Remote-control on-line monitoring system for universal movable crane

A working state and mobile lifting technology, which is applied in the system field of hoisting machinery technology, can solve the problems of inability to monitor and diagnose construction machinery, limitations, and the lack of versatility of the monitoring system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention is described in detail below: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments.

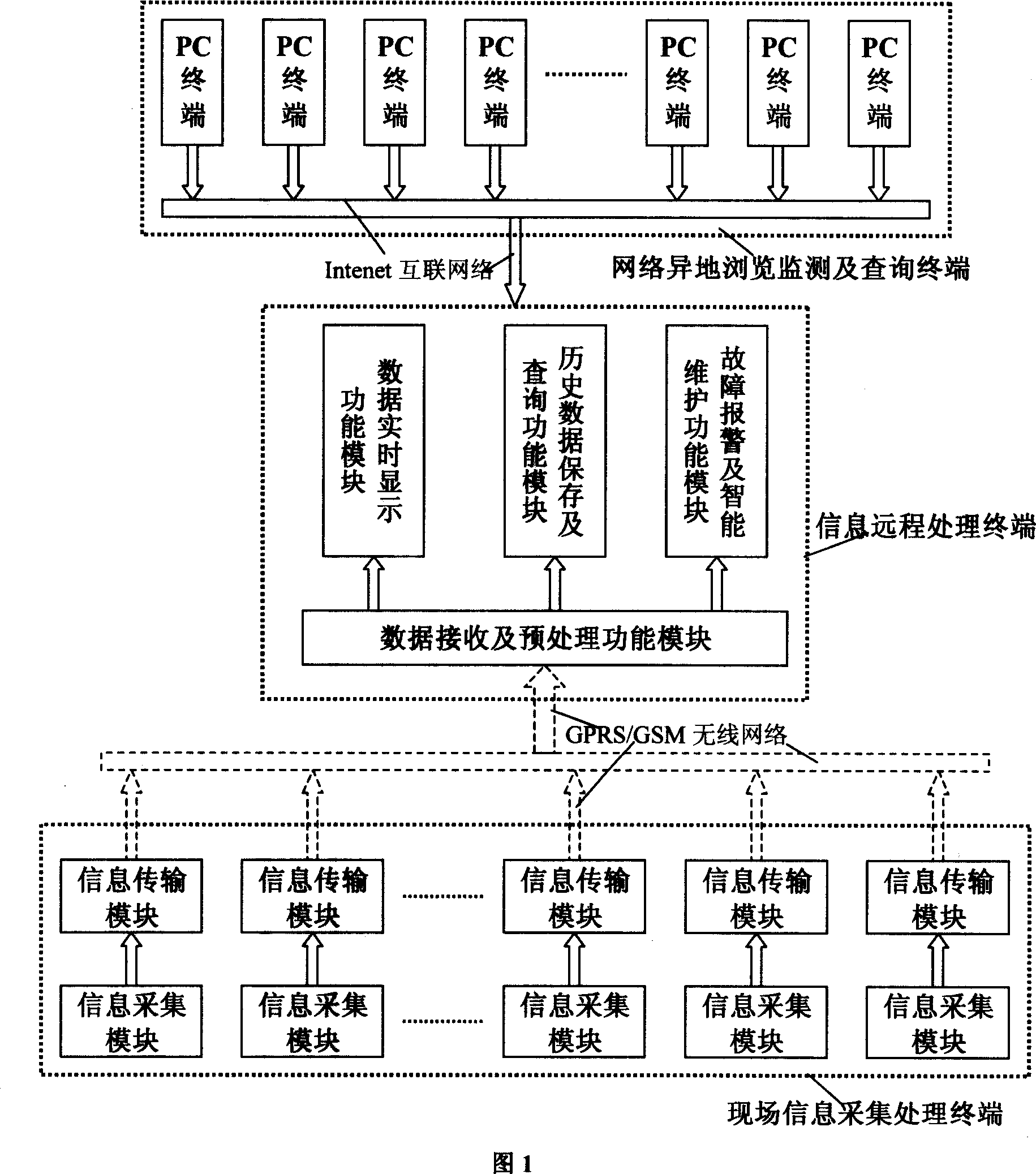

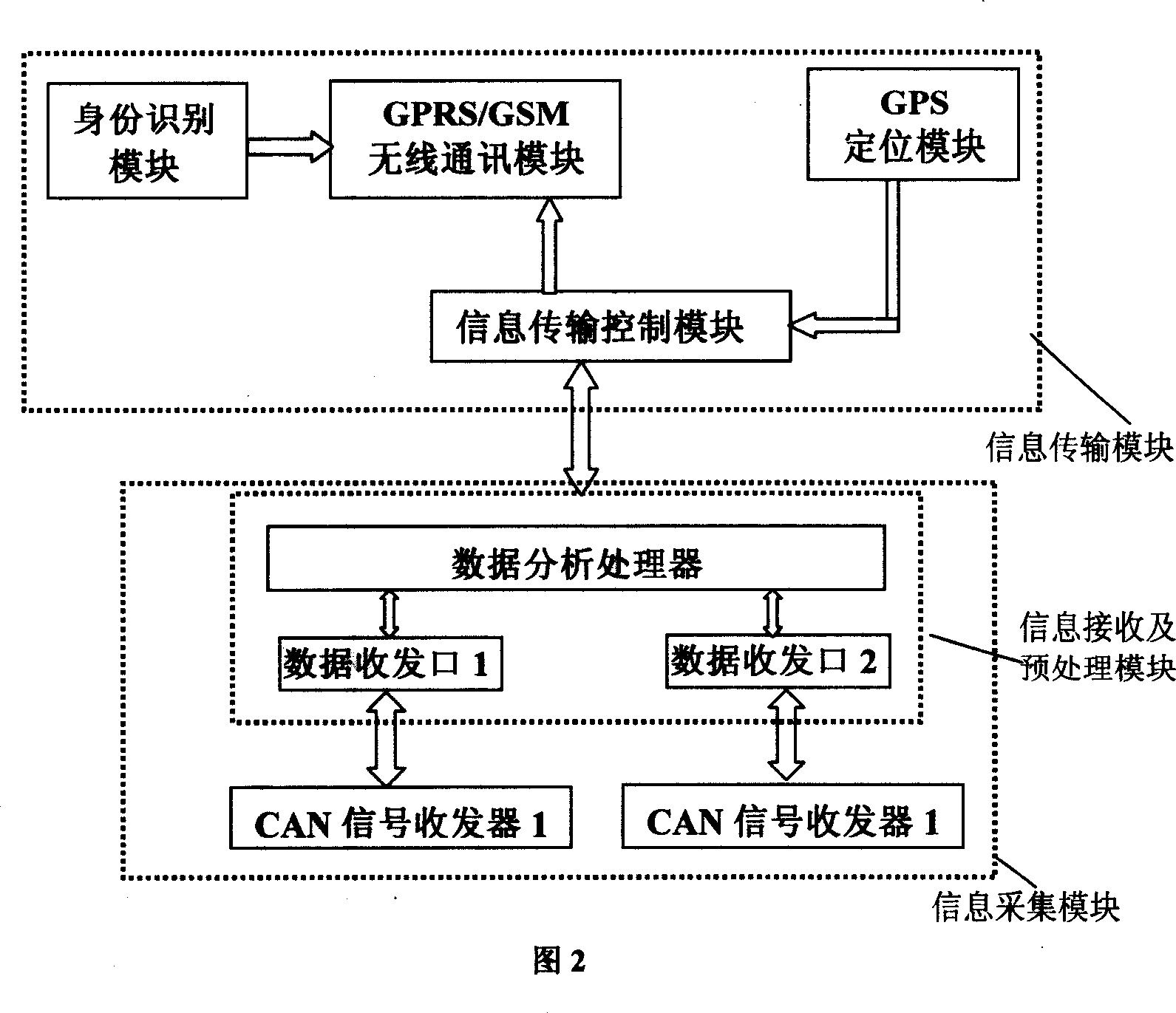

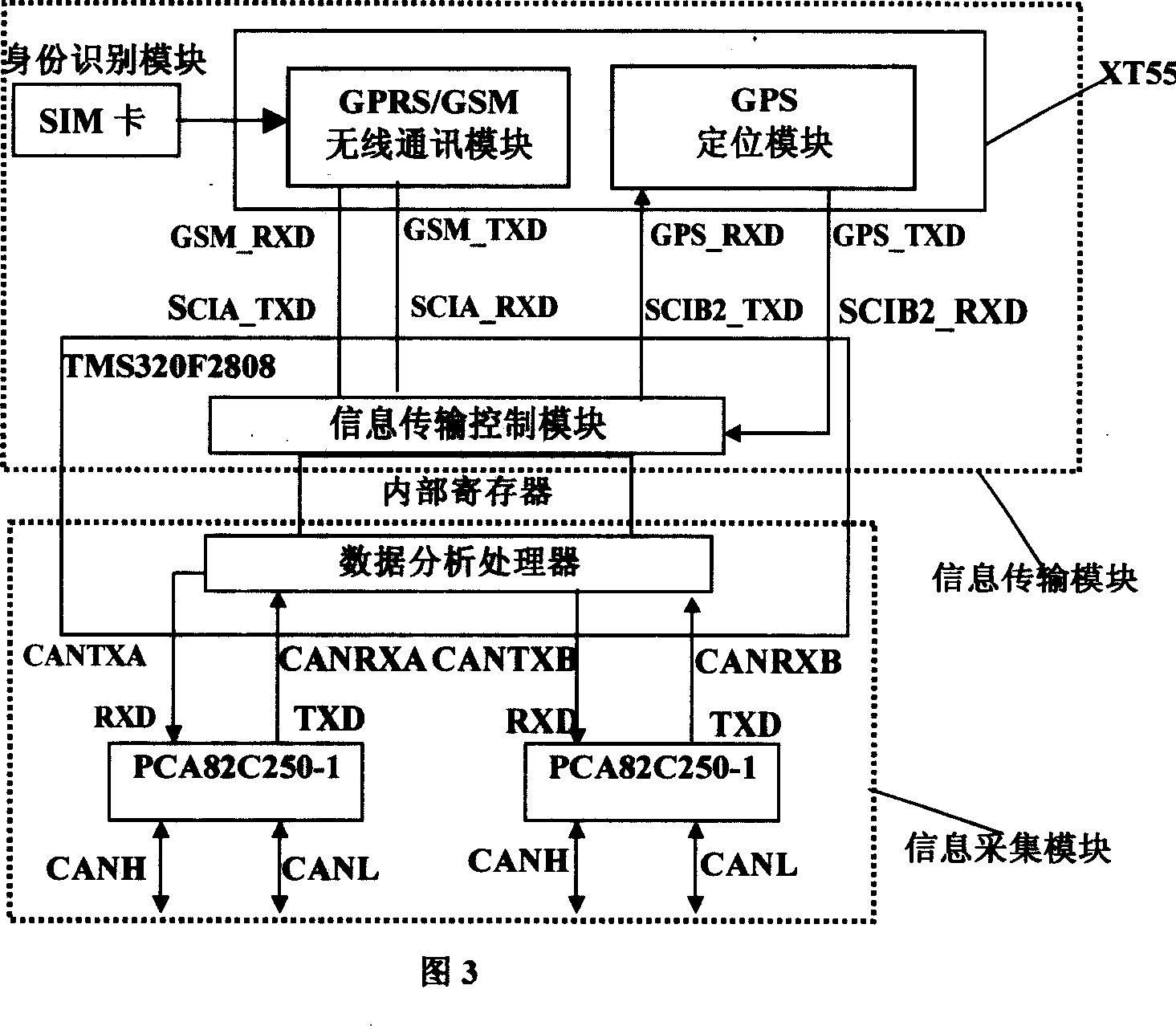

[0020] As shown in Figures 1 and 2: this embodiment includes: 1) an on-site information collection and processing terminal, 2) an information remote processing terminal and 3) a network remote browsing monitoring and query terminal. The on-site information collection and processing terminal is connected to the information remote processing terminal through the wireless GPRS / GSM network, and the network remote browsing monitoring and query terminal is connected to the information remote processing terminal through the Internet. The on-site information collection and processing terminal realizes real-time collection and preprocessing of the working st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com