Glue injection machine dedicated for biological plasticized silicone rubber

A silicone rubber and glue injection machine technology, applied in the application, plant preservation, botanical equipment and methods, etc., can solve the problems of difficult cleaning, machine blockage, etc., and achieve the effect of improving efficiency, convenient maintenance and good energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

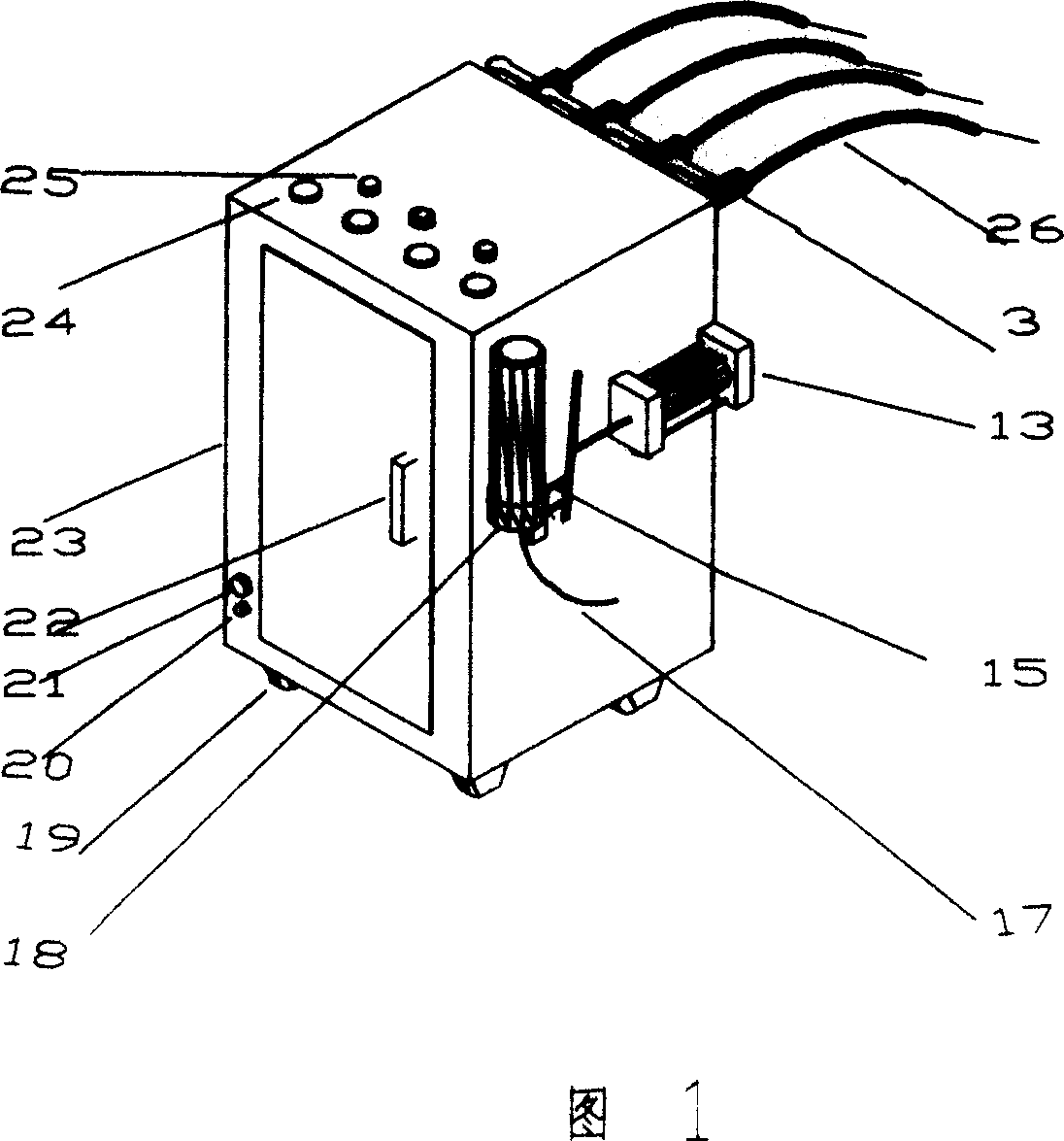

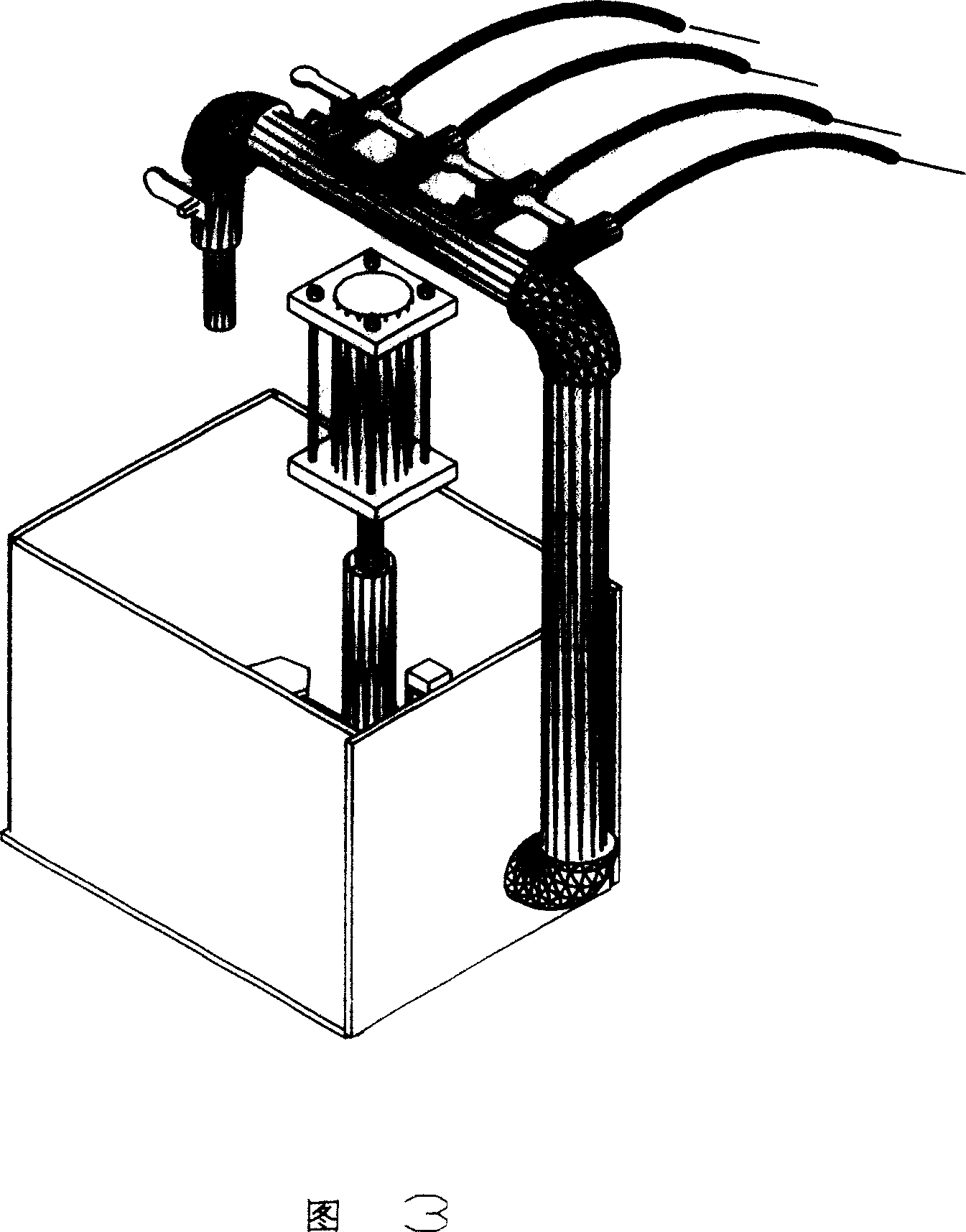

[0027] As shown in Figures 1, 2, 3, and 5, a special glue injection machine for bioplasticizing silicone rubber has a box body 23 in which a plunger pump is installed. Piston 9 and the one-way valve 7,11 of suction port, outlet are formed, and piston 9 is controlled by driving device, and driving device adopts pneumatic transmission, and the pneumatic piston rod of pneumatic cylinder 8 is connected with the piston rod of plunger pump. The pneumatic cylinder 8 can be controlled by the reversing valve 1 to move up and down the piston rod. The suction port of the plunger pump is placed in the silicone barrel 5, and the outlet of the plunger pump is connected with a delivery pipeline 2. The delivery pipeline 2 is arranged with four output pipelines. The output pipeline is equipped with a control valve 3, and the outlets of the output pipelines are respectively connected to A rubber hose 26, the end of the rubber hose 26 is connected with an injection needle. A pressure regulating...

