Method of monitoring depositing temperature of cu seed layer and method for forming cu layer by using the same

A copper seed layer, deposition temperature technology, applied in thermometers, thermometers with physical/chemical changes, coatings, etc., can solve problems such as trouble and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

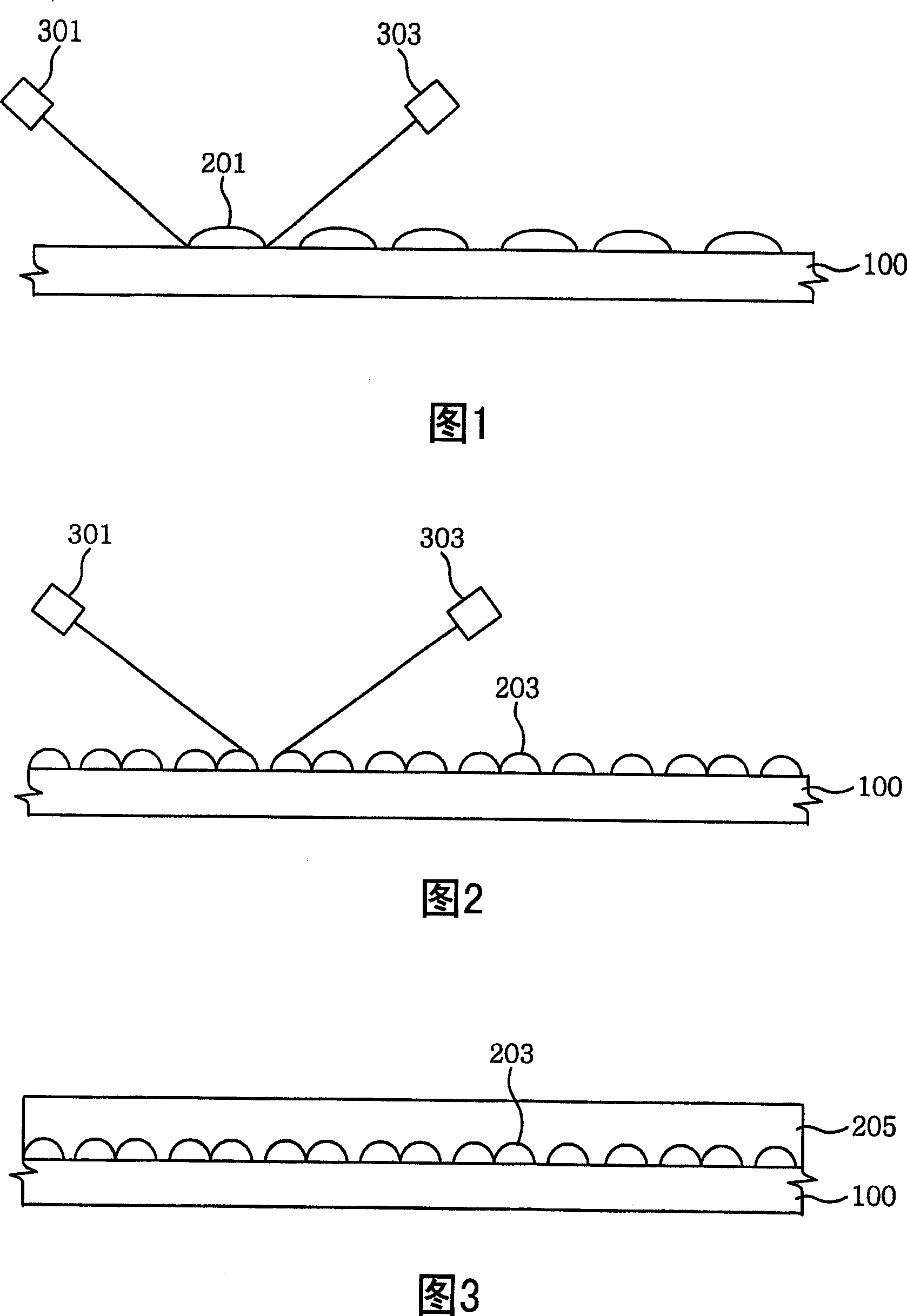

[0029] Embodiments of the present invention relate to a method capable of monitoring the deposition temperature of a Cu seed layer based on the light reflectance of the Cu seed layer. The embodiment of the present invention also relates to a method for forming a Cu layer.

[0030] According to an embodiment, after depositing the Cu seed layer, the light reflectance of the Cu seed layer is measured, so that it can be determined based on the measured light reflectance whether condensation has occurred in the Cu seed layer, thereby providing a Method for monitoring deposition temperature of Cu seed layer. This method of monitoring the deposition temperature of the Cu seed layer also prevents the subsequently electroplated Cu layer from being damaged due to the agglomeration phenomenon of the Cu seed layer.

[0031] Referring to FIGS. 1 and 2, a substrate 100 is installed in a Cu seed layer deposition apparatus (not shown). The first Cu seed layer 201 or the second Cu seed layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com