Effective components of rose, its preparing method and use

A technology of effective parts and roses, applied in the fields of medicine and health, food and chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

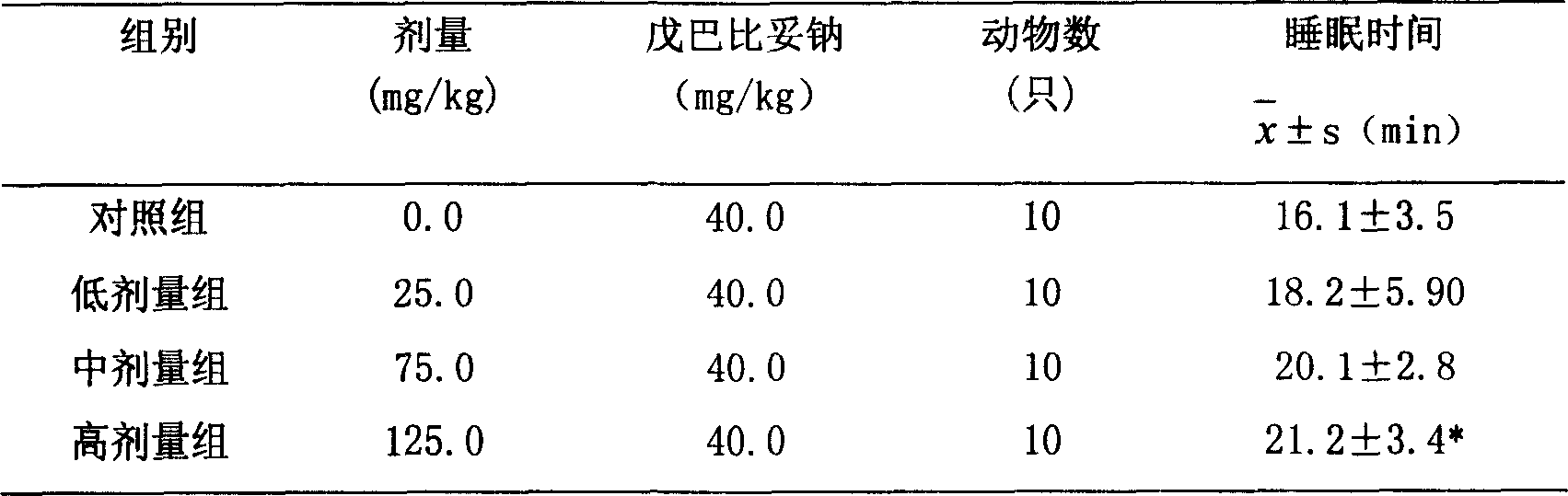

Image

Examples

Embodiment 1

[0034] a. Dried roses 100g, add 1L 80% ethanol, heat in a water bath at 90°C, reflux extraction twice, each time for 2 hours, filter, the filtrate is concentrated under reduced pressure until it has no alcohol smell, let it stand for 24 hours, and pour out the supernatant;

[0035] b. Take the supernatant and load it on the D140 type macroporous adsorption resin chromatography column, and then wash it with water, 25% ethanol, 50% ethanol, and 95% ethanol in sequence;

[0036] c. Concentrate the part obtained by elution with water and then extract it with n-butanol, separate the n-butanol layer, concentrate under reduced pressure, and dry in vacuum to obtain component Fr1 for later use;

[0037] d. Recover ethanol from the part obtained by eluting with 25% ethanol in step b, then extract with n-butanol, separate the n-butanol layer, concentrate under reduced pressure, and dry in vacuo to obtain component Fr2 for later use;

[0038]e. Concentrate and dry under reduced pressure t...

Embodiment 2

[0042] a. Add 1L of 70% ethanol to 100g of dried roses, heat in a water bath at 100°C, reflux and extract twice, each time for 2 hours, filter, concentrate the filtrate under reduced pressure until it has no alcohol smell, let it stand for 24 hours, and pour out the supernatant;

[0043] b. Take the supernatant and load it on the X-5 type macroporous adsorption resin chromatography column, and then wash it with water, 25% ethanol, 50% ethanol, and 95% ethanol in sequence;

[0044] c. Concentrate the parts obtained by elution with water, then extract with n-butanol, separate the n-butanol layer, concentrate under reduced pressure, and dry in vacuo to obtain component Fr1 for later use;

[0045] d. Recover ethanol from the part obtained by eluting with 25% ethanol in step b, then extract with n-butanol, separate the n-butanol layer, concentrate under reduced pressure, and dry in vacuo to obtain component Fr2 for later use;

[0046] e. Concentrate and dry under reduced pressure t...

Embodiment 3

[0050] a. Add 100g of dried roses, add 1L of 90% ethanol, heat in a water bath at 80°C, reflux and extract twice, each time for 2 hours, filter, concentrate the filtrate under reduced pressure until it has no alcohol smell, let it stand for 24 hours, and pour out the supernatant;

[0051] b. Take the above-mentioned supernatant and load it on the AB-8 type macroporous adsorption resin chromatography column, and then wash it with water, 25% ethanol, 50% ethanol, and 95% ethanol in sequence;

[0052] c. Concentrate the parts obtained by elution with water, then extract with n-butanol, separate the n-butanol layer, concentrate under reduced pressure, and dry in vacuo to obtain component Fr1 for later use;

[0053] d. After ethanol is recovered from the part obtained by eluting with 25% ethanol in step b, it is then extracted with n-butanol, and the n-butanol layer is separated, concentrated under reduced pressure, and dried in vacuum to obtain component Fr2 for later use;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com