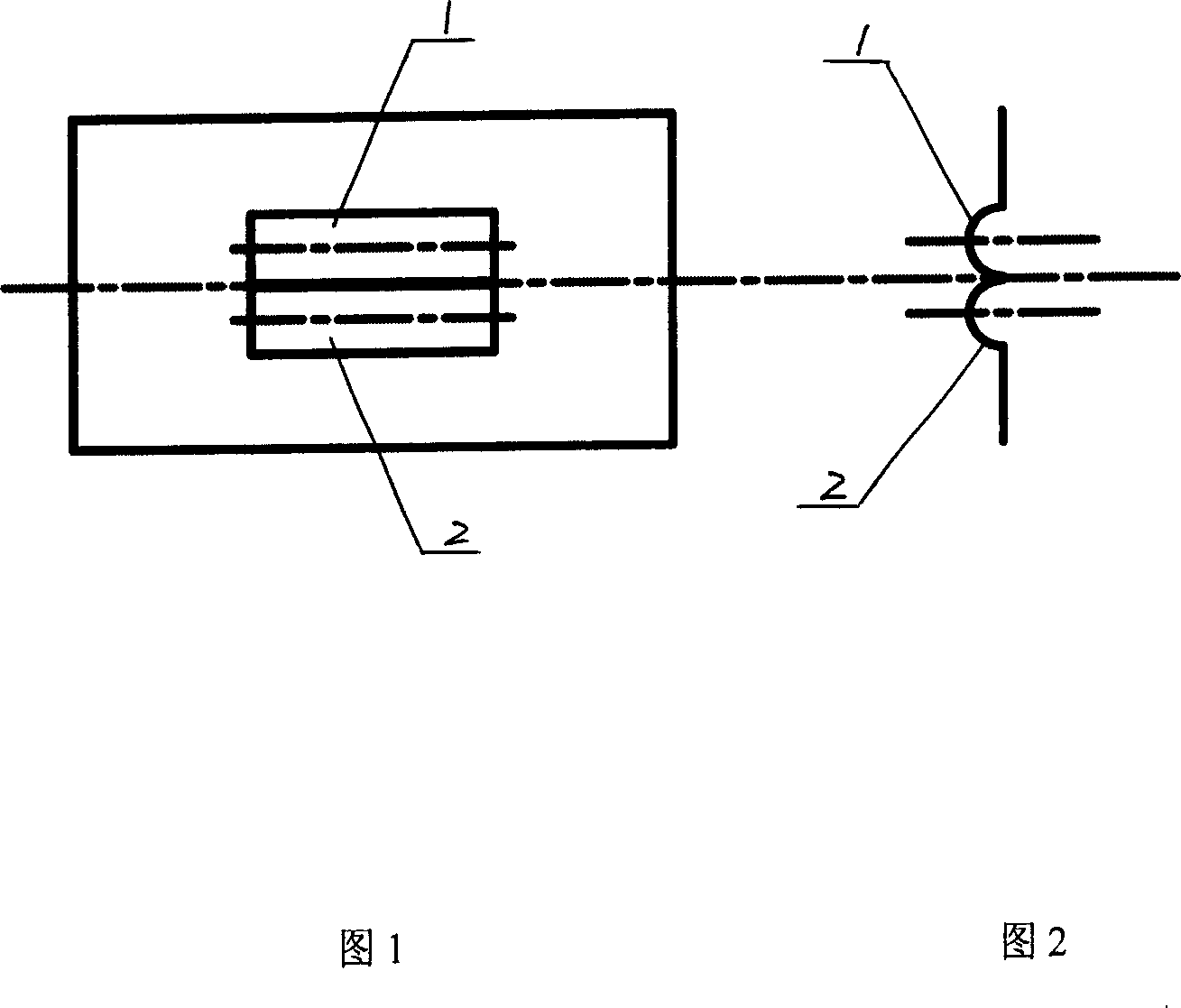

[0009] First, use the aluminum-plastic packaging bag as the battery casing material, as shown in Figure 1, punch out two equal semi-cylindrical shapes 1 and 2 in the middle of one side of the aluminum-plastic packaging bag with a punching die, and then punch out the two semi-cylindrical shapes 1 and 2. After the cylindrical shape is folded in half, it becomes a cylindrical shape (as shown in Figure 2, the semi-cylindrical shapes 1 and 2 are folded in half), and finally the battery poles are assembled into the above-mentioned stamped aluminum-plastic bag shell, which is double-sealed, liquid injected, and drained. Gas, unilateral sealing, and formation processes complete battery packaging.

[0010] The invention adopts an aluminum-plastic packaging bag as the casing of the cylindrical lithium-ion battery, and during the manufacturing process, processes such as rolling g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com