Sapo-34 molecular sieve raw powder and its synthesis method

A technology of SAPO-34 and synthesis method, applied in the field of molecular sieves, to achieve the effect of friendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

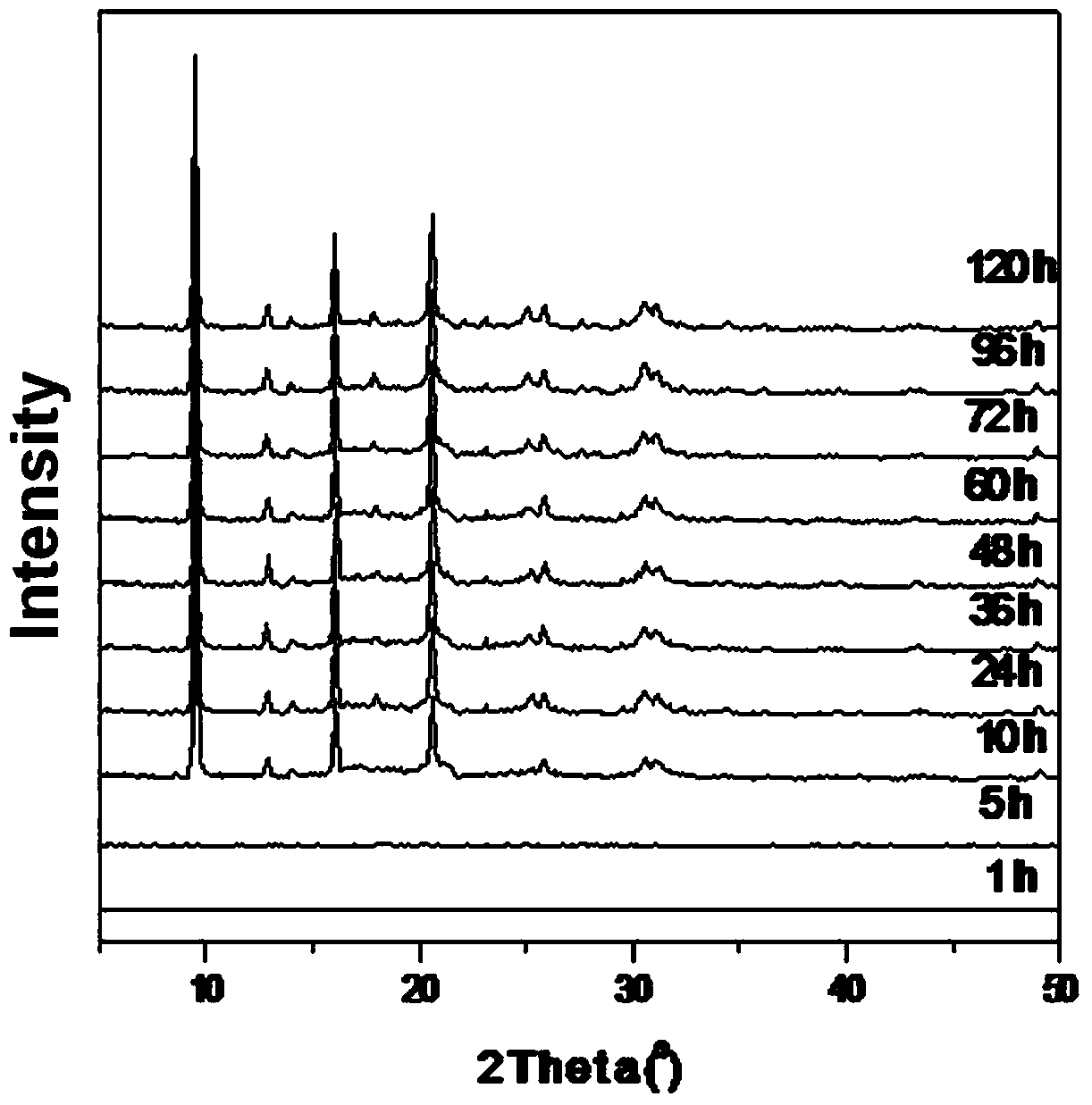

[0036] The above SAPO-34 molecular sieve raw powder provided by the present invention can be prepared by using a conventional SAPO-34 molecular sieve raw powder preparation process after mixing unqualified SAPO-34 molecular sieve raw powder into the synthetic raw material of SAPO-34 molecular sieve raw powder. In a preferred embodiment of the present invention, the method for synthesizing raw SAPO-34 molecular sieve powder includes the following steps: mixing the unqualified raw powder of SAPO-34 molecular sieve into the synthetic raw material of raw SAPO-34 molecular sieve powder to obtain the mixed raw material; and The mixed raw materials are subjected to aging, hydrothermal crystallization, and solid-liquid separation to obtain a solid phase in sequence, and the raw SAPO-34 molecular sieve powder is obtained after drying.