Embodiment 2

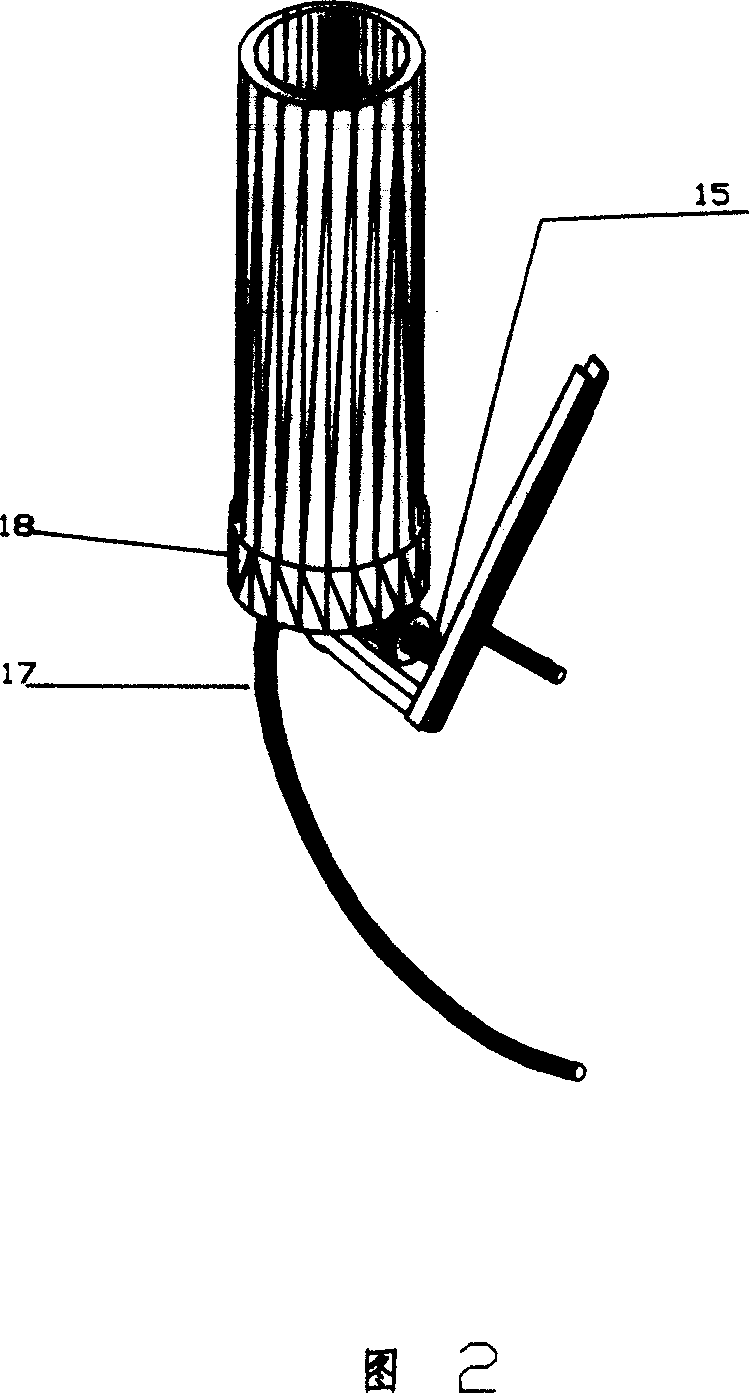

[0029] Others are as described in embodiment 1, only be provided with lifting plate on the outer side wall of casing 23, the silica gel dye container 18 (can be made of dry oil gun) of plug-in type is set on it, the bottom of container 18 is provided with sebific hose 17, and The container 18 is connected with a piston-type pressing device 15 , and the piston-type pressing device 15 is driven by a horizontal cylinder 13 . Horizontal cylinder 13 is also placed on the lifting plate. When working, the lifting plate can be pulled to the height of the workbench to reduce the length of the rubber hose, thereby reducing the resistance. The horizontal cylinder 13 makes the small piston in the pressing device 15 reciprocate in a push-pull manner, and the dye in the container is pressed into the rubber tube 17 and sent into the specimen body. After use, the container can be easily removed to clean up the solidified colloid. There is generally solidified colloid in the rubber tube at t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap