Broken stone type haydites of book structure in use for lightweight concrete, and manufacturing process

A technology of lightweight concrete and shale ceramsite, applied in the field of concrete building materials, can solve problems such as unsatisfactory development, and achieve the effect of saving power energy and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

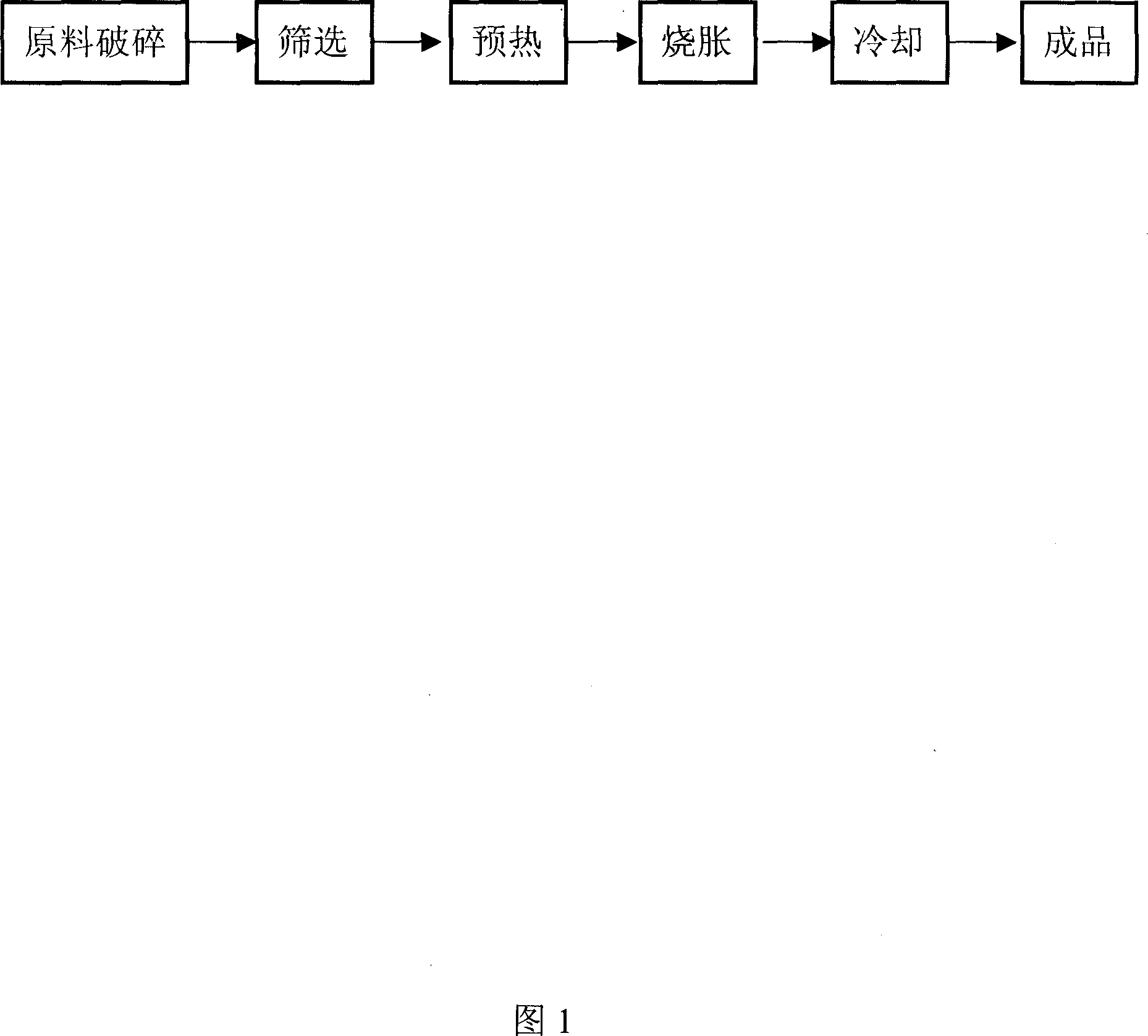

Method used

Image

Examples

Embodiment 1

[0035] Table 1 shows the chemical composition analysis results of the clay shale used to produce high-strength or ultra-light ceramsite according to the present invention.

[0036] Element

[0037] The clayey shale described in Embodiment 1 has many kinds in the concept of geology, and the clayey shale used in the present invention is defined from the perspective of the characteristics used for the production of expanded ceramsite. Shale can be divided into two categories: swellable shale and non-swellable shale under the technical conditions of calcination of expanded shale ceramsite. The shale used in the present invention belongs to swellable clayey shale.

Embodiment 2-10

[0039] The process conditions and products of the present invention producing ultra-light type ceramsite, test results are as shown in table 2.

[0040] example

Embodiment 11-12

[0042] The process conditions and product inspection results of the present invention producing high-strength ceramsite are as shown in Table 3.

[0043] example

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com