Printing registration test method

A detection method and technology for printing presses, applied in printing, printing presses, general parts of printing machinery, etc., can solve the problems of inability to comprehensively detect printing registration, not very intuitive, etc., to achieve intuitive detection results and improve labor efficiency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A printing registration detection method, the method comprises the following steps:

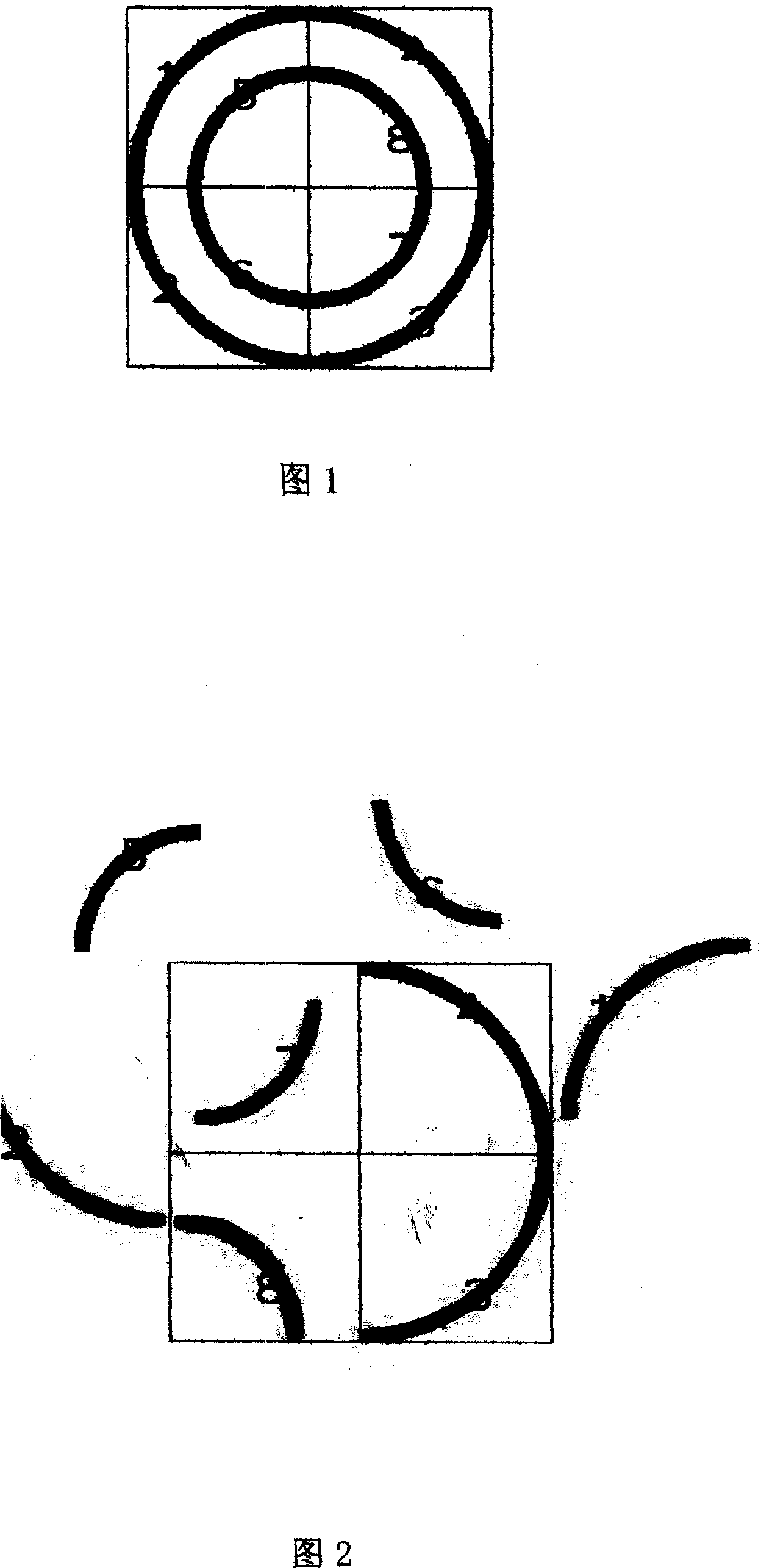

[0021] (1), during plate making, different colors are made in the same position of each color printing plate according to the form of concentric circles as shown in Figure 1, and the registration graphics of each color specified are printed on the printed matter;

[0022] (2) Install the detection equipment consisting of computers, cameras, etc. on the printing machine, and install the printing plates of each color on the printing machine to start printing. Since the initial positions of the printing plates of each color are random, standard registration marks may appear as shown in the attached picture In the figure shown in 2, the various colors will no longer be a concentric circle due to the change of printing position. After that, during the printing process, the camera installed on the printing machine captures the printing registration graphics and transmits the information to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com