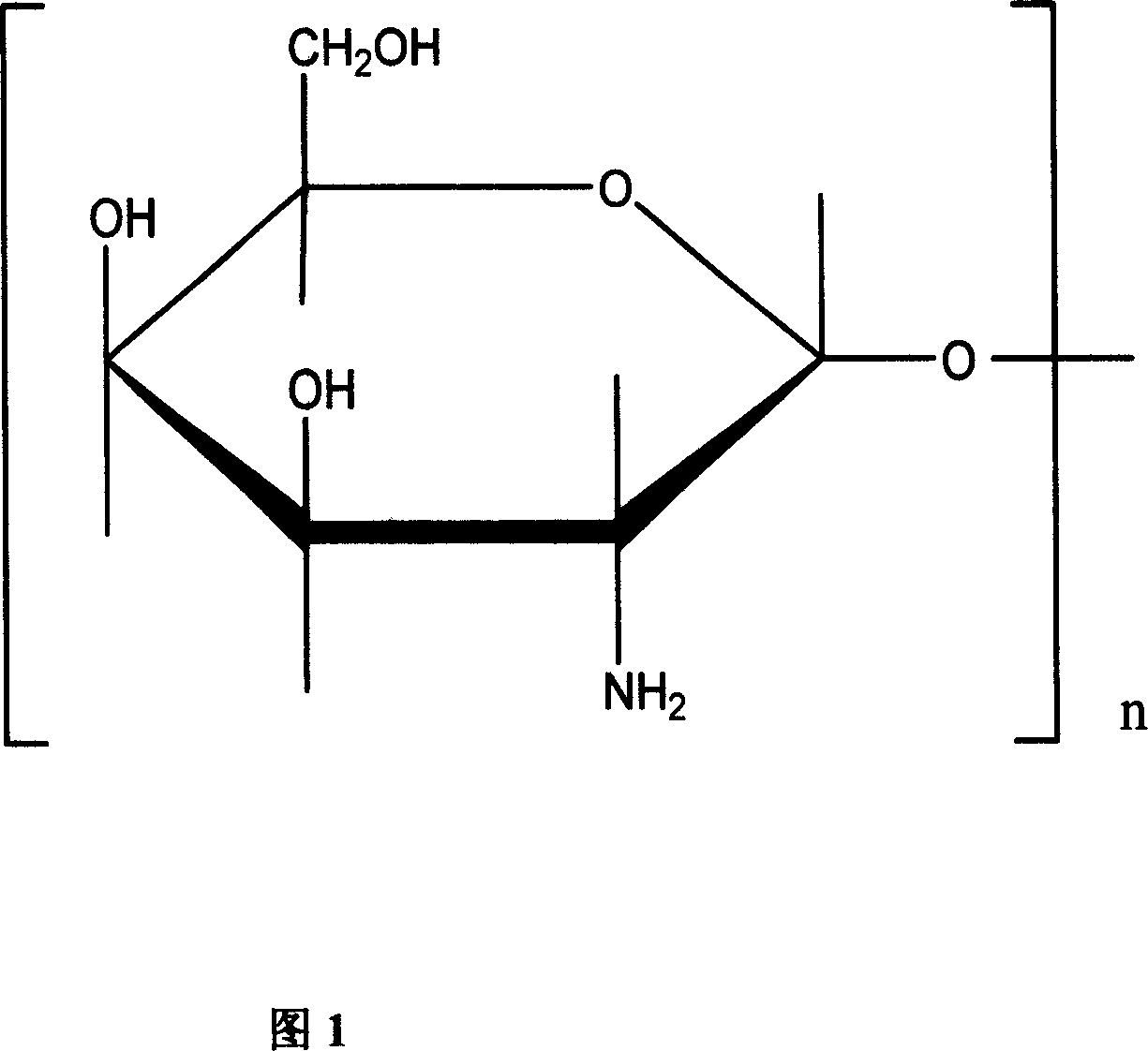

Method for reducing heavy metal in mussel boiling liquid by using chitose

The technology of cooking liquid and chitosan is applied to the reduction of heavy metals in mussel cooking liquid. The use of chitosan to treat heavy metals in mussel cooking liquid can solve the problems of great harm and animal poisoning, and achieve the reduction of heavy metal cadmium. and the effect of chromium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Get 35 ml of mussel cooking liquid, add 227 mg of chitosan, adjust the pH value of the solution to 7.5, heat for 7.3 hours at a temperature of 73 degrees Celsius and a shaking speed of 271r / min, then cool it at 4000r / min After centrifugation for 15 minutes, the supernatant solution obtained after filtration is the treated mussel cooking liquid. The cadmium content in the treated cooking liquor was reduced by 89%, and the chromium content was reduced by 21%. After testing, the processed mussel cooking liquid has met the requirements of export standards.

Embodiment 2

[0021] Get 35 ml of mussel cooking liquid, add 250 mg of chitosan, adjust the pH value of the solution to 7.0, and heat it for 7.5 hours at a temperature of 70 degrees Celsius and a shaking speed of 225 r / min, then cool it at 4000 r / min After centrifugation for 15 minutes, the supernatant solution obtained after filtration is the treated mussel cooking liquid. The cadmium content in the treated cooking liquor was reduced by 69% and the chromium content was reduced by 24%. After testing, the processed mussel cooking liquid has met the requirements of export standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com