Method and system for measuring trap parameter of insulating material of polymer

A technology of insulating materials and trap parameters, applied in the direction of measuring electricity, measuring devices, analyzing materials, etc., can solve the problems of lack of characterization methods, and achieve the effect of strong anti-electromagnetic interference and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

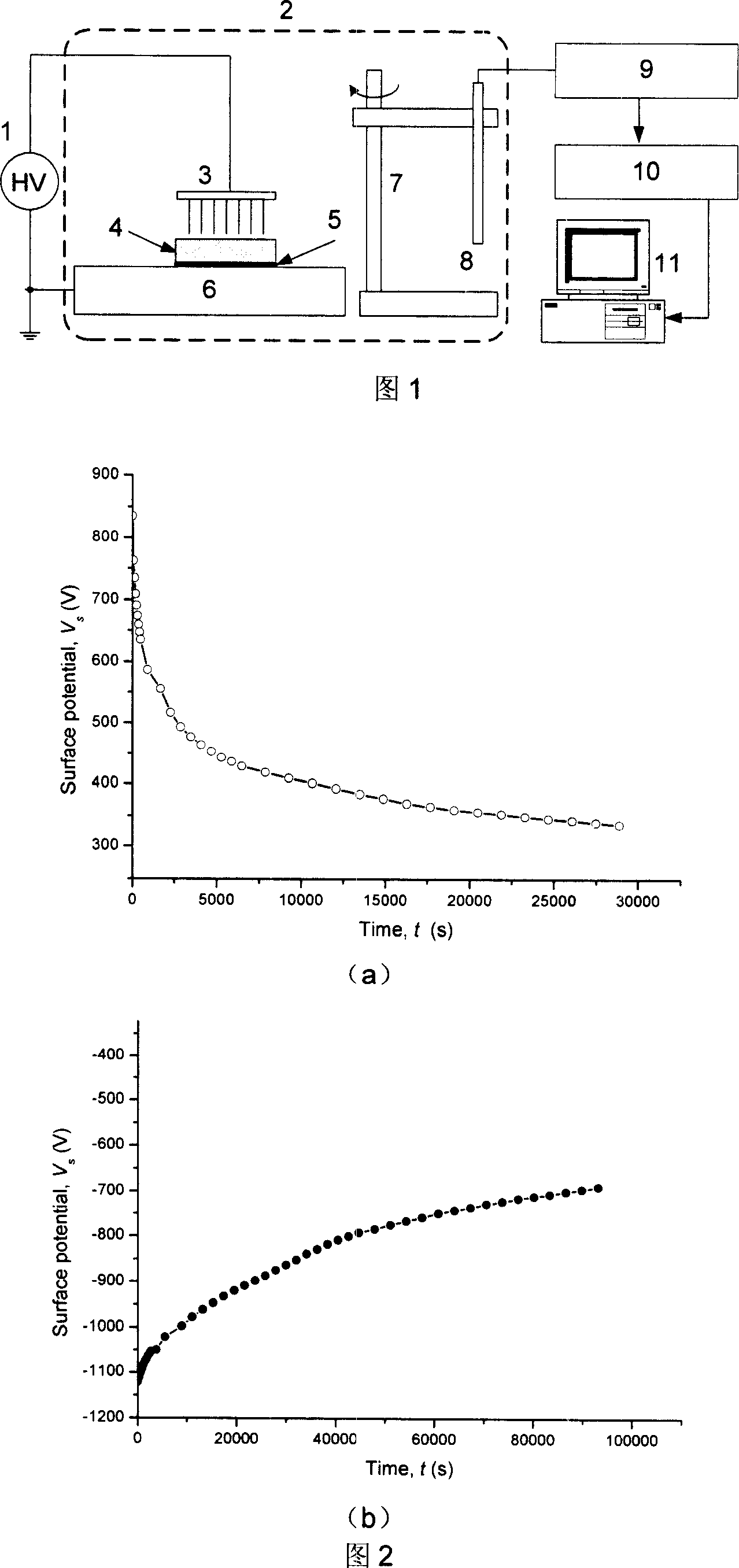

[0018] With reference to shown in Fig. 1, system of the present invention comprises an incubator 2, and incubator 2 inside has the metal disc electrode 6 of grounding, on the metal disc electrode 6 there is the polymer insulating sample 4 that is bonded by conductive silicone grease 5 , the top of the metal disc electrode 6 is also provided with a multi-needle electrode 3, which is connected with a high-voltage DC power supply 1; Type electrostatic probe 8, capacitive electrostatic probe 8 are connected with signal conditioning circuit 9, data acquisition circuit 10 and computer 11 arranged outside incubator 2 in turn.

[0019] During the experiment, the polymer insulating sample 4 was pasted on the metal disk electrode 6 with conductive silicone grease 5. The distance between the multi-needle electrode 3 and the surface of the polymer insulating sample 4 was about 2 mm. The high-voltage direct current power supply on the multi-needle electrode 3 1 Apply a DC high voltage of ±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com