Driving plan of parallel multi-section contactless switch speed regulating machine

A non-contact switch and speed-regulating motor technology, applied in the electromechanical field, can solve the problems of low reliability of contact relays, affect system reliability, increase heat generation, etc., and achieve the effects of high cost performance, high reliability and high power factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

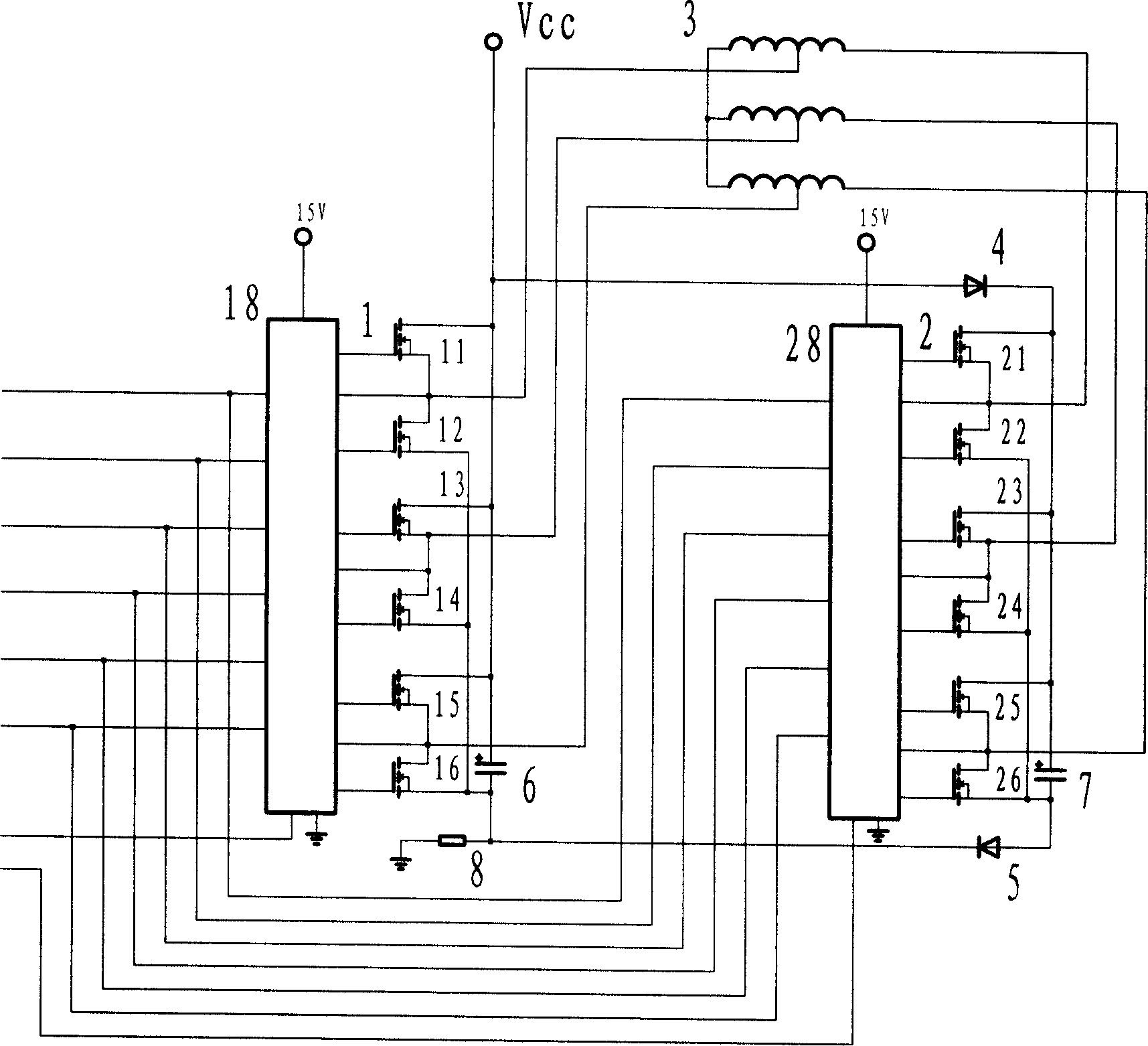

[0014] The technical scheme of the parallel multi-stage non-contact switch speed-regulating motor drive system is described in detail below through illustrations. This embodiment takes a dual-speed (also known as dual-power) three-phase brushless DC motor parallel connection high and low two-stage non-contact power drive scheme as an example.

[0015] With reference to the accompanying drawings: the motor winding 3 is a type with taps for each phase, and high and low speeds respectively have a set of drive circuits 1 and 2, which are composed of 11-16 and 22-26 respectively. When the motor system starts at low speed, the control circuit selects the pre-drive chip 28 through the chip select port, the low-speed drive circuit 2 is powered, and all windings of the drive motor work. After the motor speed is increased to a certain value, the control circuit makes the chip 28 quit working by the chip selection circuit, and simultaneously selects the high-speed pre-drive circuit 18 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com