[0037] Applying the above-mentioned scheme provided by the invention, by using the unqualified raw powder of SAPO-34 molecular sieve produced due to the...

Embodiment 1

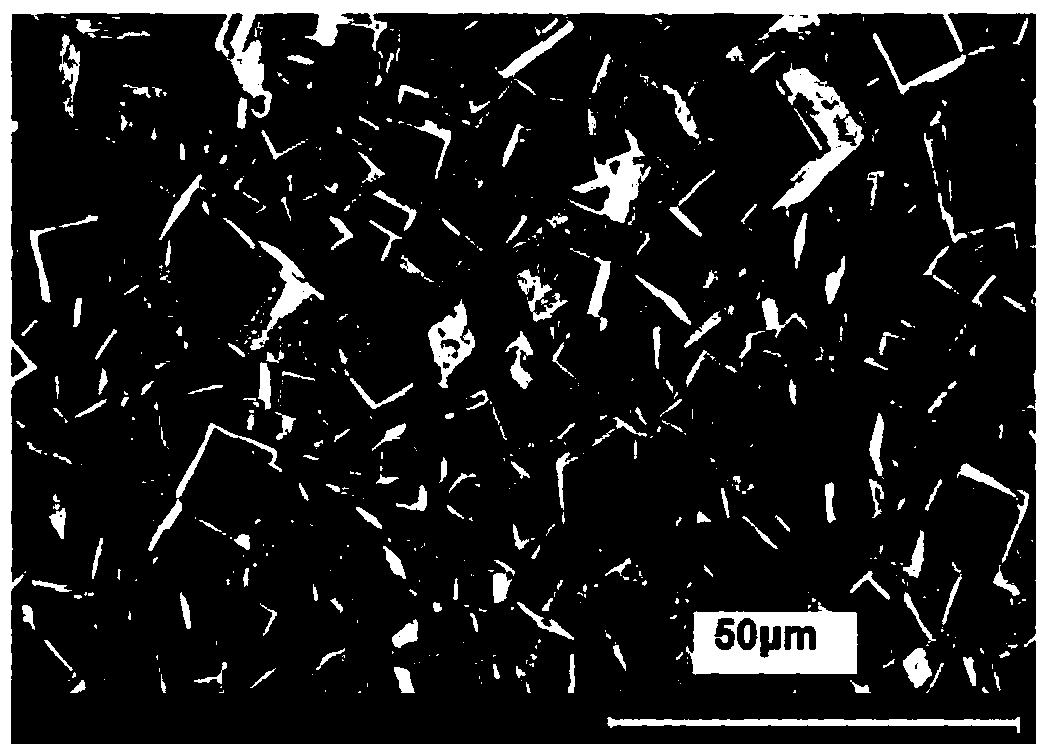

[0055] Using pseudo-boehmite, 85% phosphoric acid, and silica sol as raw materials, and triethylamine as a template, according to the molar ratio of raw materials Al 2 o 3 :P 2 o 5 :0.4SiO2 2 :3.0Et 3 N:50H 2 O configuration basic raw material powder, and according to the basic raw material powder of 90% in weight percentage, SAPO-34 molecular sieve unqualified former powder in 10% sample 1 (SEM figure is as shown figure 2 shown) were mixed to prepare the colloidal solution of SAPO-34 molecular sieve raw powder before crystallization. After aging at 40°C for 12h, they were crystallized at 200°C for 48 hours in a 150mL high-pressure hydrothermal kettle. Cut off the power supply of the hydrothermal crystallization kettle, after reducing the pressure and cooling down, unload the slurry into the discharge tank, after static stratification, put the lower layer slurry into the ground tank, and vacuum suction to the plate and frame filter device, the molecular sieve slurry Per...

Embodiment 2

[0057] Using pseudo-boehmite, 85% phosphoric acid, and silica sol as raw materials, and triethylamine as a template, according to the molar ratio of raw materials Al 2 o 3 :P 2 o 5 :0.4SiO2 2 :3.0Et 3 N:50H 2 O configure basic raw material powder, and according to the basic raw material powder of 95% in weight percentage, SAPO-34 molecular sieve unqualified former powder in 5% sample 2 is mixed to prepare SAPO-34 molecular sieve former powder crystallization front colloid solution, 50 ℃ After aging for 8 h, 36 were crystallized at 200 °C in a 150 mL autoclave. Cut off the power supply of the hydrothermal crystallization kettle, after reducing the pressure and cooling down, unload the slurry into the discharge tank, after static stratification, put the lower layer slurry into the ground tank, and vacuum suction to the plate and frame filter device, the molecular sieve slurry Perform solid-liquid separation. After repeated beating-filtration (pH=7), the separated solid ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com